Ceramic Brazing vs. Ceramic Metal Brazing: A Comprehensive Guide

Introduction

Joining ceramics or ceramics with metals presents unique challenges. Ceramic brazing and ceramic metal brazing offer powerful solutions for creating permanent, high-performance bonds. This guide explores the key differences between these techniques, helping you make an informed decision for your project.

Ceramic Brazing: Joining Ceramics and Glass

Function: Creates strong, permanent bonds between various ceramic or glass pieces.

Applications:

- High-voltage electrical insulators

- Fluid flow components

- Scientific instrumentation

Process:

- Preparation: Thorough cleaning and surface preparation of ceramics/glass for optimal bonding.

- Brazing Filler Metal Application: Molten metal filler wicks into the joint, solidifying upon cooling to form a strong bond.

- Filler Metal Selection: Depends on ceramic type, desired joint strength, and application requirements (e.g., silver-copper alloys, nickel-based alloys).

Ceramic Metal Brazing: Joining Ceramics to Metals

Function: Creates permanent bonds between ceramic and metal components.

Applications:

- High-performance seals in vacuum chambers and high-voltage environments

- Medical equipment (X-ray)

- Aerospace components (sensors)

- Optoelectronics and power tubes

- Lasers

- Rechargeable batteries

- Electronic communication components (feedthroughs)

Process:

- Metallization: Applying a thin metallic layer (often molybdenum-manganese paste with subsequent sintering) to the ceramic surface for improved adhesion.

- Brazing: Joining the metallized ceramic with the metal component using a brazing filler metal melted at high temperatures.

Understanding Brazing Terminology

- Brazing: A metal-joining process that uses a filler metal with a melting point lower than the base metals being joined. The molten filler metal flows into the joint by capillary action, creating a strong bond upon cooling.

- Brazing Metal (also Brazing Filler Metal): The metal used to create the joint between the base metals. It melts at a lower temperature than the base metals and flows into the joint, creating a strong bond upon solidification. Common brazing metals include silver-copper alloys, nickel-based alloys, and active metals.

- Active Metals: Brazing metals containing elements like titanium, zirconium, or chromium that can directly bond to certain ceramic materials without the need for separate metallization.

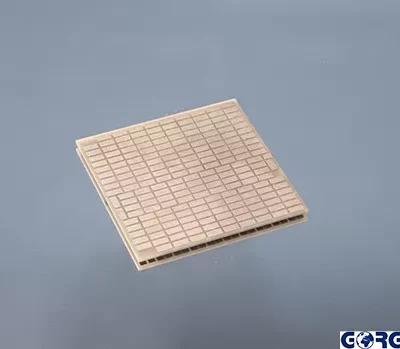

- Metallized Ceramics: Ceramics that have a thin metallic layer applied to their surface. This layer improves adhesion between the ceramic and the brazing filler metal during ceramic metal brazing.

- Ceramic Metallization: The process of applying a thin metallic layer to the surface of a ceramic. This is typically done to improve adhesion for ceramic metal brazing.

How to Braze Metal (General Process)

While the specifics may vary depending on the materials and brazing technique, here’s a general overview of how to braze metal:

- Clean and prepare the metal surfaces: This ensures a strong bond by removing dirt, oxides, and other contaminants.

- Assemble the parts: Secure the metal pieces in the desired position for brazing.

- Apply flux (optional): Flux can help improve brazing flow and prevent oxidation.

- Apply brazing filler metal: Place the brazing metal near the joint.

- Heat the joint: Use a torch or other heat source to melt the brazing filler metal and flow it into the joint.

- Allow the joint to cool: The brazing filler metal will solidify, creating a strong bond between the metals.

Is Ceramic a Metal?

No, ceramic is not a metal. Ceramics are typically inorganic, non-metallic materials known for their high strength, hardness, and heat resistance. Metals, on the other hand, are generally good conductors of heat and electricity, and are malleable (can be hammered into shape) and ductile (can be drawn into wires).

Metal Ceramic vs. Ceramic Metal

- Metal Ceramic: This term is less common and can sometimes refer to a composite material where a thin layer of ceramic is applied to a metal substrate. It can also refer to a type of dental crown where a metal base is covered with a ceramic layer.

- Ceramic Metal: This refers specifically to joining ceramic and metal

Summary Comparison Table

Feature Ceramic Brazing Ceramic Metal Brazing Purpose Joins ceramics or glass Joins ceramic to metal Materials to be joined Any two ceramics, ceramic and glass Ceramic and metal Metalization Not always required Required Applications Joining various ceramics or glass for permanent bonds Joining ceramics to metals for high-performance seals Examples Joining alumina to silicon nitride, zirconium oxide to aluminum nitride Joining alumina ceramic to Kovar metal, silicon nitride to Inconel, brazing ceramic to stainless steel Surface Treatment Requires pre-treatment of ceramic surface Choice of metallization method depends on desired properties and compatibility with brazing filler metal Choosing the Right Technique

The most suitable method depends on your project’s specific needs:

- Materials: Ceramic brazing for ceramics/glass, ceramic metal brazing for ceramic-metal joints.

- Joint Strength: Ceramic metal brazing generally offers higher strength.

- Application Requirements: Consider factors like temperature resistance and environmental conditions.

Additional Considerations

- Both ceramic brazing and ceramic metal brazing are often performed in controlled environments like Class 10,000 cleanrooms to minimize contamination and ensure cleanliness, leading to optimal results.

GORGEOUS Offers Expertise in Ceramic and Metal Joining

If you require high-performance bonds for your project, GORGEOUS can help. We offer extensive experience in ceramic and metal joining, including:

- Design and testing of various ceramic-metal combinations to meet your specific needs.

- Manufacturing ceramic metal seals with a wide range of materials and configurations to suit your project requirements.

- Quality control measures like leak detection and X-ray flaw detection to ensure the integrity and performance of your brazed joints.

Conclusion

By understanding ceramic brazing and ceramic metal brazing, you can select the ideal method for your joining needs. Whether you require strong ceramic or ceramic-metal bonds, these techniques offer reliable solutions for diverse applications in various industries.

Call to Action

For any inquiries about ceramic or ceramic-metal joining for your project, or to discuss how GORGEOUS’ expertise can benefit you, contact us today!