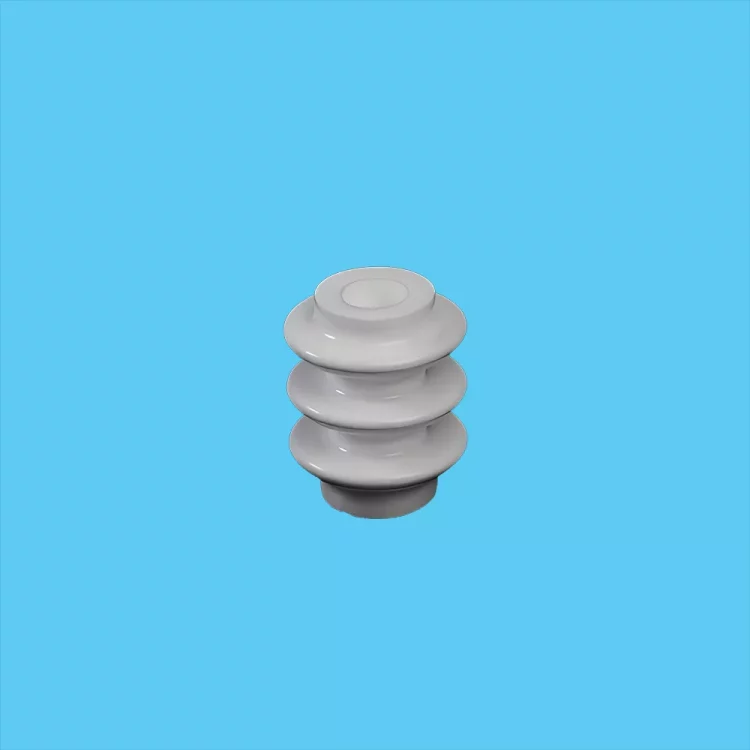

Alumina Insulator , Alumina Ceramic Insulator , Al2O3

Alumina insulators are commonly used electrical component insulators that can meet your various high-intensity applications in the electrical industry!

GORGEOUS CERAMICS (GGS) can provide you with customized high-quality, cost-effective alumina insulators (dielectric loss ≤ 0.0001 (1MHz)). It has very superior wear resistance and corrosion resistance, can work stably at high temperatures, and can adapt to various harsh environments!

If you need customized alumina insulators, please contact our professionals immediately. Multiple materials and purities are available for you to choose from!

Performance Parameters of Alumina

|

|

performance |

99 Alumina Ceramic |

95 Alumina Ceramic |

|

|

purity |

Al2O3≥99% |

Al2O3≥99% |

|

Physical properties |

density |

3.85 |

3.6 |

|

water absorption(%) |

0 |

0 |

|

|

Sintering temperature(℃) |

1690 |

1600 |

|

|

Material properties |

Hardness(HV) |

1700 |

1600 |

|

Flexural strength 4pt |

>3500 |

>2900 |

|

|

Compressive strength kgf/cm2 |

30000 |

25000 |

|

|

Thermal properties |

Operating temperature℃ |

1500 |

1400 |

|

Thermal expansion coefficient |

8 |

7.8 |

|

|

10-6/℃ |

|||

|

0-1000℃ |

|||

|

Thermal shock resistance T (℃) |

200 |

220 |

|

|

Thermal conductivity (W/m.k) |

31 |

22 |

|

|

Electrical characteristics |

Volume resistivityΩ.cm |

>1012 |

>1012 |

|

Insulation destruction force (KT/m) |

18 |

16 |

|

|

Dielectric constant 1MH9Z (E) |

9.2-10.5 |

9.0-10 |

Disclaimer: The above data are performance parameters tested based on our production experience. The performance of the product will be slightly different under different conditions and is for purchase reference only.

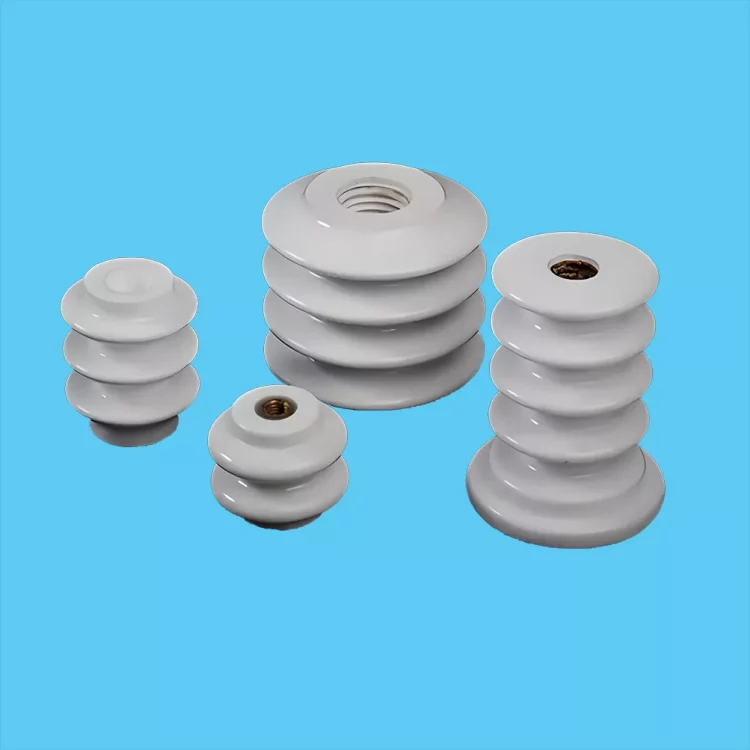

Alumina Insulator Uses

Insulators are widely used in various industries, especially in the electrical industry. Because of its superior insulation performance, alumina is a very superior insulating material! Alumina insulators are used in high-voltage transmission lines, substation equipment, cable joints and other applications!

Power industry: Many insulating parts of transformers, switchgear, circuit breakers and other equipment are made of alumina! Its powerful performance makes it more durable than other materials!

Electronic industry: Alumina insulators are very good protectors. Some precision semiconductors, electronic tube devices, integrated circuit substrates, etc. cannot do without its protection. Its superior insulation and high temperature resistance make alumina a very stable protective and heat dissipating material.

In addition, alumina insulators are also widely used in other industries, such as high-temperature components and insulating materials in the aviation industry, and insulating materials in microwave communication equipment. Alumina ceramic insulators can provide stable electrical performance and extremely low loss.

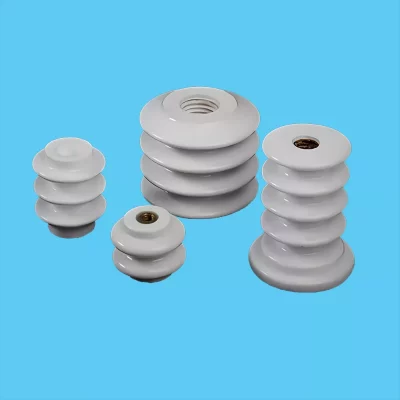

Strong Strength

We have more than 15 years of experience in the production of advanced ceramics, and we select the best quality alumina as raw materials, which can provide you with better customized services.

We are determined to do our best in product quality control. A group of R&D teams with rich professional knowledge are at your service at any time. If you need customized alumina ceramics, please contact us immediately!

pack

We carefully package each product to prevent damage during transportation. We ensure that the aluminum oxide insulators delivered to you are of high quality and complete.