Ceramic Core

Ceramic cores are often used to produce complex metal parts, often in industries such as aerospace, automotive and turbine manufacturing.

Affordable price and excellent quality!

Ceramic Core

Ceramic product display

Ceramic Valve Core

ICommonly used in applications such as faucets, automotive systems and industrial control valves.

Heat Resistant Al2o3 Alumina Ceramic Core Grind Parts

Thermal shock and oxidation resistance.

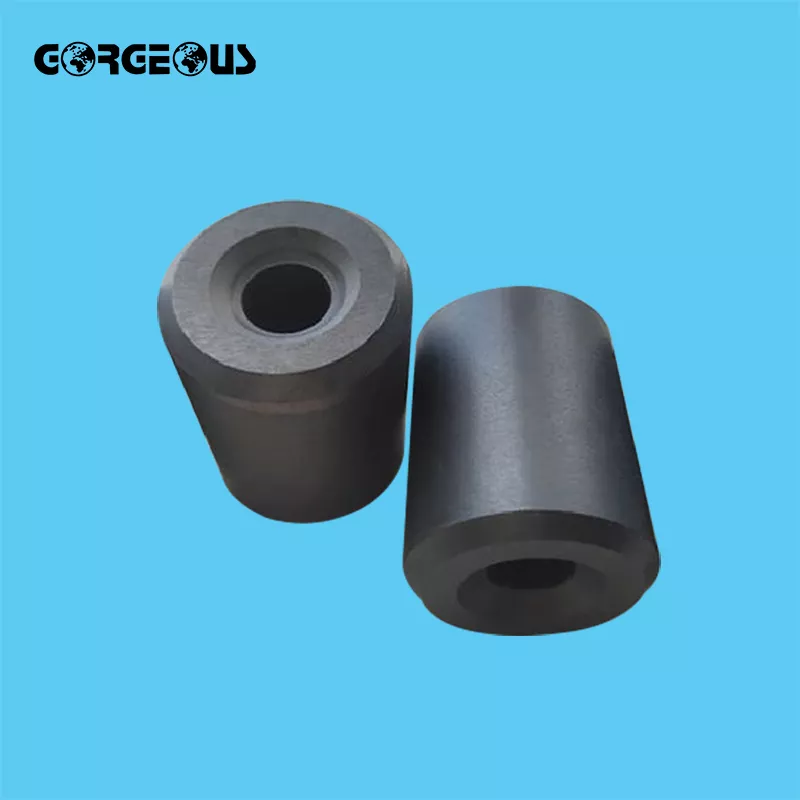

Boron Carbide Nozzle Core Gun Core

Able to withstand continuous impact from abrasives without degradation.

Boron Carbide Spray Gun Ceramic Nozzle

Boron Carbide Sandblasting Machine Nozzle Ceramic Nozzle Core

Highly durable and abrasion resistant.

Ceramic Grinding Core

Provides hardness, wear resistance, and the ability to operate effectively at high speeds and temperatures without degradation.

Zirconia Ceramic Shaft Sleeve

With excellent hardness and fracture toughness, the smooth surface reduces friction and prevents damage.

Alumina Junction Box Core

It has excellent electrical insulation properties, mechanical strength and thermal stability.

What is a ceramic core?

Ceramic cores are components made of ceramic materials that are commonly used in the manufacturing and engineering industries to produce complex metal parts. Their main use is to provide support during the casting process and are suitable for industries such as aerospace, automotive and turbine manufacturing.

The ceramic cores we produce have a long service life and are well received by customers. They can help you reduce the maintenance costs of your equipment. Choosing our ceramic cores means you can get a longer return on investment with less investment.

The ceramic cores we produce are reliable and durable. As long as you provide the drawings, our professional team can customize your exclusive ceramic core. Please be sure to choose GORGEOUS!

Ceramic Core Products Of Various Materials

99 Alumina Thermocouple Insulation Core

Used to insulate thermocouple wire and protect it from external environmental factors.

K-Type Thermocouple Ceramic Core

Prevent electrical interference and maintain stability in thermocouple temperature readings.

Silicon Nitride Insulation Ceramic Positioning Core

Combines strength, thermal stability and wear and corrosion resistance for use in high temperature systems.

Silicon Nitride Ceramic Core Ignition Rod

Excellent durability, thermal stability and performance in high temperature ignition systems.

Fiber Optic Ceramic Ferrule

Used in various fiber optic components to ensure the performance and reliability of fiber optic communication systems.

Boron Carbide Spray Gun Ceramic Nozzle

Essential for industries requiring high-precision spraying and sandblasting.

Ceramic Plug-In Core

Provides electrical insulation and thermal conductivity, helping to prevent thermal damage and transfer heat quickly.

Ceramic Soldering Iron Core

With high temperature resistance, it provides efficient heat transfer and ensures stability and durability.

Ceramic Core

Gorgeous Advantage

- Can meet the demand for high-purity customized structural parts;

- It has a Class 10,000 clean room to improve performance in a clean environment;

- The maximum surface is Ra0.010 micron;

- With 90 sets of precision processing equipment and 20 years of experience;

- Waiting for you to place an order with the minimum precision tolerance of structural parts and challenge the ultimate tolerance and precision;

Application Areas Of Ceramic Core

- Electronics and electrical industry

- Automotive industry

- Metal processing and heat treatment

- Energy and chemical industry

- Laser and fiber optic technology

- Aerospace

- Medicine and biotechnology

- Precision instruments and testing equipment

Why Choose GORGEOUS Custom Ceramic Core?

GORGEOUS has many years of experience in production and processing technology. We have been focusing on the processing of ceramic products, improving technology, energy saving and efficiency, and reducing costs.

Our team has 32 professional engineers and 8 experts. At the same time, we are equipped with various advanced manufacturing technologies and equipment, three-dimensional coordinate detection machines, 3KW optical laser cutting machines, 3DCNC processing and other equipment, which enables us to better customize exclusive Ceramic core for you.

We provide ceramic cores of various sizes, designs, structural standards, and non-structural standards. If you need to customize Ceramic core, please contact us immediately!