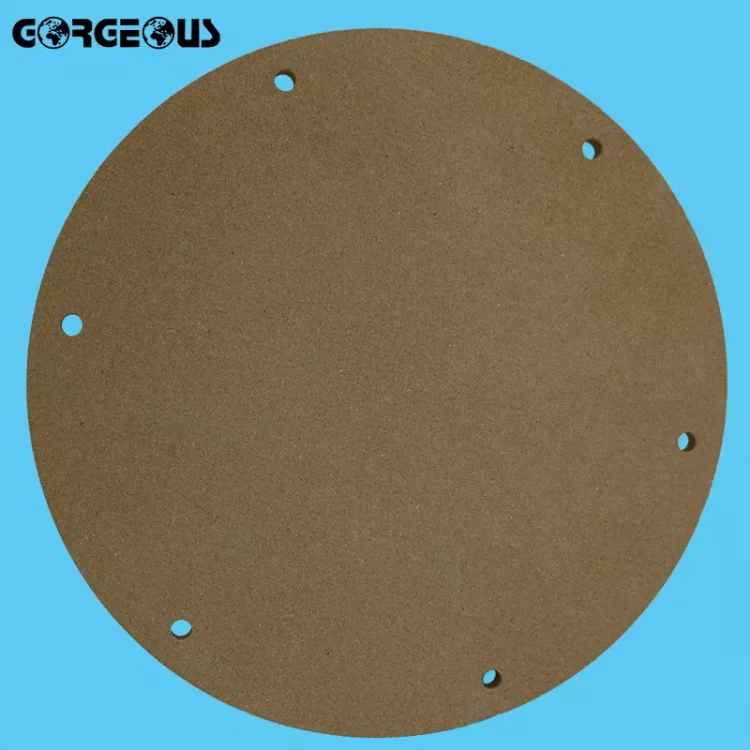

Unbelievable! Processing of extremely tiny 1 microns porous ceramic plates/sheet

[Excellent in ceramics, not limited to ceramics! ]

Porous Ceramic Plate is a ceramic product with uniformly distributed microporous structure, which is commonly used in gas and liquid filtration, purification and separation, chemical catalytic carrier, advanced thermal insulation material, biological implant material, sound absorption and shock absorption, etc. They play an important role in many industrial aviation semiconductor fields with their unique physical surface properties, high temperature resistance, corrosion resistance and high filtration accuracy after processing. This collection page will introduce the classification, characteristics and mutual connection of Porous Alumina Plate, Porous Ceramic Sheets, Porous Vacuum Plate and Porous Ceramic Vacuum Plate in detail, aiming to help you better understand and choose products that suit your needs.In the field of precision ceramic forming and processing, GORGEOUS CERAMICS (GGS) has been innovating in practice. We are constantly innovating and focusing on customization. We provide customized porous ceramic plates to obtain your orders with our price advantage and stable quality.

Product Detailed Feature Description

Porous Alumina Plate

Classification and Characteristics: Porous Alumina Plate is a kind of porous ceramic plate, which is made of alumina as the main raw material and calcined at high temperature. It has high hardness, high wear resistance, excellent chemical stability and thermal stability. Its microporous structure is uniform and has high porosity. It can be used as your catalyst carrier, filter and advanced sound-absorbing and heat-insulating material. Our porous alumina plate can well solve the problem of the vulnerability of traditional materials in high temperature and corrosive environment, and can greatly improve the service life and filtration efficiency of your equipment.

Porous Ceramic Sheets

Classification and characteristics: Porous ceramic sheets are a thin product of porous ceramics with various shapes, including tubular, honeycomb block, plate, etc. The Porous Ceramic Sheets we provide have low density, high strength and good air permeability. They can be used for your fine filtration equipment components for gas and liquid, and can solve the headache problems of low filtration accuracy and easy clogging,

helping you improve filtration efficiency and regenerate and reuse.

Porous Vacuum Plate

Classification and characteristics: Porous vacuum plate combines the advantages of porous ceramic permeability and vacuum technology, and realizes vacuum sealing through microporous structure. It can be used in your vacuum forming, gas shock absorption device and precision instrument manufacturing. Our Porous Vacuum Plate can effectively solve the problem of easy leakage and high cost of traditional vacuum sealing materials, and provide you with a more economical and efficient solution, which can greatly improve the performance of your vacuum equipment and greatly reduce your sealing material cost.

Porous Ceramic Vacuum Plate

Classification and characteristics: Our porous ceramic vacuum plate is the product of the deep integration of porous ceramics and vacuum technology. It not only inherits the high strength, high air permeability and corrosion resistance of porous ceramics, but also has excellent vacuum sealing performance. It is especially suitable for the vacuum sealing in high temperature, high pressure and corrosive environments you need. It can solve the problem of easy failure of vacuum sealing materials in extreme environments and ensure the long-term stable operation of your equipment.

Connection and complementarity

Although the above four products have their own characteristics, they often complement each other in actual applications, and different combinations can meet your complex and changing industrial needs. You can flexibly choose or use these products in combination to achieve the best performance and economic benefits.

[Product Focus]

Our porous ceramic plates, as high-performance ceramic materials in the application of specific cost products, adopt the unique corrosion and dimensional stability of ceramics, and the non-deformation of heat. According to actual needs, we design the pore structure, mesh number, and pore size. Porous ceramic plates can be used in your chemical, environmental protection, metallurgy, energy, medicine, and experiments as key components such as filtration, separation, catalytic carriers, heat exchangers, etc. We hope to give parameters according to your actual situation. We are waiting for your inquiries.

[Product Features]

Pore structure: We can achieve uniform pore distribution, with an error control of 1 microns. The porosity can be adjusted in advance according to the actual rules to meet your precision requirements for filtration, separation, or purification.

High corrosion resistance: We use ceramic materials with a purity of more than 99.5. They all have excellent acid resistance, alkali resistance, salt spray resistance and other corrosion properties of ceramics. In this way, they can be used repeatedly in your actual use, which can improve the service life and save you the cost of the entire life cycle.

High temperature resistance: Ceramics are originally sintered at high temperature, so porous ceramic plates can also be used stably for a long time in high temperature environments, and their pore size will not change greatly due to temperature changes. In this way, they will not be blocked or warped during your use due to hole deformation.

High mechanical strength: Although porous ceramic plates have porous characteristics, they are considered to affect the compression, tensile and bending strength of the plates due to their secondary processing. However, practice has proved that secondary processing has no effect on your normal use in addition to ensuring practical accuracy. On the contrary, it has the possibility of better lightweight operation due to reduced weight.

[Product Advantages]

Tailor-made service: Provide full-process customization services, and drawings can be communicated in advance, including size, flatness, shape, porosity, etc., which can provide you with opinions and suggestions.

Performance: After special membrane processing, porous ceramic plates can make your filtration more efficient and convenient to use.

Cost-effectiveness: Because of the use of high-purity materials, although the initial investment may be higher, based on the durability and reusability of ceramics, the long-term use cost is lower in the whole cycle.

Technical support: Our professional team with 15+ years of experience provides you with full technical support, so that you can have a good transaction cooperation experience in technical support services.

【Product Parameters】

Material: high-quality ceramics (alumina ceramics, aluminum nitride ceramics, silicon nitride ceramics and other materials are optional)

Porosity: can be customized according to your drawings and equipment requirements, ranging from 5%-60%

Working temperature: up to 1250℃

Compressive strength: ≥10MPa

Pore sizes: ranging from 1 to 100 microns

Size: can be customized according to customer needs

Shape: flat plate, disc, special shape, etc.

【Industry reference pictures】

【Contact us】

If you have any questions or needs about the customized service of porous ceramic plates, please feel free to contact us. Our professional team with 15+ experience will provide you with detailed consultation and customized comprehensive solutions.

Inquiry link: https://ggsceramic.com/contact

We hope you will choose GORGEOUS CERAMICS (GGS), choose experience, professionalism, and service. We look forward to your customized order!