Customized Ceramic Plunger Manufacturers

Ceramic plungers are available in standard, short plunger, long stroke, ball, push-in and press-in styles. Applications include positioning, indexing, metering, locking, control, etc. Gorgeous custom precision manufactured products.

High Quality/ High Value.

Ceramic Plunger

Gorgeous Advantage

Custom Ceramic Plunger In China

Ceramic plungers are precision parts made of high-purity ceramic materials. After fine processing, their surfaces have low friction coefficients and high sealing properties, and can maintain long-term operation even under high pressure and high speed conditions. In addition, the chemical inertness of ceramic plungers can withstand various acids and alkalis, and are particularly suitable for precision equipment in your chemical, pharmaceutical, and food processing sites.

GORGEOUS ceramic plungers meet international industrial standards. Our ceramic plungers can be specially customized according to your specific requirements, including different diameters, lengths, and special requirements for surface treatment processes. Whether often used in precision pumps, valves, or other high-precision equipment, GORGEOUS ceramic plungers can provide your equipment with excellent performance and long life.

Ceramic Plunger

Products

Guarantee Manufacturing & Shipping Time

GORGEOUS has more than 15 years of experience in producing ceramic plungers and can provide you with high-quality plunger customization services.

Your plunger will go through four processes: manufacturing, packaging, loading, and transportation, and each process is transparent and visible.

The manufacturing and transportation of ceramics are affected by the process and your location. We will quickly manufacture them for you according to your plan and choose the best transportation method. The fastest delivery time in North America is 7 days.

GORGEOUS chooses to cooperate with several leading logistics companies, including:

- MSC (Mediterranean Shipping Company)

- Maersk

- CMA CGM

- COSCO

- Hapag-Lloyd

We work with multiple freight forwarders to guarantee you efficient shipping options at lower prices, on-time delivery, and no hidden fees!

Manufacturing

Packing

Loading

Transportation

Ceramic Plunger Function Box

Wear-resistant

Ceramic plungers have excellent wear resistance, and some materials are also self-lubricating.

Lightweight

Compared with metal plungers, ceramic plungers are lighter and more.

Corrosion Resistance

Ceramic materials resist various corrosive substances and ensure long service life.

High temperature resistance

Ceramic plungers are stable at high temperatures and suitable for a variety of high temperature applications.

Customize ceramic plungers in bulk for you!

GORGEOUS always maintains the highest standards in the manufacture of ceramic plunger and cummins ceramic plunger ceramic piston pumps. Our professional team will carefully study the drawings you give us and maintain extremely high precision on the shape, key dimensions, diameter, length, etc. of the plunger. The processing accuracy reaches ±0.001mm. You can rest assured to hand over the task to us. We ensure that your plunger can operate accurately and stably in complex and harsh environments.

Surface roughness is one of the key indicators to measure the working quality of the piston, which helps to reduce the friction and wear of the plunger. We use the most advanced ultrasonic processing and laser technology to make your ceramic plunger and cummins ceramic plunger surface finish Ra less than 0.1μm!

GORGEOUS Machining Accuracy Reference

| Dimensional accuracy | Up to 0.001mm |

| Finish | Up to mirror surface |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| Inner hole tolerance | Can process 0.005mm |

| Straight slot | Can process groove width up to 0.1×100mm |

| Thickness | Can be processed to 0.3mm |

| Thread | Can process internal thread M2, external thread is not limited |

| Cylindricity | Up to 0.004mm |

| Linear tolerance | Up to 0.001mm |

| Minimum aperture | Processable 0.5mm (mold opening 0.1mm) |

*The specific accuracy needs to be determined according to the actual product material, shape and process requirements.

Comparison of Plungers of Different Materials

| Material | Alumina(AI2O3) | Zirconia | Silicon Nitride | |||

| Purity(%) | 99.99 | 99.7 | 99 | 95 | 94.4 | – |

| Mohs hardness | 9 | 9 | 9 | 8.8 | – | 9 |

| Compressive strength(Mpa) | 3500 | 2000 | 1600 | 1200 | 2000 | 3800 |

| Fracture toughness(MPam1/2 ) | 4 | 4 | 4 | 4 | 4 | 5 |

| Tensile Strength(Mpa) | 300-500 | 200-300 | 100-250 | 70-150 | – | – |

| Bending Strength(Mpa) | 500-600 | 250-350 | 100-250 | 100-150 | 700-1500 | 700 |

| Elastic modulus(Gpa) | 400 | 380 | 330 | 300 | 200-210 | 450 |

| Poisson’s ratio | 0.23 | 0.23 | 0.22 | 0.2 | 0.3 | 0.14 |

| Material | Alumina(AI2O3) | Zirconia | Silicon Nitride | |||

| Purity(%) | 99.99 | 99.7 | 99 | 95 | 94.4 | – |

| Density(g/cm3 ) | 3.97 | 3.93 | 3.9 | 3.7 | 6.02 | 3.25 |

|

Coefficient of thermal expansion (25℃-800℃)10-6 /℃ |

7.5-9.5 | 8.2-10.2 | 8.0-9.8 | 8.5-10.5 | 9.6 | – |

|

Coefficient of thermal expansion (25℃-300℃)10-6 /℃ |

6.5-8.0 | 7.2-8.7 | 7.0-8.5 | 7.5-9.0 | 10 | 3.2 |

| Maximum stable operating temperature(℃) | 1750 | 1700 | 1500 | 1500 | 200 | 1100 |

| Thermal conductivity(Normal temperature25℃)W/(m·k) | 45 | 30 | 20 | 15 | 3 | – |

| Thermal conductivity(high temperature1000℃)W/(m·k) | 30 | 20 | 15 | 10 | – | – |

| Dielectric constant | 10 | 9 | 8 | 7 | 14 | 14 |

| Resistivity(25℃) | >1014 | >1014 | >1014 | >1014 | >1012 | – |

Why Choose GORGEOUS Custom Ceramic Plunger

GORGEOUS has many years of experience in production and processing technology. We have been focusing on the processing of ceramic products, improving technology, energy saving and efficiency, and reducing costs.

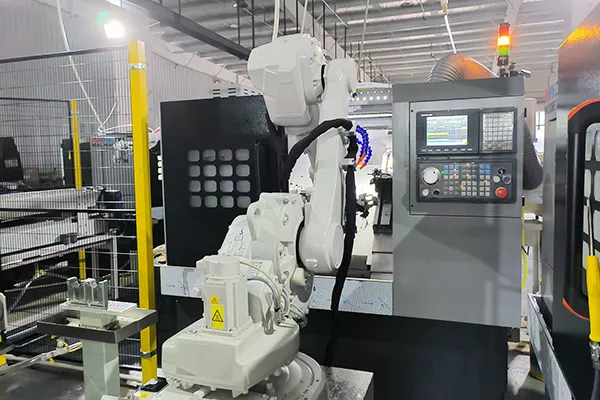

Our team has 32 professional engineers and 8 experts. At the same time, we are equipped with various advanced manufacturing technologies and equipment, three-dimensional coordinate detection machines, 3KW optical laser cutting machines, 3DCNC processing and other equipment, which enables us to better customize exclusive Ceramic plunger for you.

All our Ceramic plunger have been seriously tested and meet ISO and CE standards.Don’t worry about your products being accidentally transported, we carefully package your products.We provide you with perfect after-sales service if there are serious quality problems with the product.

We provide ceramic pistons of various sizes, designs, structural standards, and non-structural standards. If you need to customize Ceramic plunger, please contact us immediately!

Application Areas of Ceramic plunger

Chemical Industry

Ceramic plunger pumps can be used in the chemical industry, such as metering pumps, chemical pumps, etc. They are resistant to corrosion from strong acids and alkalis and can work stably in harsh environments.

Industrial

Ceramic plungers can be used in various industrial equipment. Their wear-resistant and lightweight characteristics can effectively improve efficiency, such as high-pressure cleaners, automotive parts, etc.

Energy Industry

In various power plants and renewable energy systems, ceramic plunger are used in high-pressure pumps, compressors and other equipment. Due to the various superior properties of ceramic plunger, they are very suitable for high-pressure work in harsh environments.

Medical Industry

Various common medical devices also fall within the application range of ceramic plunger. For example, some high-precision pumps and injection equipment, high-pressure syringes, drug delivery devices, etc. can use ceramic plunger.

Mud/Oil Industry

Ceramic plungers are hard and wear-resistant, and are commonly used in various hydraulic pumps, sand pumps, mining pumps and other equipment. They have good wear resistance, reduce wear in various slurries, and have a longer service life than metal plungers.

One-stop Ceramic Plunger Parts Manufacturing Service

15+ Years of Experience. High Precision and OEM Design. Professional R&D Team. Competitive Price.

What do you need to provide for custom Ceramic plunger?

You only need to send us an inquiry and provide the most basic information and drawings. Our team will provide you with various professional suggestions and customize a unique Ceramic plunger for you.

How about after-sales service?

We are a company that values integrity and enjoys a high reputation in the industry. We focus on long-term cooperation with customers. Our products are of high quality and delivered quickly. We will do our best to provide you with after-sales service!

If your product is damaged or scratched due to packaging problems, we will compensate you! If your product has serious quality problems, we will compensate you! Please rest assured to cooperate with us.

How to maintain the ceramic plunger?

You need to clean the surface of the ceramic plunger regularly to remove residual dirt, etc., to prevent unnecessary scratches on the plunger during operation. In addition, you can also regularly check whether the surface of the ceramic plunger has cracks, wear, etc. If it is severely worn, you need to replace the plunger in time to prevent the equipment from malfunctioning during operation. If you apply a specific lubricant on the surface of the plunger, you can protect the plunger to a great extent and reduce loss.