Ceramic Shaft

Custom Ceramic Shaft Supplier,Ceramic shafts Manufacturer ;Factory direct supply;Extended use by more than 10%!

Orders now! 10% Discount!

Custom Ceramic Shaft Supplier

Gorgeous Advantage

Ceramic Shaft Description

Ceramic shafts are essential components for various pump applications, and their application range is wide, including various water pumps and motor equipment.

Ceramic materials have excellent wear resistance and can withstand long-term friction and impact. Compared with traditional metal shafts, ceramic shafts are more durable and are an economical choice for you to save costs!

Ceramic Shafts of Different Materials

A variety of materials are available for customization

GORGEOUS has extensive experience in manufacturing ceramic shafts made of materials such as alumina, zirconium oxide, and silicon nitride.

Alumina Ceramic Shafts

Alumina ceramic shafts have high hardness, wear resistance and insulation properties, and are suitable for precision equipment and harsh working conditions.Inquire now and get a quote!

Zirconia Ceramic Shafts

Zirconia ceramic shafts have high strength, high toughness and wear resistance, and are suitable for high precision and high load applications.Inquire now and get a quote!

Silicon Nitride Shaft

Silicon nitride ceramic shafts combine lightweight, high strength and high temperature resistance, and are widely used in high-speed and high-temperature environments.Inquire now and get a quote!

Main Properties of Ceramic Shafts

High Hardness

Ceramic materials are harder than traditional metals

Wear-Resistant

It can withstand greater friction without being easily worn and has a long service life.

Corrosion Resistant

Not easily corroded by chemicals, and resistant to most acids, alkalis, salts, etc.

High Temperature Resistance

It can resist extreme high temperature and is not prone to deformation.

Electrical Insulation

Excellent electrical insulation, can be used in electrical equipment.

GORGEOUS Customizable Product Accuracy Reference

| Shaft Part | Cylindricity can reach 0.003mm |

| Coaxiality can reach 0.002mm | |

| Roughness 0.02 | |

| Minimum Processing Hole Diameter | Up to 0.3mm, depth limit is 3mm |

| Hole depth accuracy can reach 0.005mm | |

| Roughness 0.02~0.04 | |

| Plane Machining Tolerance | Parallelism accuracy can reach 0.002 |

| The measurement tolerance is 0.0015mm | |

| Ceramic Thread Machining | Processing internal thread size limit M3.0 |

| Thread accuracy gb-7h | |

| No restrictions on external thread size | |

| Thread accuracy can reach gb-6g |

*The specific accuracy needs to be determined according to the actual product material, shape and process requirements.

Ceramic shaft standard size and specifications

Diameter Range

Micro shaft: 0.5mm - 3mm (commonly used in micro motors)

Conventional shaft: 3mm-20mm (pumps, valves, bearings, etc)

Large shaft: 20mm-50mm or larger (high temperature furnace drive shaft)

Length Range

Short axis: 5mm-50mm (micro motor or sensor)

Medium-long axis: 50mm-300mm (mechanical field)

Extra-long axis: 300mm-1000mm (special equipment)

Examples of Common Diameters

Small diameter: 1mm, 2mm, 3mm, 5mm, 6mm, 8mm

Medium diameter:10mm、12mm、15mm、20mm

Large diameter:25mm、30mm、40mm、50mm

「Support non-standard customization」

「MOQ 1 piece sample order」

Customized Ceramic Shaft Material Parameters and Selection

Guide to Choosing Various Ceramic Materials!

✔️Alumina: Alumina shaft is the cheapest among many materials, with a very high cost performance. Its density is 3.7-3.92g/cm3 . You can choose 95%, 99%, 99.5%, 99.7% and other purity alumina for customization.

✔️Zirconia: The density of zirconia shaft is relatively large, exceeding 6.0g/cm3. It has stronger fracture performance than other materials, overcomes the brittleness of ceramics, and it is also self-lubricating, which is very suitable for shaft and pump applications. In addition, you can also choose TTZ, YTZP, ZDY, ZTA and other materials.

✔️Silicon nitride: Silicon nitride shafts are more expensive, but they are lighter and can be polished to a mirror finish of Ra0.05um.

✔️Silicon carbide: The density of silicon carbide shafts is similar to that of silicon nitride, and their hardness is higher than that of general ceramic materials, and their wear resistance is also better.

| Item | Unit | Zirconia Ceramic |

| Density | g/cm3 | 6.0 |

| Zirconia Content | % | 94.4 |

| Grain Size | µm | 0.5 |

| Rockwell Hardness(45N) | R45N | 78 |

| Vickers Hardness(Load 500g) | GPa(Kg/mm2 ) | 11.5(1175) |

| Flexural Strength (20℃) | MPa | 800 |

| Compressive Strength (20℃) | MPa | 2000 |

| Fracture Toughness(20℃) | MPam1/2 | 9.0 |

| Thermal Conductivity(20℃-400℃) | W /(m.k) | 2.5 |

| Coefficient of Thermal Expansion | 10-6 /℃ | 9.6 |

| Thermal Shock Resistance | △T℃ | 250 |

| Property | Unit | AL2O3 99.7 | AL2O3 99.5 | AL2O3 99 | AL2O3 95 |

| Purity | — | 99.7% | 99.5% | 99% | 95% |

| Density | g/cm3 | 3.92 | 3.9 | 3.8 | 3.7 |

| Bending Strength | MPa | 375 | 370 | 340 | 304 |

| Compressive Strength | MPa | 2450 | 2300 | 2250 | 1910 |

| Elastic Modulus | GPa | 380 | 370 | 330 | 330 |

| Fracture Toughness | MPam1/2 | 4.5 | 4.3 | 4.2 | 3.8 |

| Hardness | HRA | 91 | 91 | 90 | 89 |

| Vickers Hardness | HV1 | 1600 | 1550 | 1450 | 1400 |

| Thermal Expansion Coefficient | 10- 6 K-1 | 7.8 | 7.8 | 7.7 | 7.5 |

| Thermal Conductivity | W/mk | 32 | 32 | 25 | 25 |

| Thermal Shock Stability | △T.℃ | 220 | 220 | 200 | 200 |

| Maximum Operating Temperature | ℃ | 1750 | 1750 | 1700 | 1500 |

| Volume resistance at 20℃ | Ω·cm | 1015 | 1015 | 1014 | 1014 |

| Dielectric Strength | KV/mm | 22 | 20 | 16 | 15 |

| Dielectric Constant (room temperature) | / | 10 | 11 | 11.5 | 11 |

| MHz Dielectric Loss Factor | tan δ | 1×10-3 | 1×10-3 | 3×10-3 | 3×10-3 |

Customizable Ceramic Shaft end Type Reference

🔷Straight: can be directly mounted to bearings, bearing seats, brackets, etc.

🔷Keyed: can be precisely combined with your machine to transmit torque to gears, sprockets, etc.

🔷D-Profile: one end is flat and allows insertion into the shaft to firmly install gears, sprockets and bearings, etc.

🔷Splined: can be customized with multiple keyway-like grooves, which can be used in hydraulic systems and machine tools.

🔷With Retaining Ring Grooves: can clamp the retaining ring into the groove, which can be used to separate and locate bearings, rings and sprockets.

🔷Step Down: can use the shoulder near the end of the shaft as a shaft support.

🔷Threaded: the end of the shaft is threaded and can be linked to threaded accessories.

🔷Tapped: has threads inside and can be installed on threaded posts.

🔷Hollow: lighter than solid shafts, can reduce the overall weight of the equipment, can be used for wires, compressed air pipes, etc.

Application of Ceramic Shaft

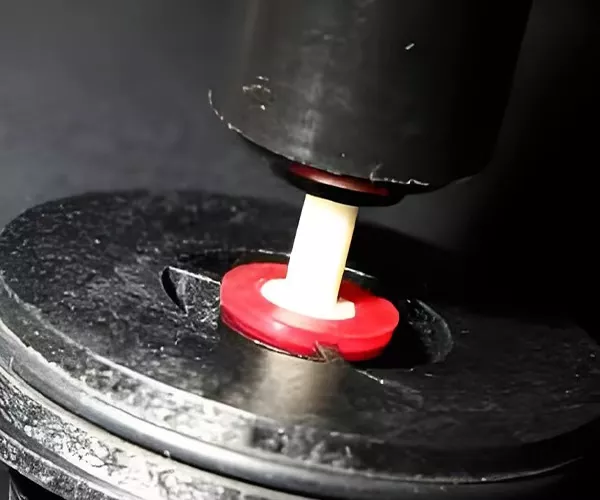

Pump Equipment

Ceramic shafts are corrosion-resistant and rust-free, suitable for media environments such as acid and alkali solutions, seawater, and pure water. They can be used in water pumps, chemical pumps, metering pumps, peristaltic pumps, ceramic impeller shafts, etc. They are not prone to wear during long-term operation and extend the service life of the pump.

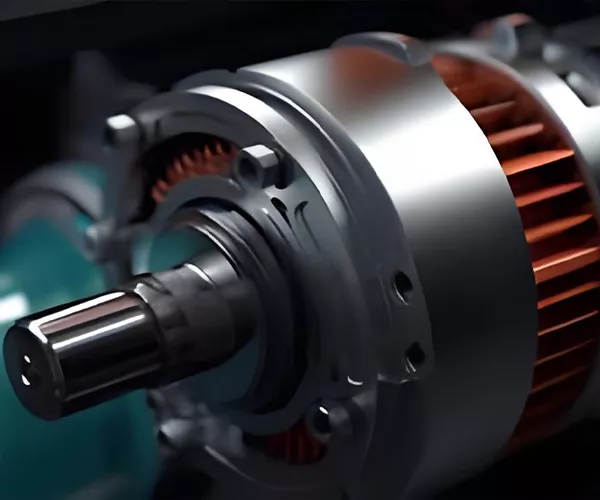

Electric Motors

Ceramic shafts are lightweight and reduce moment of inertia, contributing to energy savings and efficient operation. Their excellent insulation properties prevent electrical corrosion on metal motor shafts caused by current leakage, making them commonly used in small motors, stepper motors, and brushless dc motors

Home Appliances

In aquarium equipment (such as fish tank pumps, filters, and ceramic impeller shafts), ceramic shafts are quiet, free of magnetic interference, and corrosion-resistant. In small household appliances (such as soymilk makers, juicers, water purifiers, and air conditioning compressors), ceramic shafts can reduce noise and wear, improving durability.

Medical Devices

Ceramic shafts are used in medical pumps and testing equipment because of their good biocompatibility and strong chemical resistance to avoid contamination.

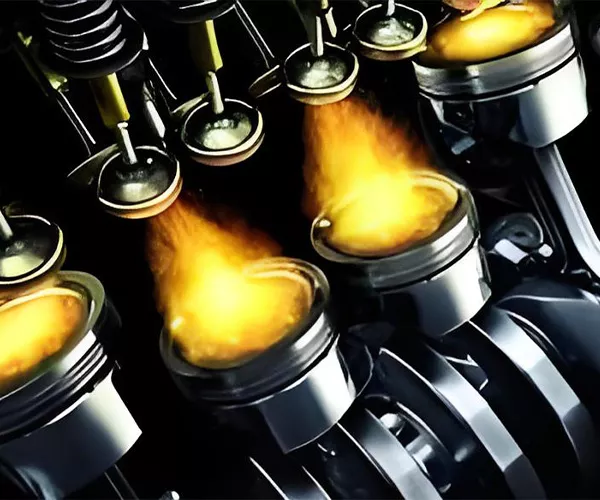

Cars and Transportation

Ceramic shafts can be used in fuel pump shafts, turbocharger components, hybrid and electric vehicle motor shafts, etc. The ceramic material can significantly improve high temperature resistance and friction, and enhance reliability.

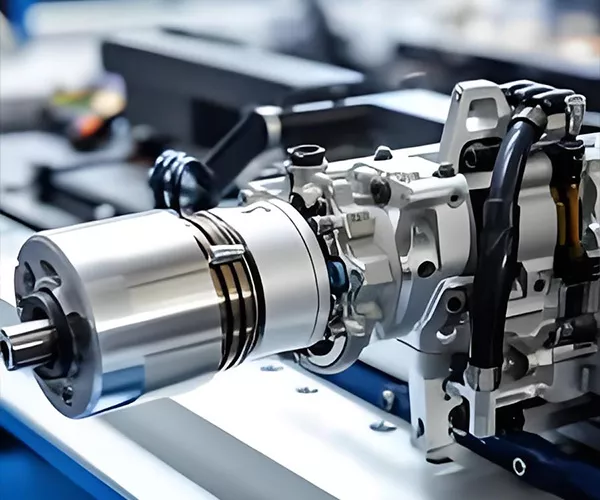

Industrial Machinery

Ceramic shafts operate stably in highly clean and high-temperature environments, and can avoid metal corrosion caused by magnetic fields and chemical media. They can be used in precision machinery, semiconductor equipment, textile machinery, magnetic pumps, and vacuum equipment.

One-stop ceramic shaft manufacturing service

Our ceramic shafts offer a minimum order quantity (MOQ) of one piece to accommodate small order needs. Experience our service today.

Why Choose GORGEOUS?

At GORGEOUS, quality control is our top priority. Every ceramic shaft is manufactured to our customers’ exacting specifications and undergoes extensive inspection and testing, from raw materials to finished product, to ensure consistent performance and reliable quality.

Our factory is certified to IATF 16949:2016 for the automotive industry and ISO 9001:2015 for international quality management systems. This not only demonstrates our commitment to quality, but also ensures we can provide our customers with high-standard customized solutions.

Ceramic Shaft vs. Metal Shaft

Ceramic shafts have excellent wear resistance and corrosion resistance, especially in some high temperature and corrosive environments.

Metal shafts have better impact and vibration resistance, but are easily corroded and worn.

Ceramic Shaft Manufacturing Process

- Raw material preparation: Select and process suitable ceramic raw materials.

- Molding: Dry pressing, injection molding, etc.

- Drying: Remove moisture after molding and wait for sintering.

- Sintering: High temperature sintering to form a hard ceramic structure.

- Post-processing: Precision machining or other processing.

How to Customize Poducts?

You only need to send us an inquiry and drawings, and our professional team will customize it for you.