Custom Ceramic Brazing to Stainless Steel: Achieve Superior Strength and Airtight Seals with GORGEOUS

Elevate Your Product Performance with Precision Ceramic Brazing

At GORGEOUS, we specialize in high-performance ceramic brazing solutions for stainless steel components. Our meticulous, multi-step process ensures exceptional strength, high-temperature resistance, and superior vacuum integrity for your assemblies.

Unparalleled Strength and Durability

Ceramic brazed joints exhibit remarkable tensile, shear, and fatigue strength, ensuring the longevity and reliability of your products. These joints can withstand extreme stresses and vibrations, making them ideal for demanding applications in:

- Aerospace and defense components

- Semiconductor and electronics equipment

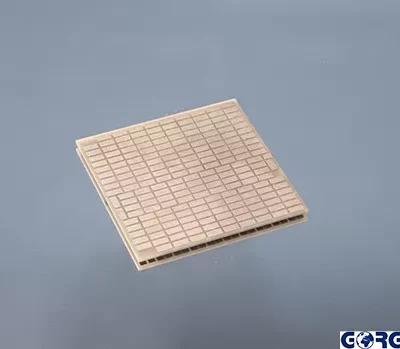

Semiconductor and electronics Aluminum Nitride Ceramic

- Medical devices and implants

- Fluid handling systems

- High-vacuum chambers

- Exhaust systems

Superior Airtight Seals

The brazing color is uniform, the welding texture is neat, and the appearance is perfect

The brazing process creates a hermetic seal, ideal for applications requiring exceptional vacuum integrity. Whether you’re dealing with sensitive electronics, medical devices, or high-vacuum chambers, our ceramic brazing ensures a leak-proof seal that maintains the integrity of your systems.

High-Temperature Performance

Ceramic brazed joints can withstand extreme temperatures, making them suitable for demanding environments. Our brazing materials are carefully selected to maintain their structural integrity and prevent degradation even in the most challenging thermal conditions.

Corrosion Resistance

The brazing material offers excellent corrosion resistance, protecting your joints from degradation and ensuring long-lasting performance. Whether you’re operating in harsh chemical environments or marine settings, our ceramic brazing safeguards your components from corrosion.

Design Flexibility

Our custom brazing process accommodates a wide range of stainless steel components and geometries. We can braze complex shapes, thin-walled parts, and even dissimilar materials, providing you with the flexibility to achieve your design goals.

GORGEOUS’s meticulous ceramic brazing process involves several key steps:

-

Pre-Cleaning: We meticulously prepare the ceramic and stainless steel components for brazing by first blowing away coarse particles with an air compressor. This is followed by ultrasonic cleaning to remove any remaining impurities and ensure a clean bonding surface. The components are then dried in a controlled environment for approximately 2 minutes.

-

Special Coating: A special coating is then applied evenly around the bonding surfaces using a dedicated coating gun. This coating enhances the brazing process by promoting strong adhesion between the ceramic and stainless steel.

-

Precise Docking and Drying: The gas-oxidized alumina ceramic parts and stainless steel parts are carefully docked together to ensure proper alignment. The docked components are then placed back in the oven for final drying to eliminate any moisture that could cause imperfections during brazing. We ensure a dryness level below 3% to prevent leakage and bubbles in the final joint.

-

Vacuum Brazing: The dried components are then placed in a vacuum furnace for brazing. The furnace maintains a precisely controlled temperature for a predetermined time (around 3 hours) to achieve optimal brazing results.

-

Quality Assurance: After brazing, the components are thoroughly inspected to ensure they meet our strict quality standards. As you can see, the finished product exhibits uniform welding, good fusion, and exceptional strength.

Why Choose GORGEOUS for Your Ceramic Brazing Needs?

- Extensive Experience: We possess a wealth of experience in ceramic brazing, ensuring we can deliver exceptional results for even the most complex applications.

- Advanced Techniques: We utilize state-of-the-art brazing equipment and techniques to guarantee consistent, high-quality joints.

- Stringent Quality Control: Our commitment to quality is unwavering. We adhere to rigorous quality control procedures throughout the entire brazing process.

- Exceptional Customer Service: We prioritize customer satisfaction and provide comprehensive support throughout every stage of the project, from initial consultation to final delivery.

Contact GORGEOUS Today to Discuss Your Custom Ceramic Brazing Requirements

If you’re seeking a reliable and high-performance solution for joining stainless steel components, look no further than GORGEOUS. Contact us today to discuss your custom ceramic brazing needs and discover how we can help you achieve superior results.

Enhance Your Product Performance with Custom Ceramic Brazing from GORGEOUS

Partner with GORGEOUS and experience the unparalleled strength, airtight seals, and high-temperature resistance of custom ceramic brazing. Our expertise and commitment to quality ensure that your stainless steel components meet the most demanding requirements.

The GORGEOUS Advantage: Precision Ceramic Brazing for Unmatched Performance

In addition to the exceptional benefits of ceramic brazing, choosing GORGEOUS provides several advantages:

- Advanced Brazing Techniques: We stay at the forefront of the industry, utilizing cutting-edge brazing technologies and materials to deliver optimal joint strength and integrity.

- Rigorous Quality Control: Our commitment to quality is evident in our stringent quality control procedures. Every step of the brazing process is meticulously monitored and inspected to ensure flawless results.

- Customizable Solutions: We understand that no two projects are exactly alike. We offer a high degree of customization to tailor our brazing solutions to your specific requirements, material combinations, and performance needs.

- Experienced Team: Our team of specialists possesses extensive experience in ceramic brazing and a deep understanding of its applications. We can provide expert advice, material selection guidance, and ensure your project runs smoothly.

Applications of GORGEOUS’s Custom Ceramic Brazing

Our custom ceramic brazing solutions are ideal for a wide range of applications across various industries. Here are a few examples:

- Aerospace and Defense: Heat shields, engine components, and high-performance equipment.

- Semiconductors and Electronics: Electronic packaging, heat sinks, and microfluidic devices.

- Medical Devices and Implants: Hip replacements, dental implants, and surgical instruments.

- Energy Technologies: Fuel cell components, heat exchangers, and thermal management systems.

- Chemical Processing Equipment: Reactors, vessels, and components for harsh chemical environments.

- Vacuum Systems: High-vacuum chambers, feedthroughs, and other critical components.

Ready to Experience the Power of Ceramic Brazing?

Contact GORGEOUS today to discuss your specific requirements and learn how our custom ceramic brazing solutions can elevate your product performance. Let our expertise and commitment to quality help you achieve superior results in your most demanding applications.