Boron Nitride Ceramic

Boron nitride ceramic can be sintered from the raw materials of bn (boron nitride), hexagonal boron nitride, and cubic boron nitride. The boron nitride formula is BN, and the boron nitride structure includes hexagonal boron nitride (HBN), rhombohedral boron nitride (RBN), cubic boron nitride (CBN) and wurtzite boron nitride (WBN).

Can be processed quickly according to your customized selection!

Boron Nitride Ceramic

Gorgeous Advantage

Your Tursted Boron Nitride Ceramic

Boron nitride is a crystal composed of nitrogen atoms and boron atoms, with a molecular formula of BN and a molecular weight of 24.81. The chemical composition is 43.6% boron, 56.4% nitrogen, and the theoretical density is 2.27g/cm3. Boron nitride powder has properties such as looseness, lubrication, light weight, moisture absorption, and white color. Boron nitride products are ivory white. At present, boron nitride is mainly concentrated in its hexagonal phase (H-BN) and cubic phase (C-BN). The main uses of C-BN are: cutting tools, abrasives and abrasives, which can be used for cutting all metals and non-metals, including ferrous metals, and for finishing. The structure and properties of H-BN are similar to graphite, and it is a good high-temperature lubricating material and high-temperature electrical insulation material. Therefore, because of its different structures, boron nitride can be used in different situations and can be formed into different ceramics.

Boron Nitride

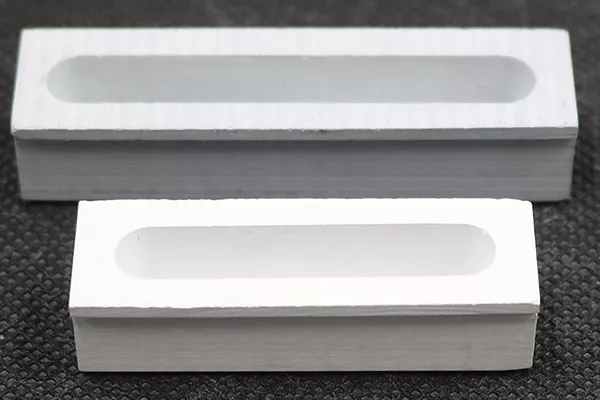

Ceramic Product Display

Gorgeous products

The thermal conductivity of boron nitride ceramics is similar to that of metal, and it is widely used in some applications that require efficient heat dissipation. Boron nitride ceramics are resistant to high temperatures and can work in environments above 2000°C.

Boron nitride ceramics have a layered structure similar to graphite, which highlights its self-slip properties under high temperature and pressure, which can reduce wear to a great extent.

Boron nitride ceramic crucible

Boron nitride conical crucible

Boron nitride small crucible

Features of Boron Nitride Ceramic

Thermal Performance

Boron nitride has excellent thermal stability and can withstand high temperatures without significant decomposition. It retains its structural integrity even at temperatures exceeding 1000°C.

Electrical Properties

It has the advantages of good dielectric strength, low dielectric constant, low loss at high frequency, microwave penetration, good electrical insulation.

Mechanical Properties

It has the advantages of non-abrasive, low wear, dimensional safety, good lubricity, fire resistance and easy processing.

Chemical Properties

It has the advantages of non-toxicity, chemical stability, corrosion resistance, oxidation resistance, low moisture, biological stability and non-stick.

The difference between hexagonal boron nitride(h-BN) and cubic boron nitride(c-BN)

hexagonal boron nitride(h-BN) and cubic boron nitride(c-BN) are both boron nitride, but due to different crystal structures and properties, their applications are very different.

The mechanical strength of hexagonal phase boron nitride is lower than that of cubic phase boron nitride, but both have good heat resistance and corrosion resistance.

Boron nitride ceramic mechanical properties

| Name | Boron nitride | |||

| Characteristic | Hexagonal boron nitride (h-BN) | Cubic phase boron nitride (c-BN) | ||

| Crystal Structure | Hexagonal | Cubic | ||

| Lattice Constant (Å) | a = 2.504, c = 6.657 | a = 3.615 | ||

| Density (g/cm³) | 2.15 | 3.45 | ||

| Hardness (Mohs Hardness) | 1-2 | 9-10 | ||

Boron nitride physical properties

| Name | Boron nitride | |||

| Characteristic | Hexagonal | Cubic | ||

| Thermal Conductivity (W/mK) | 600-700 | 2000-2700 | ||

| Conductivity (S/m) | 10⁻¹⁵ | 10⁻¹⁰ - 10⁻⁸ | ||

| Heat Resistance | Stable at high temperatures, suitable for high-temperature applications | Stable at high temperatures, suitable for high-temperature applications | ||

| Resistance to Chemical Attack | Good resistance to acids and bases | Good resistance to acids and bases | ||

| Mechanical Strength | Low | Very high | ||

| Optical Properties | Transparent, high optical transmittance | Translucent, optical properties similar to diamond | ||

| Applications | Lubricants, insulation materials, ceramic reinforcements | High-temperature/high-pressure tools, abrasives, cutting tools | ||

Our boron nitride ceramics are available for you to choose from

We are equipped with full-process precise monitoring and various online testing instruments for the production of boron nitride ceramic products, such as laser particle size distribution testers, powder comprehensive performance testers, and three-dimensional coordinate testers, to implement the entire process from raw materials, manufacturing processes to precision. Processing and quality control. The company adopts “6S” management, focusing on prevention and continuous improvement, adhering to the goals and management system of “advanced technology, high-quality products, and high-grade services”.

GORGEOUS provides you with high-quality, low-priced boron nitride ceramic products. We produce perfectly customized quality at very attractive prices. We manufacture and process advanced boron nitride ceramics for crucibles or tubes used to melt and transport metals, rocket combustion chamber liners, spacecraft heat shields, corrosion-resistant components for MHD generators, heat sink chassis for semiconductor packaging, and nuclear reactors. Neutron absorption, shielding materials, etc.

If you have a product or project that requires boron nitride ceramics, you’ll find the right solution at Gorgeous. We have the fastest and most precise processing equipment!

Ceramic For Different Industries

Ceramics are widely used across various fields including electronics, chemical industry, mechanical engineering, medical devices, research, and laboratory settings.

Automotive

Ceramics are used in automotive applications such as engine components, bearings, turbochargers, and exhaust gas recirculation (EGR) valves. Their high strength, thermal stability, and wear resistance make them ideal for these demanding applications.

Aerospace

Ceramics are employed in the aerospace industry for components like turbine blades, combustor liners, heat shields, and bearings. Their lightweight nature, high-temperature resistance, and excellent mechanical properties contribute to improved performance and fuel efficiency.

Electronic Devices

Ceramics are utilized in the electronics industry for applications such as substrates, insulators, and packages. Their excellent electrical insulation properties, high thermal conductivity, and chemical stability make them suitable for electronic devices and circuitry.

Energy and Power

Ceramics find applications in the energy and power generation sector, including components for gas turbines, solar cells, heat exchangers, and high-temperature sensors. Their thermal shock resistance, electrical insulation, and chemical stability are advantageous in these energy-related applications.

Cutting Tools and Abrasives

Ceramics are used in the manufacturing of cutting tools and abrasives due to their high hardness, wear resistance, and thermal stability. They are employed in machining, grinding, and cutting operations across various industries.

One-Stop Boron Nitride Ceramic Parts Fabrication Services

15+ Years of Experience. High Precision and OEM Design. Professional R&D Team. Competitive Price.

How does the high thermal conductivity of boron nitride ceramics compare to other ceramics?

The high thermal conductivity of boron nitride ceramics is very outstanding among other ceramic materials, usually in the range of 100-200 W/(m·K), which is very high. Moreover, its layered crystal structure is similar to graphite. This structure allows heat to be quickly conducted in the material, which is an important reason for the high thermal conductivity. Therefore, it can often be seen in applications that strictly require thermal conductivity.

Why is boron nitride ceramic an ideal insulating material?

The resistance of boron nitride ceramics is very high, usually between 10^13 and 10^16 Ω·cm. At the same time, the dielectric constant is usually low, and the dielectric loss is also small, which is also one of its advantages. The high withstand voltage allows It is not easily broken down by voltage and can ensure signal transmission of high-frequency and microwave electronic devices, making it an ideal insulating material for many electrical equipment and electronic devices.

What is the thermal shock stability of boron nitride ceramics?

The melting point of boron nitride ceramic is very high, reaching more than 3,000°C, and it has excellent thermal shock stability and will not produce cracks even if the temperature changes drastically. The relatively low thermal expansion coefficient ensures that the volume does not change greatly during the heating process. At the same time, boron nitride ceramics are very good at resisting oxidation corrosion at high temperatures due to the adhesion of the oxide film. These characteristics make it an ideal choice for many high-temperature applications.