Alumina Lining Brick , Alumina Lining , Al2O3

Alumina is a highly wear-resistant ceramic material. GORGEOUS CERAMICS (GGS) is a professional advanced ceramic manufacturer that can customize exclusive ceramic products for you!

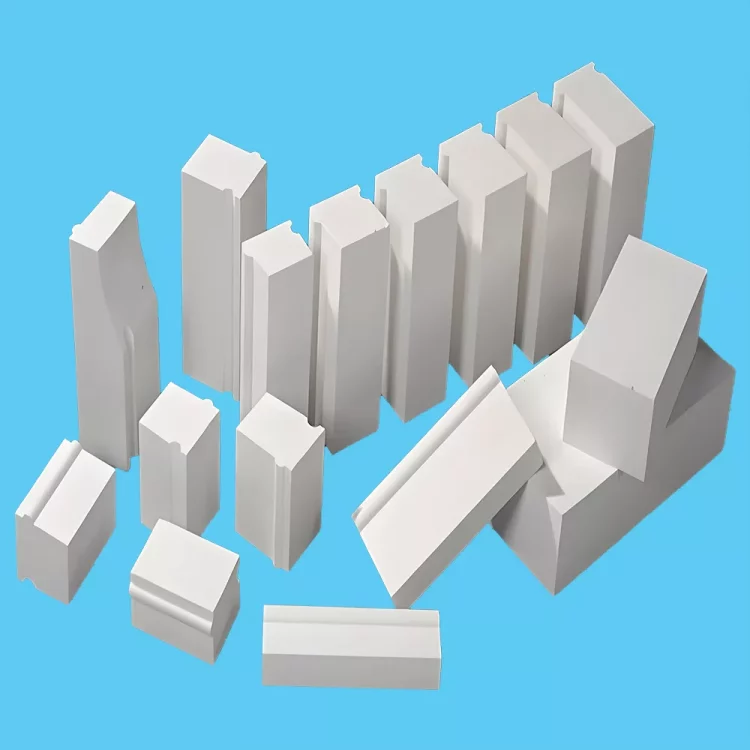

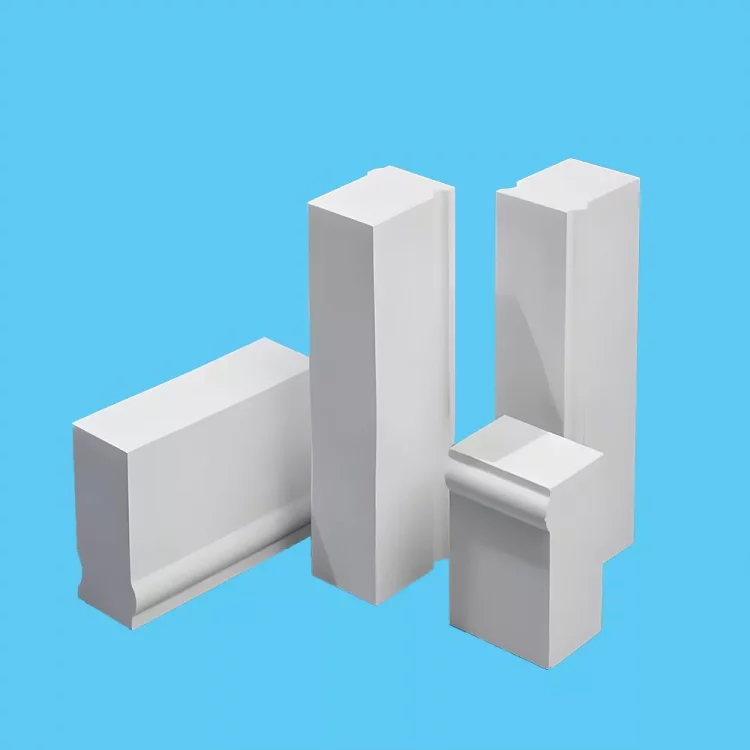

Alumina lining bricks come in various shapes. You only need to provide us with drawings and we can customize advanced ceramics of various shapes for you.

We have a variety of alumina ceramics with different purities for you to choose from. In addition, we can recommend the most suitable materials for you according to your application.

Alumina lining bricks are used in various industrial scenarios such as steel and cement. For those occasions where the environment is harsh and extreme wear resistance is required, it is very suitable to use alumina ceramic lining bricks. Ceramic lining bricks have better wear resistance than steel lining (266 times that of manganese steel), and even high-intensity operations rarely crack.

|

performance |

unit |

value |

|

Purity |

% |

92 |

|

Bulk density |

g/cm3 |

>3.6 |

|

Moh’s hardness |

– |

9 |

|

Wear Loss |

% |

<0.01 |

Disclaimer: The above parameters are summarized based on production experience. Data are measured under certain conditions. Different conditions may be slightly different and are for purchase reference only.

Application of Alumina Lining Brick

Cement industry: In cement production equipment, it can prevent equipment from being worn by cement particles.

Mining and metallurgical industry: Used for lining of various grinding equipment, such as ball mills, vibration mills, etc., which can effectively reduce equipment wear and extend equipment service life.

Steel industry: Used for lining of high-temperature smelting equipment to provide high temperature and wear protection.

Why Choose Us

GORGEOUS CERAMICS (GGS) is a company with more than 15 years of professional production of advanced ceramics. Our ceramics are produced in a million-level seamless workshop, using the highest quality raw materials and equipment to ensure that your ceramics are at their best performance.

Package

We carefully pack your ceramics to ensure that they are intact when delivered to you. You don’t have to worry about the goods being damaged during transportation, as we will compensate you.