Ceramic Brazing: Achieving Peak Performance with Flawless Metal-Ceramic Integration

Introduction

- Ceramic brazing represents a breakthrough in material science, seamlessly fusing the unique properties of metals and ceramics. This innovative technique overcomes the limitations of single materials, creating high-performance metal-ceramic structures. Across diverse industries like aerospace, electronics, medicine, and automotive, ceramic brazing shines with its exceptional strength, thermal conductivity, corrosion resistance, and high-vacuum compatibility.

The Science Behind Ceramic Brazing

Ceramic brazing utilizes brazing filler metals to create a permanent and robust bond between ceramics and metals under controlled vacuum or inert gas environments. The molten brazing metal wets and adheres to both surfaces, forming a strong and reliable joint.

Advantages of Ceramic Brazing

Airtight Integrity: Brazed metal joints offer exceptional gas-tight seals, preventing leaks even in vacuums, ensuring equipment stability and safety.

- Superior Electrical Insulation: Ceramic metallization boasts outstanding electrical insulation properties, making it ideal for high-voltage components and a core element in high-voltage smart power equipment.

Unmatched Thermal Management: Metal-ceramic components excel in thermal conductivity and maintain dimensional stability under extreme temperatures. This translates to efficient and stable heat dissipation in electronic equipment.

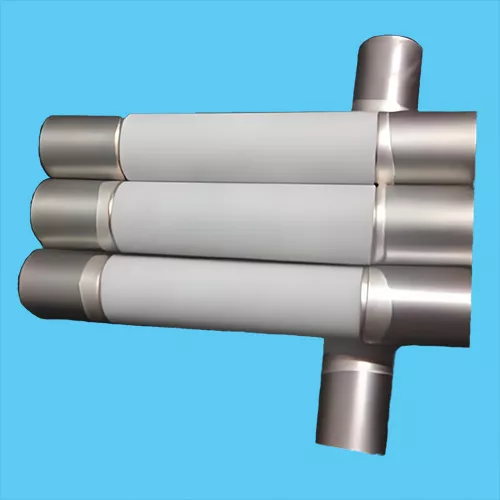

- ceramic-metal connectors

Beyond the Benefits: Addressing Challenges in Ceramic Brazing

While ceramic brazing offers undeniable advantages, it also presents some challenges. Here’s how we address these complexities:

- Design and Material Complexity: We meticulously categorize and analyze various materials involved in the process, outlining their properties and leveraging practical experience to achieve a deeper understanding of material behavior and application.

- Time Constraints: Advanced and intelligent manufacturing equipment allows us to optimize production efficiency and minimize delivery times.

- Stringent Quality Control: To meet the most rigorous quality standards, we conduct a comprehensive battery of tests, including fatigue analysis, leak testing, and insulation withstand voltage testing. Our testing standards exceed actual use requirements by 1.5 times.

- Universal Compatibility: Standard products strictly adhere to international standards, while customized solutions surpass these standards for enhanced compatibility.

Metal Ceramic Brazing: Addressing Specific Challenges

- Material Limitations: We meticulously adjust material ratios to ensure ceramics maintain their integrity during brazing, minimizing the risk of cracking.

- Precise Process Control: In vacuum, dust-free, or specific gas environments, we meticulously regulate temperature and atmosphere to optimize brazing success rates.

Overcoming Quality Inspection Hurdles: We leverage advanced techniques like joint design and finite element analysis (FEA) to predict and prevent joint failures before production. Additionally, we utilize X-ray flaw detection and 3D imaging equipment to identify and eliminate defects in brazed joints, minimizing human error.

Our Commitment to Your Needs

With a thorough understanding of the potential challenges, we stand ready to provide solutions tailored to your specific requirements. Feel free to contact us and explore how ceramic brazing can elevate your project.

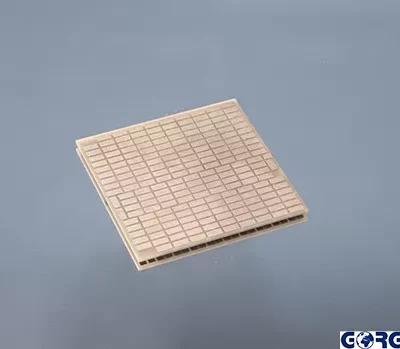

Ceramic Brazing Materials

Customized Materials (reference only, actual specifications may vary):

- Process Services and Prototype Development:

- Stress and reliability analysis

- Fixture design, modeling, and simulation

- Defect analysis

- Ion cleaning, ceramic metallization, and vacuum brazing

Brazemetals and Ceramic Materials:

- Ceramics:

- Aluminum Nitride (AlN)

- Beryllium Oxide (BeO)

- Silicon Nitride (Si3N4)

- Silicon Carbide (SiC)

- Aluminum Silicon Nitride (AlSiN)

- Boron Nitride (BN)

- Zirconium Oxide (ZrO2)

- Yttrium Aluminum Garnet (YAG)

- Polycrystalline Alumina (Al2O3) (purity: 95% - 99.7%)

- Other ceramics: Graphite, Ruby (Al2O3 - 100% purity), Sapphire (Al2O3 - 100% purity)

- Metals and Alloys:

- Gold (Au) - minimum purity 99.9%

- Common alloys: K gold, Dental gold, Conductive gold

- Silver (Ag) - minimum purity 99.9%

- Common alloys: Solder silver, Electrical silver, Medical silver

- Copper (Cu) - minimum purity 99.9%

- Common alloys: Bronze, Brass, Cupronickel

- Other Metals/Alloys: Nickel ((Ni), Palladium (Pd), Platinum (Pt) * Brazing/Welding Metals/Alloys: * Molybdenum (Mo) * Niobium (Nb) * Kovar (Ni-Cr-Fe alloy) * Invar (Ni-Fe alloy)

- Gold (Au) - minimum purity 99.9%

- Inconel (Ni-Cr alloy)

- Hastelloy (Ni-Mo-Cr alloy)

- Superalloy (Ni-based alloy)

- Fe (Ni-Fe alloy)

- 300(304/316) series stainless steel (austenitic)

- Nickel-titanium alloy

- Other alloys: Cobalt-chromium, Tungsten-chromium-cobalt, Titanium-aluminum, etc.

Brazing Process

Depending on the specific materials and customized parts, we utilize either vacuum sealing or hydrogen protection welding for brazing metal and ceramic metallization. Silver-copper solder is a common choice, with a typical operating temperature reaching 800°C. Higher temperature brazing can be employed upon request (e.g., gold-copper solder reaching 1000°C).

Performance Characteristics

- Airtightness: Up to 1×10-10atm cc/sec He

- Strength: Up to 120MPa

- Insulation Resistance: Typically exceeds 1 GΩ @ 100 VDC

Conclusion

Ceramic brazing offers unparalleled freedom to combine various ceramics and metals, creating novel metal-ceramic structures with exceptional properties. Through mature brazing and ceramic metallization processes, we break the limitations of single materials, enabling the creation of diverse and highly customizable brazed joints.