Porous Ceramic

Porous ceramics are ceramic materials with an open pore structure. They are formed by controlling the composition and processing of the material during preparation, resulting in structures with micro- and macropores.

Advanced technology! Large quantity and excellent price!

Porous Ceramic

Gorgeous Advantage

Your Porous Ceramic Supplier

Porous ceramic pores can vary in shape, size, and distribution, imparting unique properties and applications.

Gorgeous is your trusted porous ceramic supplier in China. We make perfect custom parts with attractive prices. They are perfect for filtration industry, adsorption industry, thermal insulation, acoustic, biomedicine and catalysis industry.

If you have business or projects that need porous ceramic, you will find the perfect products with Gorgeous. We’ve got the most convenient and multipurpose units!

Porous

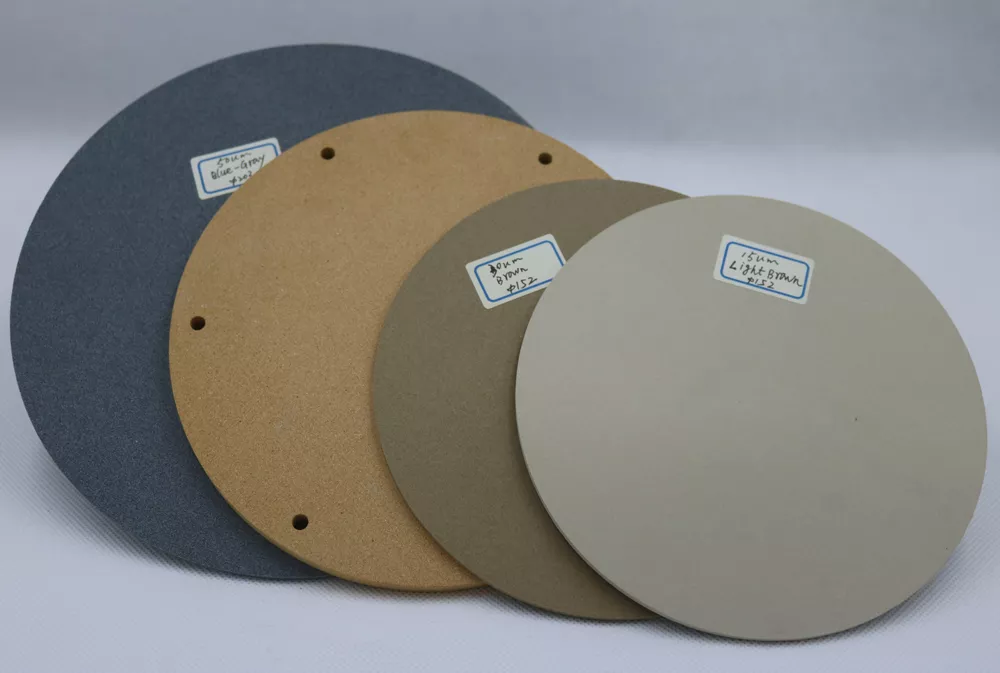

Ceramic Product Display

Latest Products at Feedthrough

The feedthrough adopts ceramic-metal brazing process. The ceramic is made of composite ceramic with more reliable performance, and is brazed with precious metal solder containing gold, nickel, palladium and other ductility. The tightness temperature can exceed 550℃. The air tightness of the ceramic feedthrough reaches 1.5*10-10Pam3/s. The leakage rate of 500℃/10 hours is within the safe range.

Feedthrough/Brazing Ceramic To Metal

Feedthrough/Ceramic to Metal

Feedthrough/Solid sealing technology

Features of Porous Ceramic

Porosity

Porous ceramics possess open pore structures, which provide void spaces within the material. The porosity can be controlled and tailored to meet specific requirements, ranging from low to high porosity levels.

High Surface Area

The presence of interconnected pores in porous ceramics results in a larger surface area compared to solid materials. This increased surface area enhances the material's interaction with gases, liquids, and other substances.

Selective permeability

Porous ceramics can exhibit selective permeability, allowing the passage of certain substances while restricting others based on the size, shape of the pores, enables precise control over the filtration and diffusion processes.

Thermal Insolation

The presence of air-filled voids within the porous ceramic structure contributes to its thermal insulation properties. These trapped air pockets impede heat transfer, making porous ceramics effective insulators.

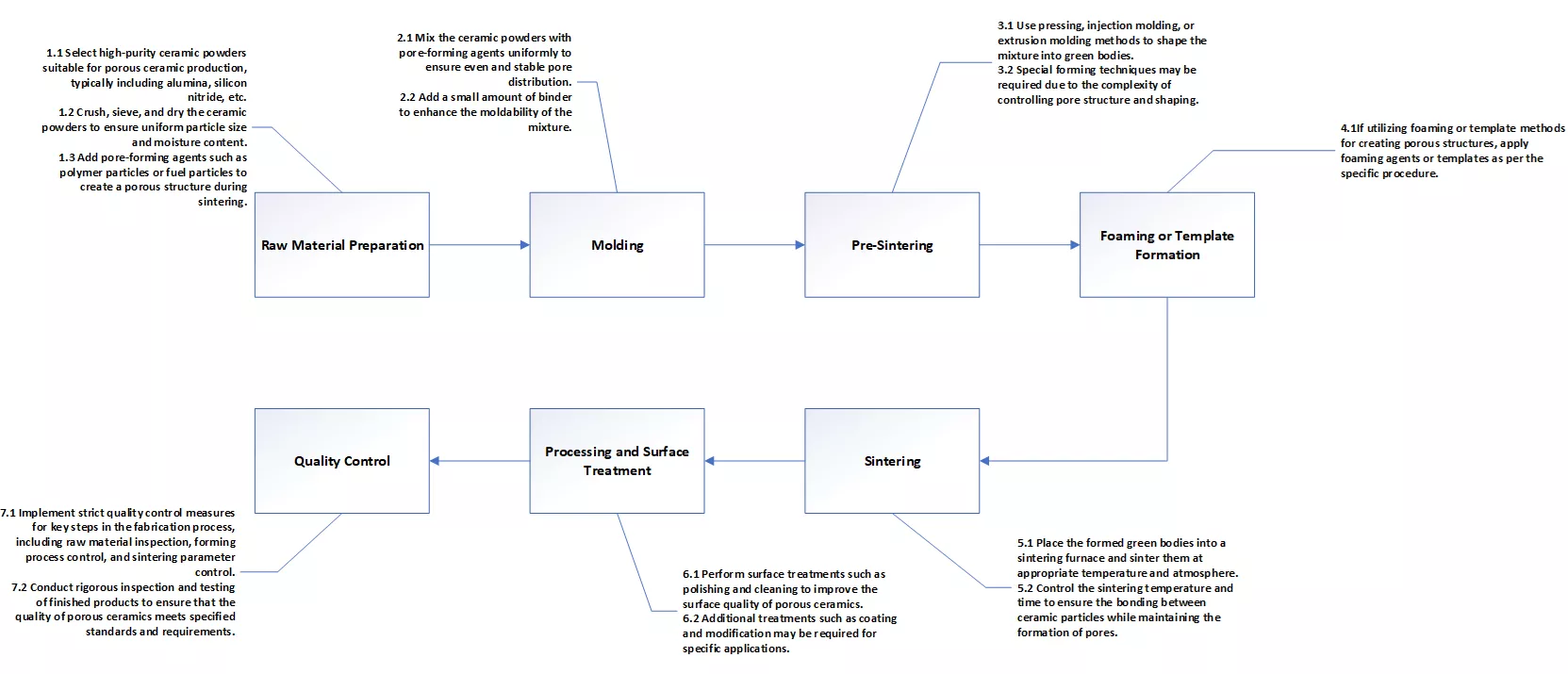

Pore Formation Methods

Porous ceramics are characterized by their porosity, and the morphology of the pores can vary greatly. The diverse methods of pore formation have contributed to the creation of porous ceramics with different shapes and enhanced functionality. The following is a brief description of several common pore formation methods and their characteristics.

Microporous ceramic physical properties

| Name | microporous ceramics | |||

| Young’s modulus (E) | GPa | 10 - 200 | The Young’s modulus of microporous ceramics is relatively low, indicating that it has poor elasticity and is easily deformed. | |

| Poisson’s ratio (ν) | – | 0.1 - 0.3 | The Poisson’s ratio of microporous ceramics is generally low, indicating less lateral deformation during compression. | |

| Compressive strength | MPa | 50 - 500 | Microporous ceramics break easily under high pressure, but their strength depends on their microporous structure and density. | |

| Bending strength | MPa | 10 - 200 | The microporous structure makes the material prone to breakage when bent. | |

| Fracture toughness (K_IC) | MPa·m^0.5 | 1 - 3 | Lower fracture toughness means that microporous ceramics are more susceptible to crack propagation and fracture under stress concentrations. | |

Physical properties of microporous ceramics

| Name | microporous ceramics | |||

| density | g/cm³ | 0.5 - 3 | The density range is wide and is mainly affected by the porosity and matrix material of microporous ceramics. | |

| Porosity | % | 10% - 90% | Porosity determines many physical properties of a material, such as air permeability and mechanical strength. | |

| Thermal conductivity | W/m·K | 0.1 - 10 | Low thermal conductivity is an important characteristic of microporous ceramics in the field of thermal insulation. | |

| Thermal expansion coefficient | x10⁻⁶/K | 1 - 10 | The low coefficient of thermal expansion allows microporous ceramics to remain dimensionally stable in temperature-changing environments. | |

| Specific heat capacity | J/g·K | 0.5 - 1.0 | A lower specific heat capacity means that microporous ceramics change temperature more quickly when they absorb or release heat. | |

| Breathability | m³/m²·h·Pa | Adjustable range | It can be adjusted by controlling the micropore structure and is widely used in filtration and gas separation. | |

| chemical stability | – | high | Microporous ceramics generally have high chemical stability and are suitable for use in harsh chemical environments. | |

产品介绍

We focus on the manufacturing and sales of various engineering ceramic products, including alumina ceramics, boron nitride ceramics, silicon nitride ceramics, and more, which are widely applied in industries such as machinery, chemical, aerospace, and others.

Our customers are spread across the globe and encompass multiple industries, including machinery manufacturing, electronics and electrical, chemical production, medical instruments, aerospace, and more. We have established close cooperative relationships with numerous domestic and international enterprises and research institutions, working together to drive innovation and application of engineering ceramic technology.

Regarding our products, we always adhere to the principle of quality first and customer foremost. We emphasize technological innovation and team collaboration, dedicating ourselves to providing customers with the highest quality products and services.

Current Applications of Porous Ceramic Technology

Ceramic Industrial Solid Waste Resources

The production of porous ceramics from solid waste resources in the ceramic industry has attracted great attention from ceramic industry practitioners and environmental researchers. By using stainless steel molds or silicon carbide molds for filling, high-strength, high porosity, and low bulk density macroporous ceramic materials were produced in roller kilns at temperatures up to 850°C. These materials can be used for wall sound insulation, sound absorption, thermal insulation, and humidity regulation, as well as solid-liquid separation.

Wastewater Treatment

Porous ceramics, as a new type of material for filtration, separation, and purification, have shown significant effectiveness in industrial wastewater purification.

Sound Insulation and Absorption

Porous ceramics, primarily used as sound-absorbing materials, utilize their diffusion effect to disperse the air pressure caused by sound waves through their porous structure, thereby achieving sound absorption. Additionally, porous ceramics exhibit excellent fire resistance and weather resistance, making them suitable for sound insulation and noise reduction in high-rise buildings, subways, tunnels, and other fire safety demanding places.

Biomedical Materials

Porous ceramics with their porous structure facilitate drug loading and provide long-term support due to their durability. They hold great research value in the field of medical biology. Silicon nitride porous ceramics, which are non-toxic to the human body, have great potential in human bone transplantation and bone tissue scaffolding.

Catalyst Carriers

Porous ceramics possess excellent adsorption capacity and activity, making them ideal materials for catalyst carriers. After coating with catalysts, the reaction fluid passing through the pores of porous ceramics significantly improves conversion rates and utilization, finding widespread applications in automotive exhaust purification. Aluminum oxide porous ceramics, with high porosity and large specific surface area, are commonly used as carriers for placing catalysts, particularly in automotive exhaust purifiers.

One-Stop Porous Ceramic Fabrication Services

15+ Years of Experience. High Precision and OEM Design. Professional R&D Team. Competitive Price.

What are the common porous ceramic materials?

Common porous ceramic materials include but are not limited to: alumina, zirconia, silicon carbide, silicon nitride, etc. You can choose different materials to customize porous ceramics according to your special needs.

Can porous ceramics be customized?

We can customize porous ceramics of various shapes, sizes, pore structures, pore sizes, porosity, and surface properties for you to meet your special requirements in various fields, and our professionals will also recommend related industries for you. Recommendations on the best porous ceramic materials to use, pore size and other characteristics.

Why can porous ceramics be used for adsorption and filtration?

Porous ceramics have the characteristics of various pore structures, large surface area, pore size control and good pore permeability. They are suitable for adsorbing and filtering various gases, liquids, particles or microorganisms. They are widely used in water treatment, air purification, chemical separation, Biomedical and other fields.

What are the acoustic properties of porous ceramics?

The acoustic characteristics of porous ceramics depend on factors such as pore structure, pore size, shape, and density of the material. Most porous ceramics have acoustic impedance. Different pore size and distribution factors affect the acoustic impedance. This results in some porous ceramics having very good sound absorption capabilities. Sound waves are continuously reflected and refracted after entering these pores, which reduces the sound in the process. A lot of energy. Designed and optimized according to different application requirements, porous ceramics have unique potential in acoustic materials, acoustic isolation, noise control, acoustic absorption, etc.