Porous Vacuum Chuck is your best assistant and a master at manipulating (adsorbing and holding) precision workpieces

Effortless Adsorption and Holding for Thin Films and More

Struggling with adsorption and holding during the delicate handling of thin films and other flexible workpieces? Look no further than the GORGEOUS CERAMICS (GGS) Porous Vacuum Chuck series - your one-stop solution for unmatched efficiency and precision.

Engineered for Excellence in Key Industries

Our porous vacuum chucks are specifically designed to excel in the electronics, semiconductor, solar energy, medical, and optical laser micromachining industries. These innovative suction cups will revolutionize your production process, granting you:

- Unprecedented Convenience: Experience a new level of ease in handling delicate workpieces.

- Enhanced Efficiency: Streamline your production and achieve faster turnaround times.

- Reduced Failure Rates: Minimize errors and ensure consistent, high-quality results.

Features and Benefits

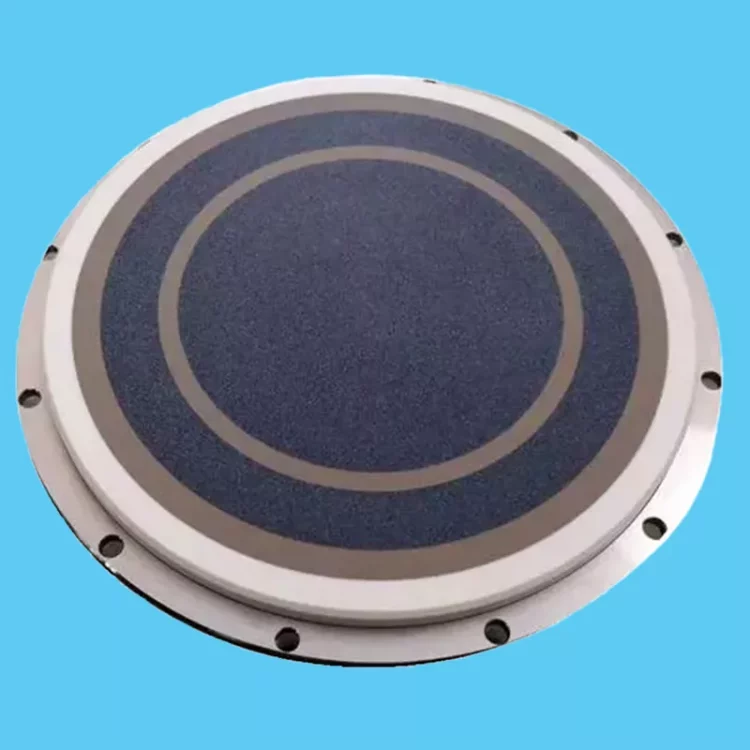

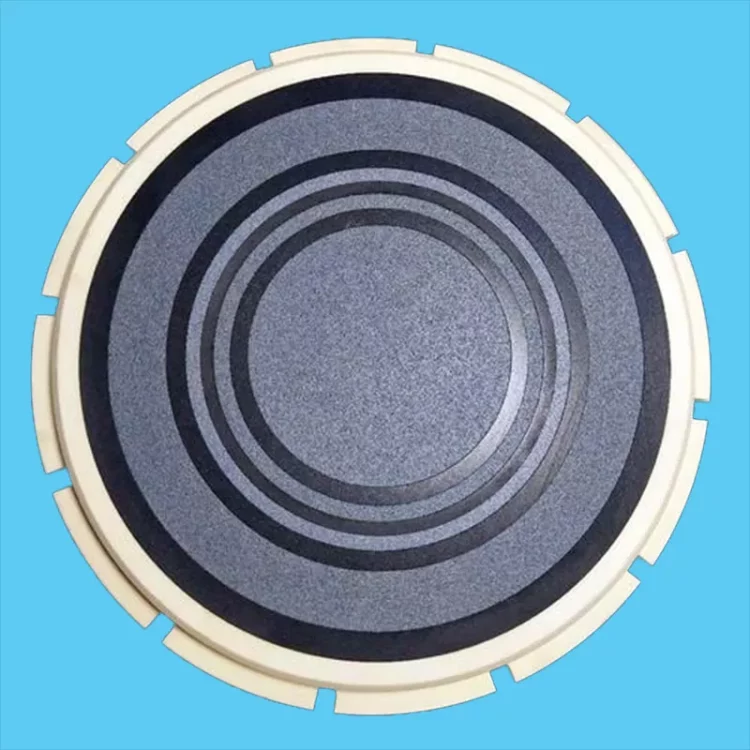

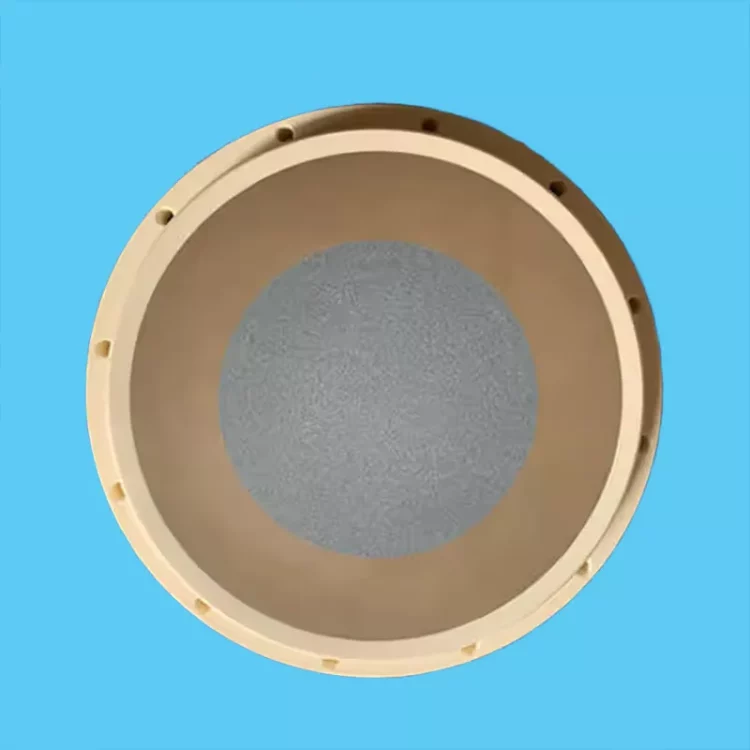

- Uniformly Distributed Aperture: Guarantees exceptional suction and holding force for even the thinnest films, keeping your workpieces stable and vibration-free throughout manipulation.

- Electronics and Semiconductor Industries: Tailor-made for these demanding sectors, our chucks seamlessly integrate into your existing production lines, becoming a trusted production partner.

- Customized Design: We understand your unique needs. GORGEOUS CERAMICS (GGS) offers customization options to suit your specific application, whether as a standalone workstation or seamlessly integrated into your existing setup.

- High-Precision Chuck: Our chucks boast superior parallelism, ranging from 1 micron on a 300 mm circle to less than or equal to 15 microns on a 500*500 mm size. This ensures your workpieces maintain exceptional precision during processing.

- Solution-Oriented Approach: While we specialize in Porous Vacuum Chucks, GORGEOUS goes the extra mile. We provide comprehensive solution suggestions and references, including optional pumps, to help you optimize your entire process. Save time, improve efficiency, and enjoy a worry-free experience.

Detailed Description

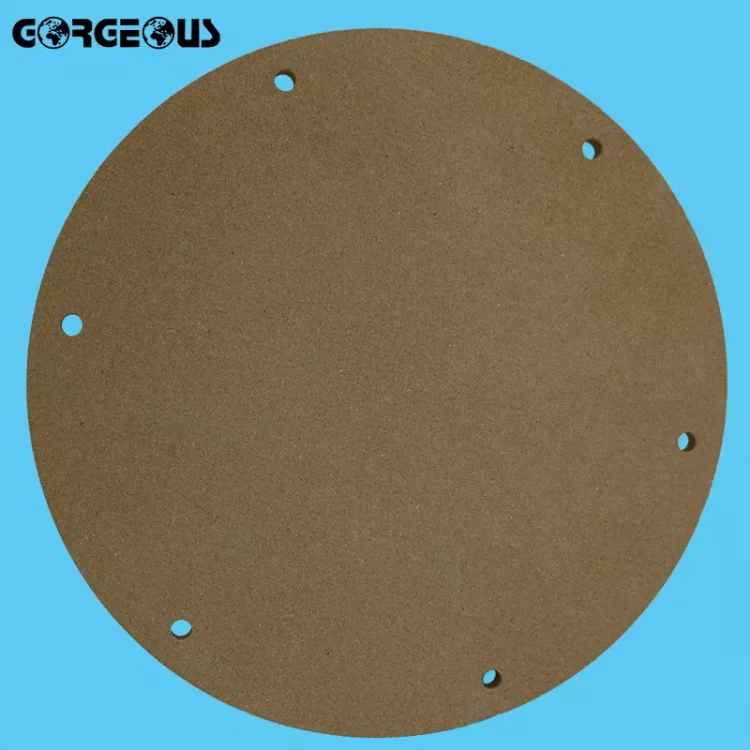

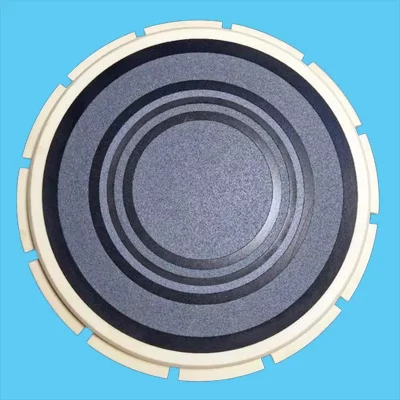

- Diverse Shapes and Sizes: We offer a wide selection of porous vacuum chucks in various shapes and sizes, including round, square, and rectangular. Choose from a range of standard sizes to perfectly match your workpiece processing needs, ensuring flexibility for diverse production scenarios.

- Quality Assurance: GORGEOUS prioritizes quality. Our chucks are crafted from high-grade ceramic materials, guaranteeing durability, stability, and the ability to withstand repeated use. This translates to a cost-effective, long-term investment.

- Competitive Pricing: We offer competitive prices, allowing you to acquire premium-quality products at an exceptional value. This translates to reduced production costs.

- Fast Delivery: Our efficient production processes ensure prompt delivery of your orders. Respond to market demands quickly and efficiently.

- Free Consultation and Design: GORGEOUS CERAMICS (GGS) welcomes your specific requirements. We provide complimentary consultation and design services to optimize your use of our products and help you troubleshoot production challenges with confidence.

Real-World Applications of Porous Vacuum Chucks:

- Electronics Industry: Porous vacuum suction cups are instrumental in the semiconductor chip production process. They enable the precise absorption and transport of ultra-thin wafers, ensuring they remain undamaged during handling while maintaining exceptionally high positioning accuracy.

- Solar Industry: These chucks are utilized for the adsorption and transportation of solar panels, preventing scratches or contamination. They guarantee that the panels remain stable throughout the process.

- Medical Industry: In the production and assembly of medical devices, porous vacuum chucks are employed to absorb and position delicate components such as precision sensors and catheter connectors. This ensures accurate alignment while preventing physical damage.

- Optical Laser Micromachining Industry: Our chucks are used to securely fix optical lenses during processing. This ensures the lenses remain absolutely still, guaranteeing processing accuracy and maintaining superior surface quality.

- MEMS Manufacturing: Porous vacuum chucks are perfectly suited for handling the tiny mechanical structural parts involved in MEMS manufacturing, meeting the industry.

Don’t Let the Processing of Thin Films and Flexible Workpieces Bother You Anymore!

Choose our Porous Vacuum Chuck product and let it become your most powerful assistant in this regard, making your production more efficient, convenient and safe. Please send your inquiry now!

Product Specifications

| Feature | Description |

|---|---|

| Material | High-quality ceramic |

| Shape | Round, square, rectangular |

| Size | Customizable |

| Pore Size | Uniformly distributed |

| Flatness | High precision (1 micron on a 300 mm circle to less than or equal to 15 microns on a 500*500 mm) |

| Application | Electronics, semiconductors, solar energy, medical, optical laser micromachining, MEMS |