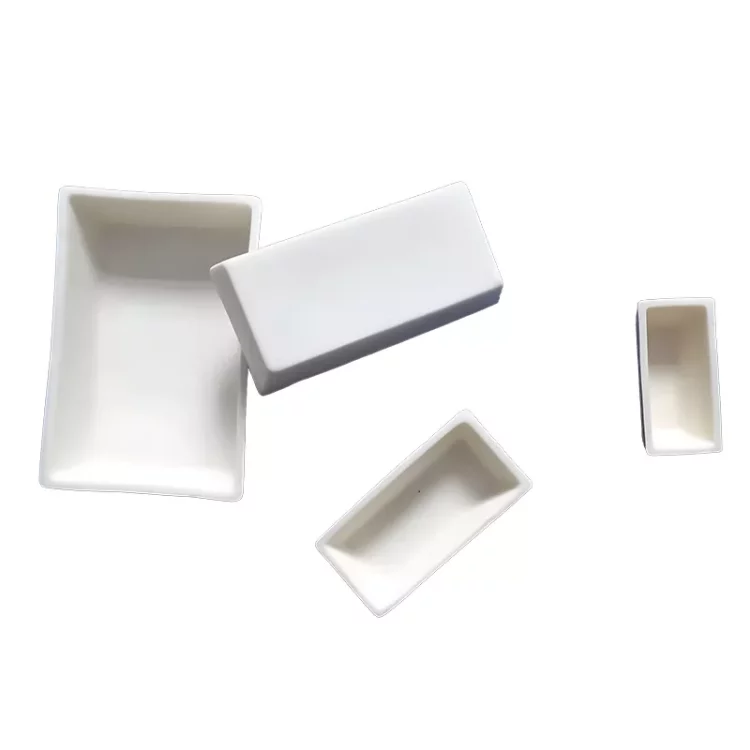

Custom Alumina Tray Solutions

GORGEOUS can customize the exclusive ceramic tray according to the actual application you provide.The following dimensions are for reference only to help you choose the most suitable alumina ceramic disc. If the size you need is not available, we can customize a solution for you.

Small capacity tray (1.5-25mL)

Applicable scenarios: precision experiments, trace sample processing

|

Capacity (mL) |

Dimensions (L×W×H, mm) |

Typical Applications |

|

1.5 |

25×15×5 |

Weighing of microreagents, Semiconductor chip placement |

|

5 |

40×30×15 |

Small melting experiment |

|

10 |

36×25×15 |

Chemical Vapor Deposition (CVD) Sample Holder |

|

25 |

50×38×20 |

Laboratory powder sintering |

Medium capacity tray (32–150 mL)

Applicable scenarios: Industry and scientific research

|

Capacity (mL) |

Dimensions (L×W×H, mm) |

Typical Applications |

|

32 |

75×50×11 |

Catalyst supported sintering, Electronic component packaging |

|

50 |

65×42×25 |

High temperature adhesive curing, Metal Heat Treatment |

|

100 |

80×56×30 |

Pharmaceutical industry intermediate drying, Glass glaze melting |

|

150 |

90×64×35 |

Ceramic slurry molding |

Large-capacity trays (250–750 mL)

Applicable scenarios: batch production and heavy-duty operations

|

Capacity (mL) |

Dimensions (L×W×H, mm) |

Typical Applications |

|

250 |

100×70×45 |

Catalyst supported sintering, Electronic component packaging |

|

500 |

150×80×55 |

High temperature adhesive curing, Metal Heat Treatment |

|

750 |

180×100×60 |

Pharmaceutical industry intermediate drying, Glass glaze melting |

Large capacity trays (1000–2000 ml)

Applicable scenarios: heavy industry and customized needs

|

Capacity (mL) |

Dimensions (L×W×H, mm) |

Typical Applications |

|

1000 |

190×110×60 |

For high temperature treatment |

|

1500 |

200×130×70 |

Semiconductor wafer sintering, Chemical reaction |

|

2000 |

210×140×80 |

Ceramic forming bearing, High temperature furnace |

Alumina Tray Description

In the realm of laboratory and industrial applications, high-purity alumina products stand as indispensable tools, renowned for their exceptional properties and wide-ranging versatility. These products, encompassing alumina trays, plates, dishes, boat crucibles, combustion boats, and ceramic crucibles, offer a unique blend of durability, thermal stability, and chemical resistance, making them ideal for a diverse spectrum of tasks.

Alumina tray crafted from high-purity alumina, provide a versatile platform for laboratory and industrial applications. Their exceptional thermal conductivity facilitates efficient heat transfer, while their resistance to chemical attack safeguards the integrity of experiments and production processes. Whether used for chemical calcination, metal casting, or ceramic sample preparation, alumina trays seamlessly adapt to diverse needs.

Alumina trays have excellent thermal conductivity, which helps to transfer heat efficiently. In addition, they can withstand temperatures up to 1600°C, and their strong chemical resistance helps to protect the integrity of experimental and production processes.

Alumina Ceramic Tray Material Parameters

| Property | Unit | AL2O3 99.7 | AL2O3 99.5 | AL2O3 99 | AL2O3 95 |

| Purity | — | 99.7% | 99.5% | 99% | 95% |

| Density | g/cm3 | 3.92 | 3.9 | 3.8 | 3.7 |

| Bending Strength | MPa | 375 | 370 | 340 | 304 |

| Compressive Strength | MPa | 2450 | 2300 | 2250 | 1910 |

| Elastic Modulus | GPa | 380 | 370 | 330 | 330 |

| Fracture Toughness | MPam1/2 | 4.5 | 4.3 | 4.2 | 3.8 |

| Hardness | HRA | 91 | 91 | 90 | 89 |

| Vickers Hardness | HV1 | 1600 | 1550 | 1450 | 1400 |

| Thermal Expansion Coefficient | 10- 6 K-1 | 7.8 | 7.8 | 7.7 | 7.5 |

| Thermal Conductivity | W/mk | 32 | 32 | 25 | 25 |

| Thermal Shock Stability | △T.℃ | 220 | 220 | 200 | 200 |

| Maximum Operating Temperature | ℃ | 1750 | 1750 | 1700 | 1500 |

| Volume resistance at 20℃ | Ω·cm | 1015 | 1015 | 1014 | 1014 |

| Dielectric Strength | KV/mm | 22 | 20 | 16 | 15 |

| Dielectric Constant (room temperature) | / | 10 | 11 | 11.5 | 11 |

| MHz Dielectric Loss Factor | tan δ | 1×10-3 | 1×10-3 | 3×10-3 | 3×10-3 |

*The table above shows typical properties for common alumina tray materials only. The properties of custom ceramic trays will vary depending on the purity and process selected.

Applications of Alumina Tray

- Semiconductor manufacturing wafer carrier

- Electronic component sintering support

- Photovoltaic solar cell production

- LED chip packaging and testing

- Precision ceramic component molding and sintering

- Chemical vapor deposition (CVD) process substrate tray

- Physical vapor deposition (PVD) process carrier

- High temperature environment material aging test carrier

- High temperature experimental carrier in vacuum environment

Detailed application introduction

High temperature furnace application: Alumina trays can withstand extremely high temperatures and are essential components in high temperature sintering furnaces, heat treatment furnaces and experimental furnaces. These trays can provide strong and durable support capabilities and can maintain their shape at high temperatures without deformation.

Electronic component manufacturing applications:During the manufacturing process of electronic components, alumina trays carry semiconductor chips, capacitors, resistors, and other parts. They ensure stable support and excellent insulation even at high temperatures.

Metal and ceramic powder sintering: The thermal conductivity of alumina trays is about 25-30 W/m·K (at room temperature). It can be used for the sintering process of metal powders and ceramic powders. The shape and superior performance of the tray can ensure that the materials can be evenly heated and treated at high temperatures.

Chemical experiments and production: In chemical experiments and production, good corrosion resistance allows ceramic trays to be used to carry chemical reaction materials and samples.

Powerful

GORGEOUS has passed ISO9001:2015 quality system certification, IATF 16949:2016 quality system certification, ISO14001:2015 environmental management system standard certification, and has jointly developed material products with many universities and obtained many patents, which means that we can provide you with higher quality products and services!

Our goal!

✅ Finished product qualification rate ≥ 95%

✅ On-time delivery rate ≥ 95%

✅ Customer satisfaction ≥ 99%

GORGEOUS ensures consistent quality control, from raw materials to parts, from products to projects, we pay attention to details, solve problems, research new materials and new processes, invest in technology, and build a professional production team.

- Design for Manufacturing (DFM) review for all your projects

- Contract and purchase order review

- Production capacity and production plan review (PMC)

- Incoming raw material inspection

- Sample and process inspection (IPQC)

- Control of non-conforming products and implementation of corrective and preventive measures

- Final inspection and test reports and certificates (OQC) required

- Customer satisfaction survey twice a year, strive to exceed customer expectations

We Can Provide You With

A variety of purity options: 95%-99.7% high-purity alumina trays are available for you to choose.

- 95% alumina trays–your economical solution, suitable for conventional industrial heat treatment, GORGEOUS’s cost-effectiveness is 15% higher than the industry

- 99.5% and above alumina trays–your high-precision ceramic tray choice, perfect for semiconductor, chemical and other industries

Customized service: Ceramic trays of various specifications and sizes can be customized according to your drawings and requirements.

- 24-hour engineering team response (except weekends)

- Support special processing - laser marking, inner wall polishing, embedded platinum temperature measurement hole design

- Progress visualization - give customers a transparent production experience, 3D design renderings confirmation, production progress report

Free samples: Free sample testing is provided.

- Bulk orders can be deducted from the free sample fee

- Free consultation after sample testing

Package

We carefully pack each product to prevent the goods from being damaged during transportation. We ensure that the ceramic trays delivered to you are of high quality and complete.

Contact us now!

If you need high-quality alumina ceramic trays, please contact us immediately and we will serve you wholeheartedly!