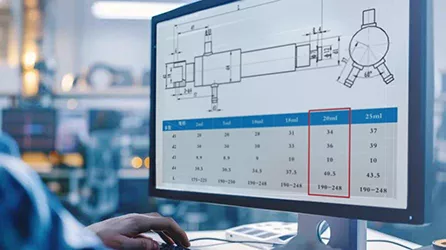

Wir bieten umfassende kundenspezifische Fertigungsdienstleistungen zur Herstellung hochpräziser, komplexer Teile an.

Erfahrung im Entwurf und der Entwicklung kundenspezifischer fortschrittlicher Keramiklösungen für verschiedene Anwendungen.

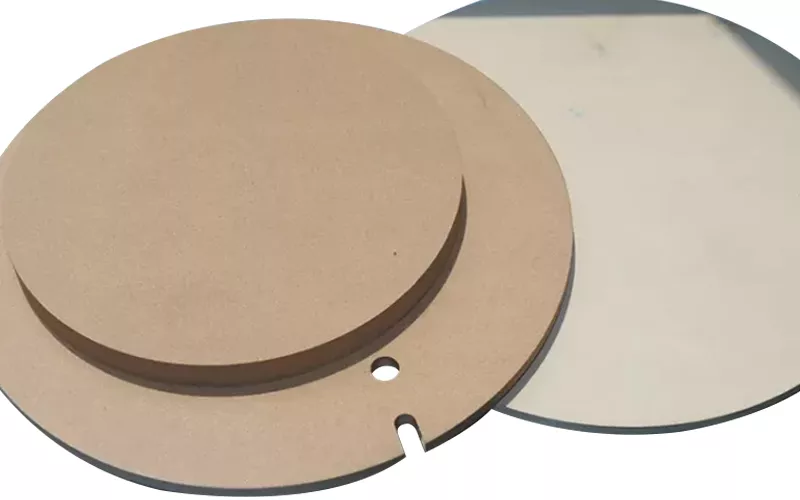

Wir verfügen über umfangreiche Erfahrung im Fräsen, Schleifen und Polieren von hochpräzisen technischen Keramiken.

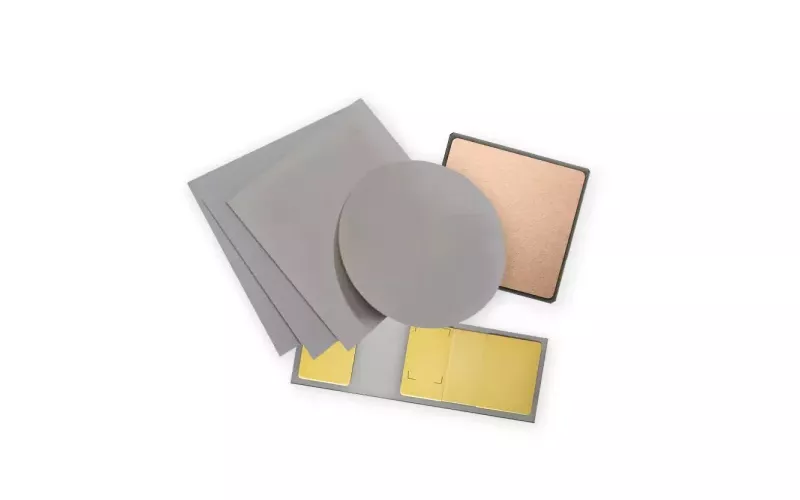

Anpassbare Keramikmaterialien

Wir bieten eine breite Auswahl an Hochleistungskeramikwerkstoffen, darunter Aluminiumoxid, Zirkoniumdioxid, Aluminiumnitrid, Siliziumnitrid, Bornitrid, Siliziumkarbid, Borkarbid und Berylliumoxid. GORGEOUS CERAMICS (GGS) unterstützt Sie bei der Auswahl der optimalen Materiallösung für Ihre Anwendungsanforderungen und erzielt so das beste Verhältnis von Leistung und Kosten.

GORGEOUS Bestseller-Produkte!

Wir decken den Bedarf verschiedenster Branchen an Hochleistungskeramik. Ob Sie standardmäßige, hochtemperaturbeständige und korrosionsbeständige Keramikkomponenten, hochpräzise Keramikteile für die Halbleiterindustrie oder Keramikheizungen mit schneller Reaktionszeit und hoher Energieeffizienz benötigen – wir bieten Ihnen bewährte, leistungsstarke und kundenspezifische Lösungen für einen reibungslosen Übergang von der Entwicklung zur Serienproduktion.

Below are some of GORGEOUS CERAMICS (GGS) best-selling products!

Keramikheizung

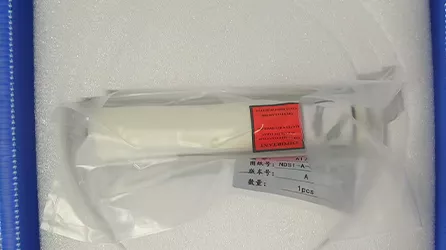

Keramikzünder

Keramiksubstrat

Halbleiterkeramik

Mikroporöse Keramik

Durchführung

GORGEOUS CERAMICS (GGS)

– Ihr vertrauenswürdiger Partner

Produkte werden weltweit verkauft

GORGEOUS CERAMICS (GGS) mit Hauptsitz in China exportiert seine hochentwickelten Keramikprodukte weltweit und hat sich zum Ziel gesetzt, seinen Kunden schnelle, qualitativ hochwertige und bedarfsgerechte Fertigungslösungen anzubieten.

Als führender Anbieter von Hochleistungskeramik in China unterstützen wir den weltweiten Versand und liefern in nur 3–10 Tagen in wichtige Regionen Nordamerikas und Europas.

Unsere Projektingenieure beherrschen die englische Sprache fließend. An Werktagen reagieren wir schnell, gehen nahtlos auf die Bedürfnisse unserer Kunden über verschiedene Zeitzonen hinweg ein und gewährleisten einen reibungslosen Projektablauf von der Prototypenentwicklung bis zur Auslieferung.

30,000㎡ 20,000+ 120+

Factory floor area Global customers The country of service

Von der Produktentwicklung bis zu Lösungen

GORGEOUS CERAMICS (GGS) offers more than just manufacturing services. We provide full-cycle product development solutions, from design and prototyping to production and packaging.

Maßgeschneiderte Hochleistungskeramik für verschiedene Branchen

Unsere Keramikprodukte finden in einer Vielzahl von Branchen Anwendung, darunter Luft- und Raumfahrt, Automobilindustrie, Halbleiterelektronik, Maschinenbau, Chemie und Medizin.

Luft- und Raumfahrt

Automobilindustrie

Elektronik

Maschinenbau

Medizinisch

Chemisch

Unsere Anwendungen zur Keramikherstellung

GORGEOUS CERAMICS (GGS) bietet kundenspezifische Keramikfertigung zur Herstellung von Strukturen, Maschinen und Teilen an, darunter:

Was unsere Kunden sagen

GORGEOUS hat sehr gut mit uns kommuniziert, unsere Bedürfnisse immer genau verstanden und zeitnah geantwortet.

Karl

Ihre Produktionsgeschwindigkeit ist erstaunlich, unsere Bestellungen werden immer pünktlich geliefert, die Qualität ist ausgezeichnet und die Zusammenarbeit mit ihnen macht Spaß.

SIE ZAN

Wir sind mit dem Service sehr zufrieden! Sie lösen alle Probleme sofort und arbeiten professionell und effizient. Vielen Dank an GGS!

Hans

Verwandte Ressourcen

Applications of Silicon Carbide Bearings and Shafts in High-Speed and Wear-Intensive Industries

Standard material-made bearings often fail in harsh chemical, advanced engineering, and fast-moving industries. Rather, silicon carbide bearings perform exceptionally well in these fields.Let’s explor…

Silicon Carbide vs Steel FGD Nozzles: Which Reduces Downtime?

Steel desulfurization nozzles fail in 6-12 months due to wear and clogging. Silicon carbide nozzles last 3-5 years with excellent corrosion resistance. This guide covers performance comparison, total …

Silicon Carbide Bulletproof Plate: Lightweight, Reliable & Safe

Your silicon carbide bulletproof plate offers exceptional hardness, low density, and great shock resistance. In your defense equipment manufacturing, SiC translates to superior, lightweight bulletproo…

Senden Sie ein schnelles Angebot

Warum GORGEOUS das Vertrauen genießt von 1000+ Kunden?

Unsere industrielle Keramikfertigung bietet vielfältige Vorteile für verschiedene Branchen, Unternehmen und Projekte. Hier sind die Vorteile unserer Dienstleistungen.

Kostengünstige und schnelle Produktion

GORGEOUS kann schnell verschiedene Keramikprototypen und Endprodukte herstellen. GORGEOUS bietet schnelle Produktion bei gleichzeitig hoher Präzision. Unsere Großserienproduktion ermöglicht uns zudem die kostengünstige Keramikfertigung.

Hervorragendes Verhältnis von Festigkeit zu Gewicht

Dank unserer fortschrittlichen Fertigungstechnologie können wir hochwertige und zugleich langlebige Keramikteile herstellen. Wir garantieren hohe Festigkeit, Kratzfestigkeit und Korrosionsbeständigkeit für alle hergestellten Keramikprodukte.

Große Auswahl an verwendeten Materialien und Techniken

Wir sind Experten in verschiedenen Fertigungstechniken für keramische Materialien, die es uns ermöglichen, komplexe Teile mit zusätzlichen komplizierten Merkmalen wie Kerben, Schlitzen, Löchern usw. herzustellen. Unsere große Auswahl an keramischen Materialien ist zudem hitzebeständig, korrosionsbeständig und mehr.