Beryllium Oxide Ceramic

Beryllium oxide ceramic is also called BeO ceramic, and its raw material is beryllium oxide ceramic. Its chemical formula is BeO, which is beryllium oxide. Beryllium oxide is amphoteric. Can react with acid and alkali. Beryllium oxide is sintered at a certain temperature to form BeO ceramics. Its thermal conductivity is 10 times that of alumina.

Excellent Performance!Powerful Price!

Beryllium Oxide Ceramic

Gorgeous Advantage

Your Trusted Beryllium Oxide Ceramic

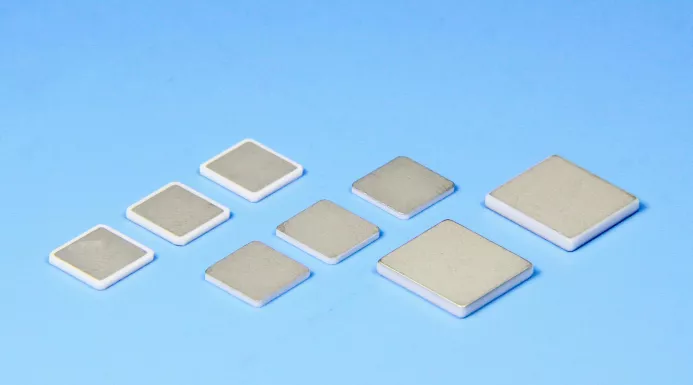

In most people’s minds, beryllium oxide raw materials are toxic, which makes its safety requirements in the powder preparation process strict. But when beryllium oxide is converted into its ceramic form, it becomes non-toxic. The thermal conductivity of beryllium oxide ceramics is 10 times that of alumina ceramics. It has low dielectric constant and dielectric loss, reliable insulation performance, high temperature resistance, chemical corrosion resistance, thermal expansion coefficient and silicon support, high packaging reliability, and is widely used in Microelectronics and packaging, communication devices, high-brightness LEDs, power electronic modules and other industries. Specifically, there are beryllium oxide porcelain rods, cylinders, tiles, plates, columns, rods ,beryllium oxide crucibles ,beryllium oxide attenuating ceramics and beryllium oxide ceramic metallization. The company can produce products of various specifications and models according to customer requirements.

Beryllium Oxide

Ceramic Product Display

Gorgeous product

Beryllium oxide is relatively rare compared to other ceramic products, but it has many uses. Beryllium oxide ceramics have excellent thermal conductivity and electrical insulation, and are also radiation-resistant. They are widely used in industry and the nuclear industry.

beryllium oxide substrate

Feedthrough/Ceramic to Metal

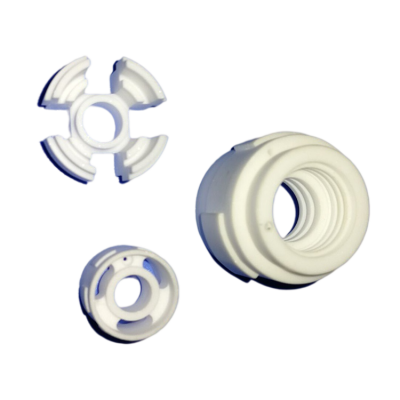

beryllium oxide ring

Features of BeO Ceramic

Excellent Thermal Conductivity

BeO ceramic exhibits extremely high thermal conductivity, rank only second to silver and copper, making the highest thermal conductivity of all ceramic materials.

Electrical Insulation

Beo ceramic also has high resistivity and high breakdown strength, low high-frequency loss, and low dielectric constant.

High Temperature Stability

BeO ceramic can withstand high temperatures without significant degradation, making it suitable for use in demanding thermal environments.

Mechanical Strength

BeO ceramic possesses excellent mechanical properties, including high hardness, good tensile strength, and resistance to deformation under mechanical stress.

Applied for High-end Products

Beryllium oxide material properties

| Name | Beryllium oxide | |||

| Dielectric constant | 1MHz | 6.9士0.4 | ||

| Dielectric loss tangent | 1MHz | ≤4×10^-4 | ||

| Volume resistivity | 25℃ | ≥10^14 | ||

| 300℃ | ≥10^11 | |||

| Breakdown strength | D.C | >20 | ||

| Flexural strength | – | ≥190 | ||

| Thermal conductivity | 100℃ | ≥190 | ||

| Average linear expansion coefficient | 25℃~500℃ | (7.0~8.5)×10^-4(1/K) | ||

| Average grain size | – | 12~30 | ||

Why choose our beryllium oxide ceramic related products

We focus on the manufacturing and sales of various engineering ceramic products, including alumina ceramics, boron nitride ceramics, silicon nitride ceramics, etc. Some of the company’s products are unique and irreplaceable and are widely used in nuclear industry, chemical industry, aerospace, electronic communications and other fields.

Our ceramic product production is equipped with full-process precise monitoring and various online testing instruments, such as laser particle size distribution tester, powder comprehensive performance tester, and three-coordinate tester, to implement full-process control from raw materials, manufacturing processes to accuracy. The company adopts “6S” management, focusing on prevention and continuous improvement, adhering to the goals and management system of “advanced technology, high-quality products, and high-grade services”.

GORGEOUS is your BeO ceramic product supplier in China. We manufacture flawless custom parts at attractive prices. If your business or project requires BeO ceramic products, you’ll find the ideal product at Gorgeous.

BeO Ceramic For Different Industries

Please note that our beryllium oxide products may be unique and irreplaceable.

Insulating material

Beryllium oxide ceramic has excellent insulation and thermal stability and is often used in the manufacture of electronic packaging and high-voltage electronic devices.

Military & Defense

BeO ceramic is employed in components such as missile guidance system, and thermal management system, where high temperature stability and thermal conductivity are crucial.

Energy

It finds applications in power generation and energy conversion systems, including thermal power plants, nuclear reactors, and high-power lasers due to its ability to withstand high temperatures and efficiently dissipate heat.

Aerospace

Beryllium oxide ceramics are lightweight and very strong, which is very suitable for the aviation industry and is used to manufacture aerospace insulation materials, etc.

High-temperature Applications

Beryllium oxide ceramics are used in industries that require high temperature stability and superior thermal conductivity, and are often made into products such as heat sinks and thermal pads.

One-Stop Beo Ceramic Manufacturing Services

15+ Years of Experience. High Precision and OEM Design. Professional R&D Team. Competitive Price.

Is beryllium oxide anti-radiation?

Beryllium oxide ceramics have excellent radiation resistance and are often used in the nuclear industry and aviation fields. However, long-term radiation exposure will cause radiation hardening. However, beryllium oxide ceramics still have good radiation resistance.

What is the thermal conductivity of beryllium oxide?

The thermal conductivity of beryllium oxide ceramics is very high, and its thermal conductivity is about 200 - 300 W/(m·K), which is quite high among many ceramic materials. Excellent heat dissipation properties allow it to be used as a high-temperature insulation material and part of a thermal management system. In addition, the thermal conductivity of beryllium oxide ceramics is also used in the aerospace field to make thermal conductive materials and thermal insulation materials. This is because beryllium oxide ceramics can still maintain stable performance even in extreme environments.

What is the formability of beryllium oxide ceramics?

Beryllium oxide ceramic is not prone to thermal expansion or contraction at high temperatures, making it dimensionally stable. At the same time, the molding performance of beryllium oxide ceramics is also very good, and various complex properties and structures can be completed well.

Can beryllium oxide be customized?

We can provide you with customized services. Our professional team can customize based on the drawings you provide to meet your special needs and provide you with technical support and advice.