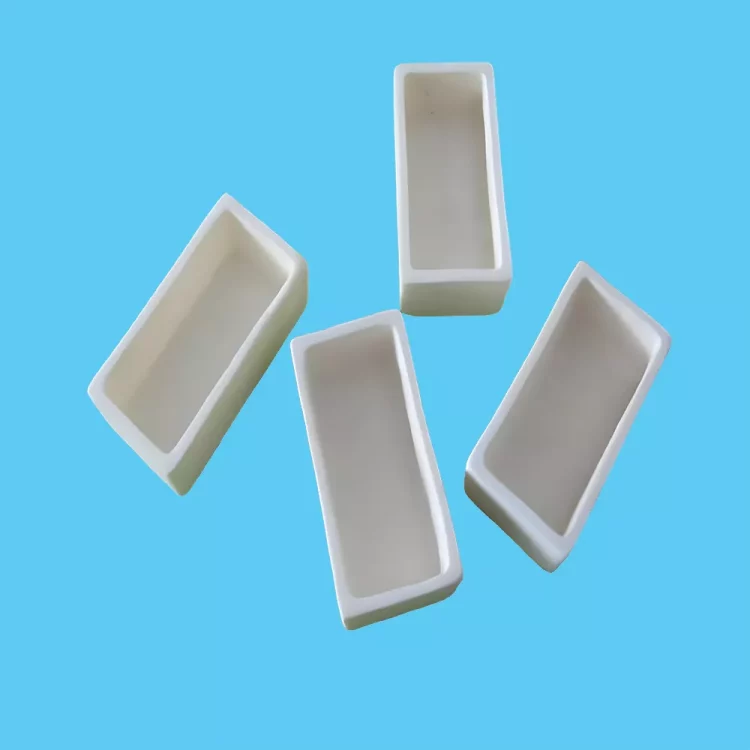

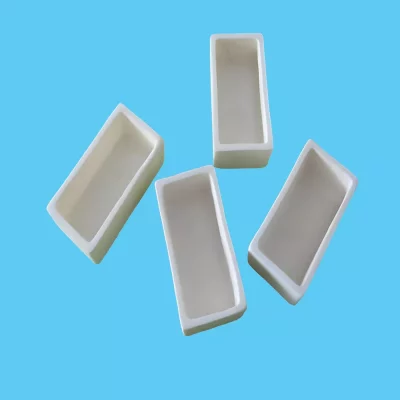

Alumina Boat,Al2O3

Alumina boats are made of high-quality alumina through multiple fine processing techniques. Its high temperature resistance makes it a commonly used instrument in laboratories and industries. Alumina ceramic trays and alumina ceramic boats can withstand high temperatures of 1600°C, or even higher in some special atmospheres. Ceramic trays and ceramic boats are used for sintering and heat treatment of ceramics, metals and other materials. Their high temperature stability makes them less likely to react with samples.

We have a variety of purities for you to choose from. Alumina boats of different purities have slightly different properties. The higher the purity, the stronger its heat and high temperature resistance. For example, 99 alumina ceramics can withstand higher temperatures than 95 alumina ceramics, and all kinds of properties are more superior.

If you have demand for high-quality alumina ceramic trays、rectangle alumina ceramic boat crucible,please contact us. Our professional team can provide you with customized ceramic boat crucible of different purity and specifications.

Aluminum oxide properties

|

project |

condition |

Performance parameters |

unit |

|

|

95 |

99 |

|||

|

Bulk density |

– |

≥3.65 |

≥3.85 |

g/cm3 |

|

Air tightness |

– |

qualified |

qualified |

|

|

Flexural strength |

– |

≥280 |

≥300 |

KPa |

|

Average linear expansion coefficient |

25℃~500℃ |

7~7.5×10-6 |

7~7.5×10-6 |

1/K |

|

25℃~800℃ |

7~7.5×10-6 |

7~7.5×10-6 |

1/K |

|

|

Dielectric constant |

1MHz |

9~10 |

9~10.5 |

– |

|

(10±0.5)GHz |

||||

|

Dielectric loss tangent |

1MHz |

≤3×10-4 |

≤4×10-4 |

– |

|

(10±0.5)GHz |

≤6×10-4 |

≤6×10-4 |

– |

|

|

Volume resistivity |

25℃ |

≥1×10-14 |

≥1×10-14 |

Ω.cm |

|

300℃ |

≥1×10-11 |

≥1×10-11 |

||

|

Breakdown strength |

D.C |

≥20 |

≥30 |

KV/mm |

|

Average grain size |

– |

10~20 |

8~16 |

μm |

*The table above only shows typical properties of common alumina materials. The characteristics of custom alumina ceramic boats will vary depending on the purity and process chosen.

Alumina boat uses

- High temperature sintering and heat treatment of materials:Other materials can be placed to help with high-temperature sintering and heat treatment, such as annealing, quenching, tempering, etc.

- chemical reactor:Its resistance to chemical corrosion allows it to store chemicals and serve as a reactor for some reactions.

- Powder drying and baking: used to place chemical powder to help dry and bake it.

- Elemental analysis: Alumina boats can place samples and heat them in a high-temperature furnace for elemental analysis.

Why choose us?

GORGEOUS has obtained ISO 9001:2015 quality management certification and IATF 16949:2016 automotive industry quality management system certification. This means we can provide you with higher quality products and services!

Our Goal!

✅ Finished product qualification rate ≥ 95%

✅ On-time delivery rate ≥ 90%

✅ Customer satisfaction ≥ 90%

We can provide you with

Multiple purity options: 95% and 99% alumina boats.

Customized service: Products of various specifications and sizes can be customized according to your drawings and requirements.

Free samples: Free sample testing is provided.

Package

Gorgeously and carefully package each of your products to prevent the goods from being damaged during transportation. We ensure that the aluminum oxide pallets delivered to you are of high quality and complete.

Contact us now!

If you need high-quality alumina ceramic boats, ceramic trays, please contact us now. We will serve you wholeheartedly!