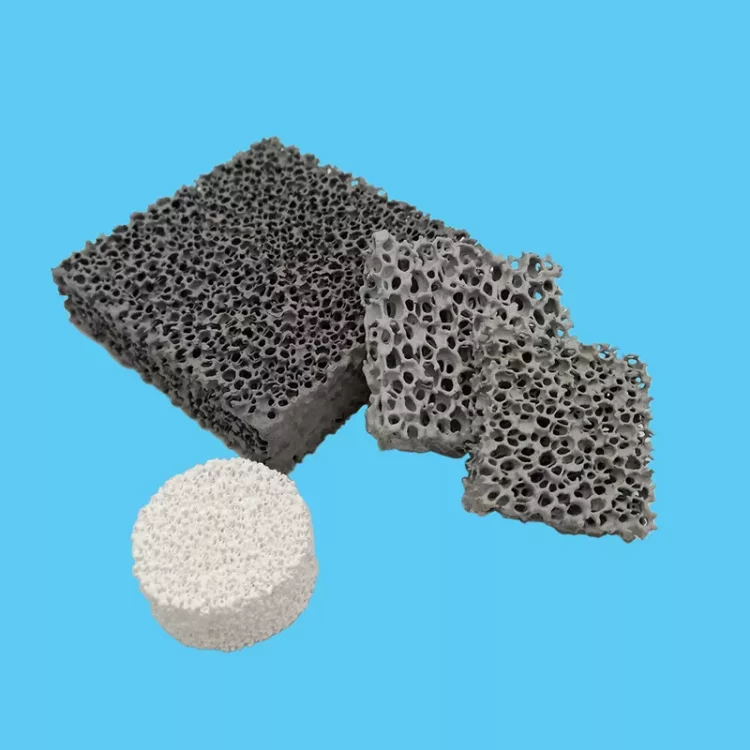

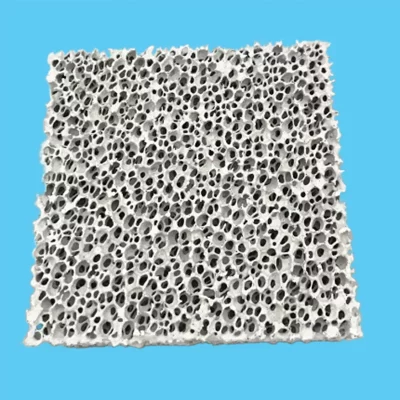

The smoothest and most durable GORGEOUS porous ceramic filter!

GORGEOUS CERAMICS (GGS) Porous Ceramic Filters: More Than Ceramics, It’s Excellence!

Revolutionize Your Filtration Process with GORGEOUS CERAMICS (GGS)!

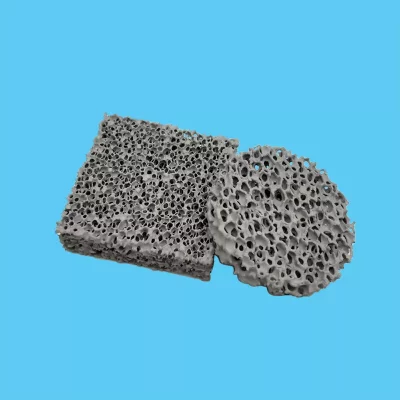

GORGEOUS CERAMICS (GGS) offers premium porous ceramic filters designed to tackle your most demanding filtration challenges in the chemical, petrochemical, and general process industries. We understand the critical role filter media plays in optimizing equipment efficiency and energy consumption. Our high-temperature resistant (up to 850°C) and chemically inert porous ceramic filters ensure smooth operation and improved energy efficiency within your systems.

Unmatched Performance:

- Chemically Inert & High-Temperature Resistant: Handle acidic gases and withstand extreme temperatures (up to 850°C), ideal for harsh environments like chemical plant filtration equipment.

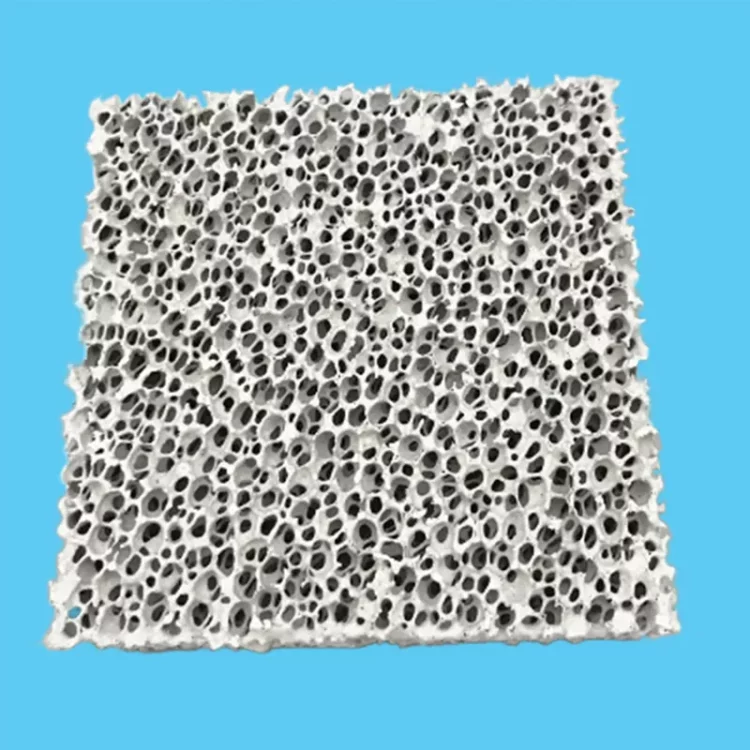

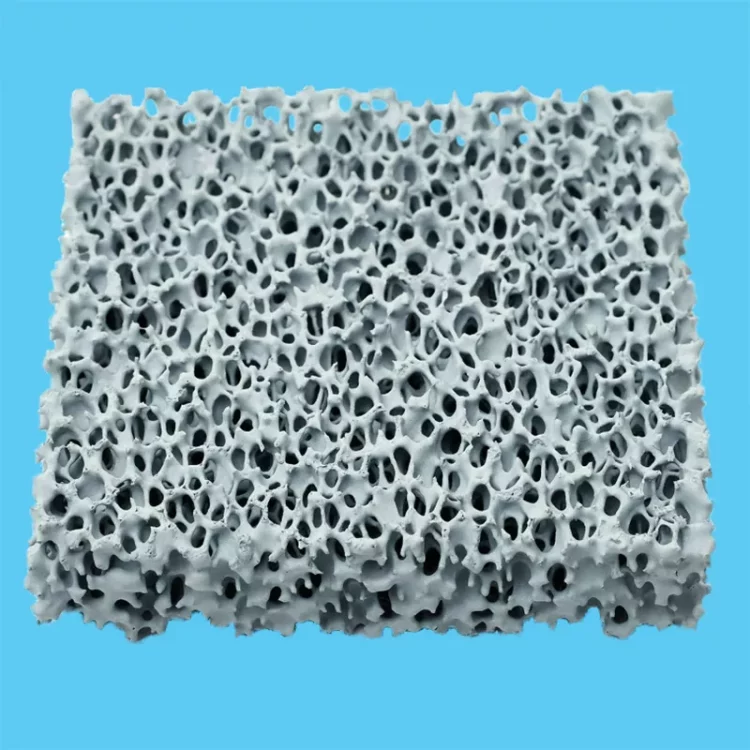

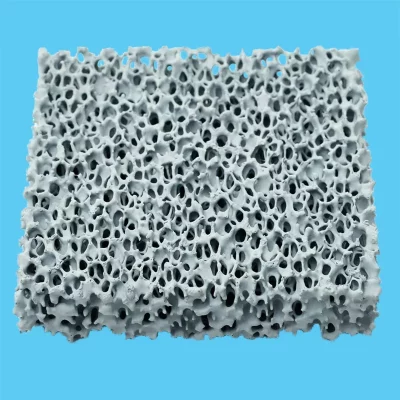

- Customizable Pore Size: Achieve the desired filtration efficiency with a range of pore sizes from 0.3 to 100 microns, along with corresponding filtration meshes to suit your specific fluid needs.

- Powerful Coalescence Ability: Specially treated ceramics effectively remove liquid contaminants like oil and water from air and gas streams, enabling efficient water-gas separation.

- Tailored Solutions: We provide customized production services to seamlessly integrate with existing or custom-built filter housings.

Extensive Applications:

GORGEOUS CERAMICS (GGS) porous ceramic filters’ unique physical and chemical properties unlock a vast array of applications across numerous industries:

1. Hot Gas Filtration in Environmental Protection:

- Application: Filtering high-temperature gases, such as exhaust treatment in industrial furnaces and flue gas purification in coal-fired power plants. In these applications, porous ceramic filters excel due to their high-temperature stability where traditional filter materials fail.

- Example: Ceramic filters function as core components in high-temperature and corrosion-resistant filtration equipment for smoke purification in coal-fired power generation. The flue gas generated during power production reaches temperatures up to 350-1000°C and contains substantial dust and impurities, necessitating efficient filtration.

2. Pre-coated Filter Base Membrane:

- Application: Pre-coated filtration involves applying a specific media layer on the filter surface to enhance filtration performance. Porous ceramic filters, with their porosity and chemical inertness, are ideal substrates for pre-coat filtration.

- Example: In some chemical production processes, raw gas requires deep purification to eliminate minute particles and impurities. Here, a porous ceramic filter serves as a carrier for pre-coat filtration. A layer of high-efficiency adsorption material can be coated on its surface to elevate filtration efficiency and accuracy.

3. Process Filtration:

- Application: Process filtration spans various industrial sectors, including chemical, pharmaceutical, and food industries. These applications require meticulous liquid or gas filtration to remove suspended particles, colloids, and microorganisms.

- Example: Porous ceramic filters are utilized in the pharmaceutical industry for sterile air preparation. By precisely controlling pore size and filtration efficiency, they effectively remove microorganisms and tiny airborne particles, ensuring a clean air environment for pharmaceutical production.

4. Dust and Smoke Filtration:

- Application: Suitable for filtering and treating dust and smoke emitted by various industries, including flue gas purification in cement production, steel smelting, and waste incineration.

5. Compressed Air Filtration:

- Application: Compressed air systems often contain contaminants like oil mist, water mist, and tiny particles that necessitate filtration to ensure compressed air purity. Porous ceramic filters’ high-efficiency filtration and corrosion resistance make them a popular choice in compressed air filtration.

- Example: The machinery manufacturing industry relies heavily on compressed air to power pneumatic tools and equipment. To ensure proper operation and extend the lifespan of pneumatic equipment, compressed air requires strict filtration. Porous ceramic filters effectively remove oil mist, water mist, and tiny particles from compressed air, providing high-quality compressed air for pneumatic equipment.

6. Aquarium Filtration:

- Application: Beyond industrial applications, GORGEOUS CERAMICS (GGS) porous ceramic filters find use in water filtration systems for aquariums and fish tanks. They effectively remove impurities, leftover bait, fish feces, and other organic matter, maintaining clean and transparent water.

Unwavering Quality and Expertise:

GORGEOUS CERAMICS (GGS) porous ceramic filters are crafted from high-grade ceramic materials and undergo rigorous production processes and quality control. This ensures exceptional filtration performance and extended service life for each product.

Competitive Pricing and Delivery:

We offer competitive pricing and flexible delivery schedules based on order quantity and size. For customized products, we engage in detailed communication with customers to ensure on-time delivery.

Unparalleled Customization:

Beyond standard-sized ceramic elements, we provide custom services to meet your specific needs. We can customize size, shape, and filtration efficiency to match your exact requirements.

Please contact us as soon as possible if you need porous ceramic filters!