Metallized Ceramic

Our metallized ceramics are produced in a Class 10,000 clean room environment.

Welcome to place orders in bulk, large quantity and good price!

Metallized Ceramic

Gorgeous Advantage

Your Metallized Ceramic Supplier

The surface of metallized ceramics is covered with a metal coating, which has superior performance than ordinary ceramics. It shines in the fields of electronic devices, chemical equipment, aerospace devices, medical equipment, optical devices and other fields.

We are your trustworthy metallized ceramics supplier in China. With reasonable prices and superior quality, we are your best choice now.

If you have a business or project that requires metallized ceramics, please contact us, we have a variety of products for you to choose from.

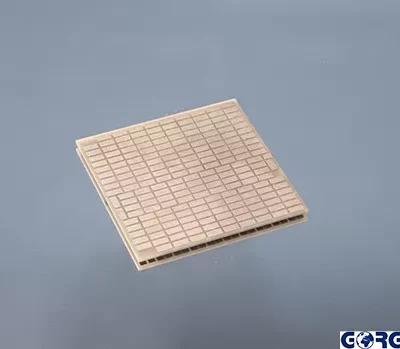

Metallized Ceramic

Product Display

Latest products similar to Metallization Feedthrough

The feedthrough adopts ceramic-metal brazing process. The ceramic is made of zirconia/alumina composite ceramic or silicon nitride ceramic with more reliable performance, and is brazed with precious metal solder containing gold, nickel, palladium and other ductility. The tightness temperature can exceed 550℃. The air tightness of the ceramic feedthrough reaches 1.5*10-10Pam3/s. The leakage rate of 500℃/10 hours is within the safe range.

Feedthrough

Metallized Ceramic Feedthru

Feedthrough

Features of metallized ceramics

Electrical Conductivity

Metallized ceramics have more metal coatings than ordinary ceramics, so their electrical conductivity becomes excellent and they can be better used in the electrical field.

Corrosion resistance

Ceramic materials generally have excellent corrosion resistance and can work stably in harsh and corrosive environments.

Wear resistance

The metal coating on the surface of metallized ceramics improves the wear resistance, giving it a better service life in friction, wear and other environments.

High temperature stability

Metallized ceramics tend to be stable at high temperatures and are suitable for applications in high temperature environments.

Ceramic Surface Metallization Process

Metallized ceramics usually have a layer of metal plated on the ceramic surface to enhance the ceramic’s electrical conductivity, corrosion resistance and other characteristics. The following processes are commonly used for metallization of ceramic surfaces:

Metallized Ceramic mechanical properties

| Name | Metallized ceramics | |||

| Density | g/cm³ | 3.5 - 3.9 | Depends on the ceramic matrix and metallization layer composition | |

| Porosity | % | <0.5 | Low porosity enhances mechanical strength and electrical properties | |

| Thermal Conductivity | W/m·K | 15 - 25 | Metallization layer improves thermal conductivity | |

| Thermal Expansion Coefficient | x10⁻⁶/K | 6 - 8 | Matches with metal layer to reduce thermal stress | |

| Flexural Strength | MPa | 300 - 400 | High strength of the base material | |

| Hardness | GPa | 13 - 17 | High hardness, wear-resistant | |

| Fracture Toughness (K_IC) | MPa·m^0.5 | 3 - 4 | Good crack resistance | |

| Electrical Resistivity | Ω·cm | 10⁴ - 10⁸ | Metallization layer provides lower resistivity | |

| Dielectric Constant | – | 9 - 10 | Suitable for high-frequency applications | |

| Dielectric Strength | kV/mm | 10-15 | High dielectric strength ensures electrical insulation properties | |

Metallized Ceramics Processed In Class 10,000 Clean Room

We focus on the manufacturing and sales of various engineering ceramic products, including alumina ceramics, boron nitride ceramics, silicon nitride ceramics, etc. In order to meet the needs of customers, we specially built a 10,000-level clean room to allow metallized ceramics to be used in Processed in a class 10,000 dust-free environment to make its adhesion and permeability stronger.

Metallized ceramics have begun to occupy an increasing share in modern industry and can have both the properties of metal and ceramics. However, during the processing process, it is greatly affected by the external environment, such as the impact of dust on adhesion and some chemical bonding effects. It is a ceramic processing technology with a relatively high technical content. We have mastered this technology and specially created a 10,000-level dust-free environment. Therefore, you place an order directly and we are responsible for delivery!

Current Applications of Metallized Ceramic Technology

Energy

Metallized ceramics are used in fuel cells, solar cells, battery separators, etc. Their superior conductivity and corrosion resistance can improve the performance and stability of energy equipment, so they are widely used in the energy field.

Electronic Equipment

Metallized ceramics are mainly made into integrated circuits (ICs), electronic connectors, resistors, capacitors, etc. in the electrical field. Its excellent electrical conductivity and corrosion resistance make it one of the important materials in electronic devices.

Aerospace

Metallized ceramics are resistant to high temperatures, corrosion, and wear, which make them widely used in the aerospace field. They are often used to manufacture aerospace engine parts, missile casings, spacecraft casings, etc.

Automotive

In the field of automobile manufacturing, metallized ceramics are often used in the manufacture of engine parts, exhaust systems, braking systems, etc., and have very important application value.

Medical

The biocompatibility and corrosion resistance of metallized ceramics make them ideal materials for the manufacture of medical devices, such as artificial joints, dental implants, surgical instruments, etc.

One-Stop Metallized Ceramic Fabrication Services

15+ Years of Experience. High Precision and OEM Design. Professional R&D Team. Competitive Price.

What is the principle of ceramic metallization?

Ceramic metallization is to coat a layer of metal on the surface of ceramics to give the ceramics better properties and uses, and expand the application fields of ceramics.

Can metallized ceramics be customized?

Metallized ceramics can be customized. Our professional team can provide you with, but not limited to: technical support and advice, transparent communication on the customization process, quality assurance and after-sales service, etc., to meet your customization needs.

What is the difference between metallized ceramics and ordinary ceramics?

Metallized ceramics are coated with a metal coating on the surface of ordinary ceramics. Metallized ceramics have better electrical conductivity and other enhanced properties than ordinary ceramics, so additional metal coating materials and processes are required during the preparation process.

What is the environmental performance of metallized ceramics?

Metallized ceramics have certain advantages in environmental performance, which mainly depend on the metal coating materials used and the process used in the preparation process.

How do metalized ceramics compare to metals?

Compared with pure metals, metallized ceramics generally have lower densities, giving them an advantage in applications where lightweighting is required.