Inert alumina grinding balls

The main raw material of alumina grinding balls is alumina powder. After the ceramic is formed by rolling and isostatic pressing, it needs to be calcined at a high temperature above 1600°C. Alumina ceramics are divided into inert alumina balls and activated alumina balls. Inert balls are mainly used for grinding in industry. Its characteristics include good wear resistance, low wear, chemical inertness, and chemical corrosion resistance. Grind ceramic glazes, etc. in various ball mills and pulverizers.

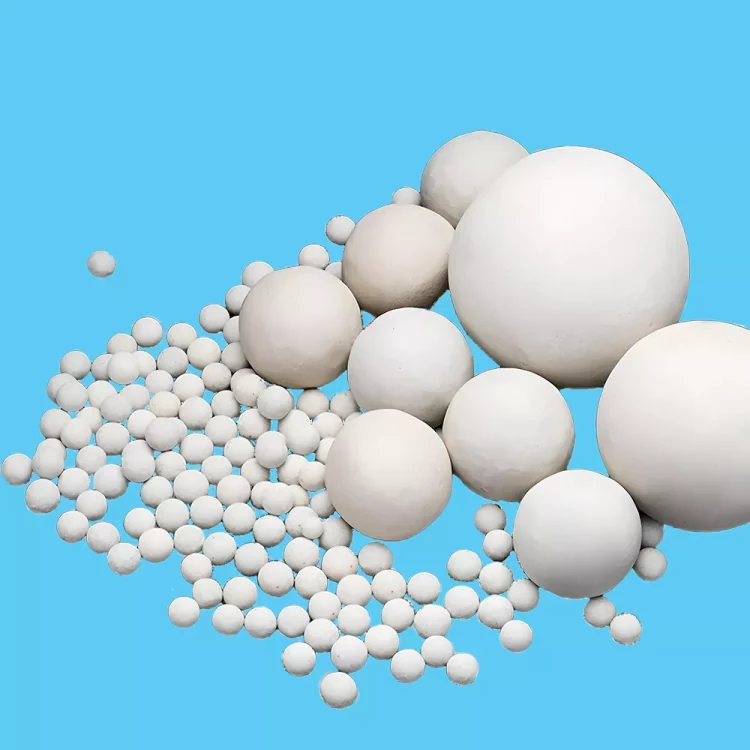

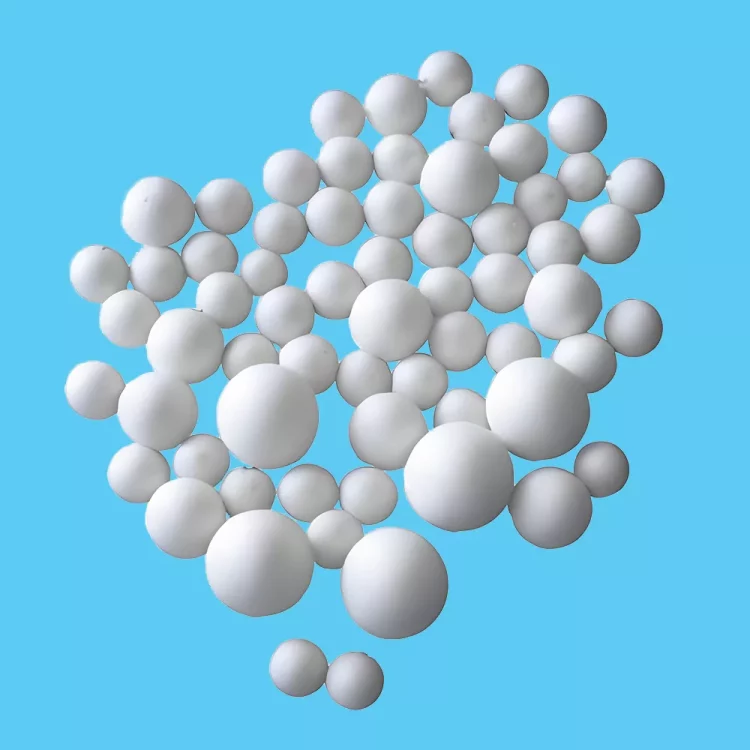

Our alumina wear-resistant balls mainly have two types of purity, 92% and 95%, and also have a variety of sizes for you to choose from: microbead sizes include 0.2-0.4mm, 0.5-1mm, 1.0-1.2mm, etc. Slightly larger grinding ball sizes are 1-90mm.

Inert alumina grinding ball parameters

|

Performance |

92 alumina grinding balls |

95 alumina grinding balls |

|

Aluminum oxide (%) |

92 |

95 |

|

iron oxide(%) |

≤0.02 |

≤0.02 |

|

Moh’s hardness |

9 |

9 |

|

Water absorption rate (%) |

≤0.01 |

≤0.01 |

|

Bulk density(g/cm3) |

≥3.65 |

≥3.70 |

|

Compressive strength |

≥2000 |

≥2250 |

|

Wear (%) |

≤0.10 |

≤0.08 |

* The above are the basic parameters of inert alumina grinding balls, which may vary under different customization conditions.

Inert alumina balls use

It is used as grinding media in fine grinding equipment such as ball mills, tank mills, and vibration mills. It can grind different types of ceramics, glass, etc., and further finely process thick and hard materials.

Why choose us?

We have a very professional team and a factory with more than 15 years of experience in producing high-grade ceramics;

We only produce high-quality aluminum ceramic balls, with inert balls and active balls for you to choose from. High-quality alumina is used as raw material, and advanced equipment is used to ensure the best wear resistance of the product;

We conduct strict product inspection. The key properties of alumina ceramics such as wear resistance and heat resistance will be fully tested before the product is shipped to ensure that the product delivered to you has optimal performance;

A group of R&D teams with professional knowledge are at your service at any time and can customize aluminum ball products for you according to the drawings you provide;

We enjoy a good reputation at home and abroad and are appreciated by many partners;

If you need a free sample of inert alumina ceramic balls, please contact us.

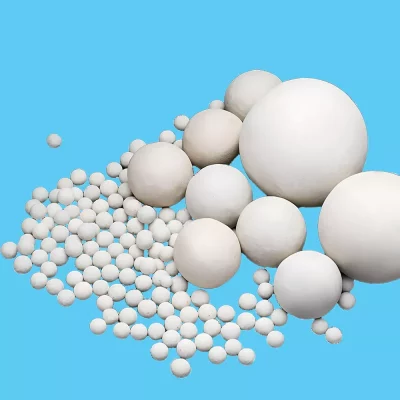

Package

We carefully package each product we send out to prevent the goods from being damaged during transportation. We ensure that the inert alumina balls delivered to you are of high quality and complete.