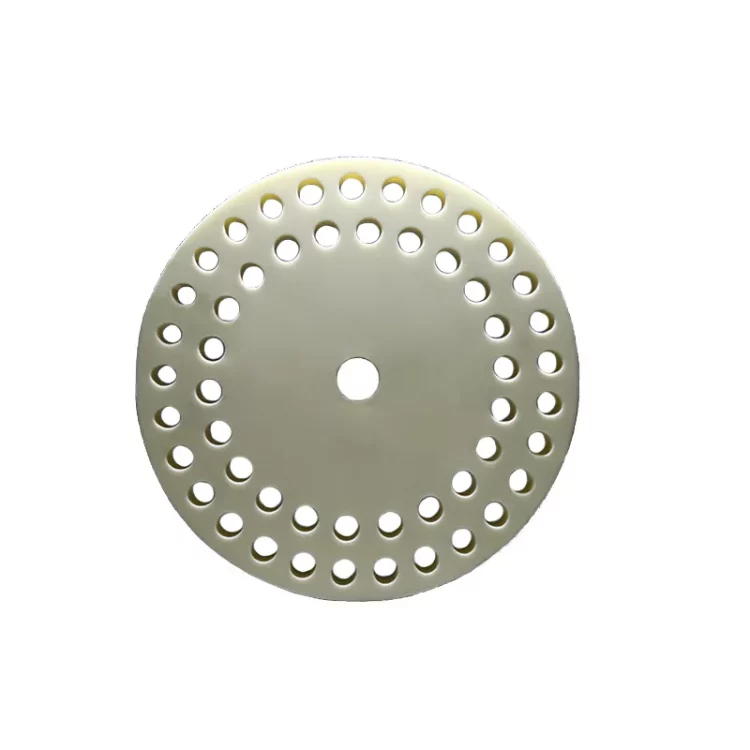

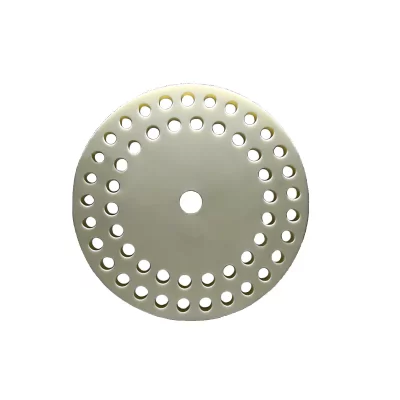

Alumina Disc,Aluminum Oxide Disc

Alumina is a high-quality material with high hardness, high temperature resistance, corrosion resistance, and strong insulation. These superior properties make alumina an indispensable material in industry.

Alumina discs are ceramics made of alumina and can be used in a variety of industries, such as circuit boards, wear-resistant discs, etc. We can customize exclusive high-performance alumina discs for you. If you need them, please contact us.

Alumina Disc Parameters

|

Characteristic |

Unit |

Value |

|

|

Purity |

– |

99 |

95 |

|

Density |

g/cm3 |

3.89 |

>3.6 |

|

Bending Strength |

Kpsi |

55 |

52 |

|

Compressive Strength |

Kpsi |

370 |

300 |

|

Operating Temperature |

℃ |

1600 |

1250 |

|

Hardness |

HV, GPa |

17.2 |

13.8 |

|

Dielectric Constant |

– |

9.7 |

9 |

|

Volume resistivity |

Ohm-cm |

>1014 |

>1014 |

*The above table shows typical parameters of common alumina materials under specific conditions. Custom alumina ceramic properties will vary depending on the purity and process chosen. We can provide custom alumina pan service according to your drawings.

Alumina Disc Uses

Substrates and circuit boards;

Electrical insulation;

Wear-resistant discs;

Mechanical seals;

Furnace bottom plates and heating element brackets;

Why Choose Us?

GORGEOUS has 15 years of experience in producing advanced ceramics, and can help you solve various common problems. You can ask us any questions you encounter, and our experts will solve them for you!

We only produce high-quality ceramics, using the best raw materials and equipment to bring you the most superior performance ceramics.

A group of R&D teams with rich professional knowledge are at your service at any time. If you need customized advanced ceramics, please choose us!

Packaging

We carefully package each product to prevent your Al2O3 ceramic products from being damaged during transportation. We ensure that the Alumina Disc products delivered to you are of high quality and complete.