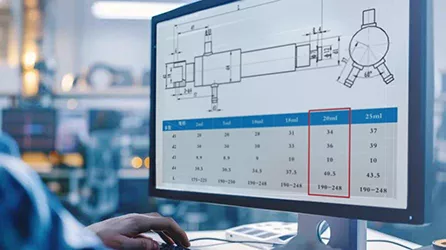

Proporcionamos servicios integrales de fabricación personalizados, utilizando diversos materiales de proceso para producir piezas complejas y de alta precisión.

Experiencia en el diseño y desarrollo de soluciones cerámicas avanzadas personalizadas para diversas aplicaciones.

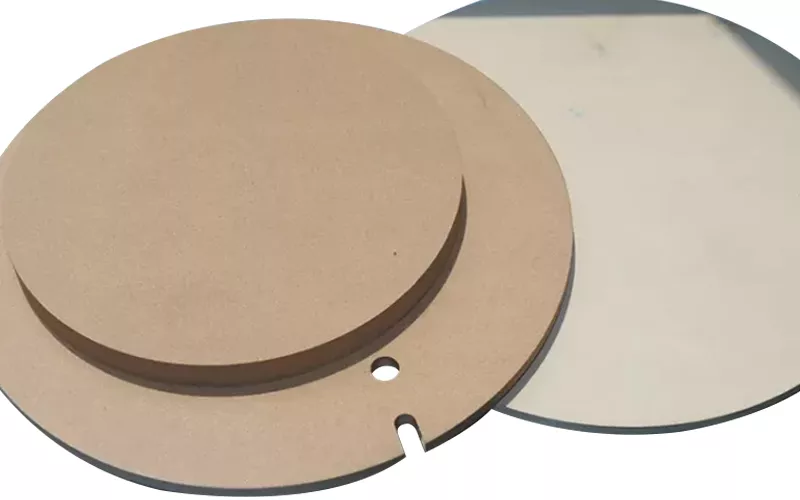

Disponemos de una amplia experiencia en el fresado, rectificado y pulido de cerámica técnica de alta precisión.

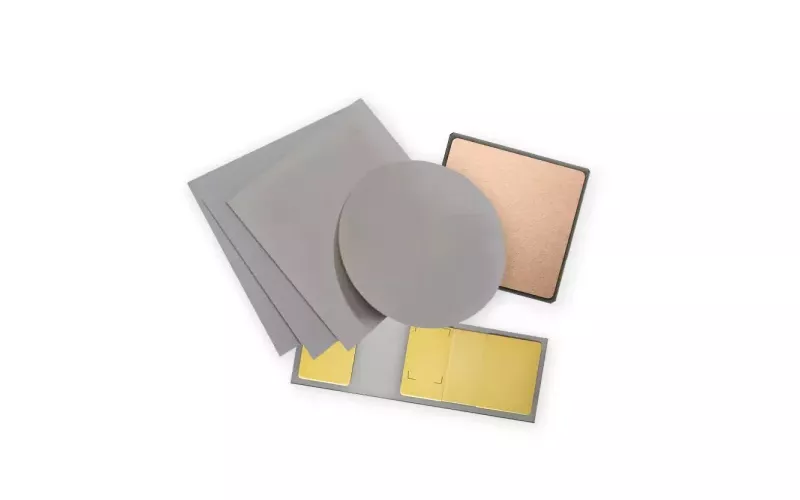

Materiales Cerámicos Personalizables

Ofrecemos una amplia selección de materiales cerámicos de alto rendimiento, que incluyen alúmina, óxido de circonio, nitruro de aluminio, nitruro de silicio, nitruro de boro, carburo de silicio, carburo de boro y óxido de berilio. GORGEOUS CERAMICS (GGS) le ayudará a seleccionar la solución de material más adecuada según sus requisitos de aplicación, logrando el equilibrio óptimo entre rendimiento y coste.

GORGEOUS CERAMICS (GGS) ¡Los Productos Más Vendidos!

Atendemos las necesidades cerámicas avanzadas de diversas industrias. Ya sea que sus requisitos incluyan componentes cerámicos estándar resistentes a altas temperaturas y a la corrosión, piezas cerámicas de alta precisión para la industria de semiconductores o calentadores cerámicos de respuesta rápida y alta eficiencia energética, podemos ofrecerle soluciones personalizadas de alto rendimiento y eficacia comprobada, logrando una transición fluida del diseño a la producción en masa.

A continuación se muestran algunos de los productos más vendidos de GORGEOUS CERAMICS (GGS).

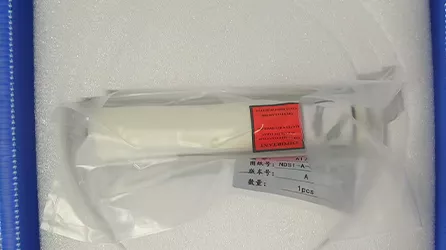

Calentador de cerámica

Encendedor de cerámica

Sustrato cerámico

Cerámica semiconductora

Cerámica microporosa

Alimentación continua

GORGEOUS CERAMICS (GGS)

– Su Socio De Confianza

Productos vendidos en todo el mundo

Con sede en China, GORGEOUS CERAMICS (GGS) exporta sus productos cerámicos avanzados a todo el mundo, con el objetivo de proporcionar a sus clientes soluciones de fabricación rápidas, de alta calidad y bajo demanda.

As a leading advanced ceramic supplier in China, we support global shipping, delivering to major regions in North America and Europe in as little as 3–10 days.

Nuestros ingenieros de proyecto dominan el inglés a la perfección. De lunes a viernes, respondemos con rapidez, conectándonos sin problemas con las necesidades de los clientes en diferentes zonas horarias y garantizando un desarrollo fluido del proyecto, desde el prototipado hasta la entrega final.

30,000㎡ 20,000+ 120+

Factory floor area Global customers The country of service

Desde el desarrollo de nuevos productos hasta las soluciones.

GORGEOUS CERAMICS (GGS) ofrece mucho más que simples servicios de fabricación. Proporcionamos soluciones integrales para el desarrollo de productos, desde el diseño y la creación de prototipos hasta la producción y el embalaje.

Cerámica avanzada personalizada para diferentes industrias

Nuestros productos cerámicos tienen una amplia gama de aplicaciones, que incluyen los sectores aeroespacial, automotriz, de electrónica de semiconductores, maquinaria, química y médico.

Aeroespacial

Automotor

Electrónica

Ingeniería Mecánica

Médico

Químico

Nuestras aplicaciones de fabricación de cerámica

GORGEOUS CERAMICS (GGS) ofrece fabricación de cerámica a medida para crear estructuras, máquinas y piezas, incluyendo:

Lo que dicen nuestros clientes

GORGEOUS se comunicó muy bien con nosotros, siempre entendió nuestras necesidades con precisión y respondió de manera oportuna.

Carlos

Su velocidad de producción es asombrosa, nuestros pedidos siempre se entregan a tiempo, la calidad es excelente y es un placer trabajar con ellos.

ELLA ZAN

¡Estamos muy contentos con su servicio! Solucionan cualquier problema de inmediato, demostrando profesionalismo y eficiencia. ¡Muchísimas gracias a GGS!

Hans

Recursos relacionados

Applications of Silicon Carbide Bearings and Shafts in High-Speed and Wear-Intensive Industries

Standard material-made bearings often fail in harsh chemical, advanced engineering, and fast-moving industries. Rather, silicon carbide bearings perform exceptionally well in these fields.Let’s explor…

Silicon Carbide vs Steel FGD Nozzles: Which Reduces Downtime?

Steel desulfurization nozzles fail in 6-12 months due to wear and clogging. Silicon carbide nozzles last 3-5 years with excellent corrosion resistance. This guide covers performance comparison, total …

Silicon Carbide Bulletproof Plate: Lightweight, Reliable & Safe

Your silicon carbide bulletproof plate offers exceptional hardness, low density, and great shock resistance. In your defense equipment manufacturing, SiC translates to superior, lightweight bulletproo…

Envíe una cotización rápida

Por qué GORGEOUS tiene la confianza de 1000+ ¿clientes?

Nuestra fabricación industrial de cerámica aporta numerosos beneficios a diversas industrias, negocios o proyectos. Estas son las ventajas de nuestros servicios.

Producción asequible y rápida

GORGEOUS puede producir rápidamente diversos prototipos y productos finales de cerámica. GORGEOUS ofrece una producción rápida con alta precisión. Nuestra producción a gran escala también nos permite ofrecer servicios de fabricación de cerámica rentables.

Excelente relación resistencia-peso

Gracias a nuestra avanzada tecnología de fabricación, podemos producir piezas cerámicas de alta calidad y durabilidad. Garantizamos alta resistencia, resistencia al rayado y a la corrosión en todos nuestros productos cerámicos.

Amplia gama de materiales y técnicas utilizadas

Somos expertos en diferentes técnicas de fabricación de materiales cerámicos que nos permiten producir piezas complejas con características adicionales como muescas, ranuras, agujeros, etc. Nuestra amplia gama de materiales cerámicos también puede soportar resistencia térmica, resistencia a la corrosión y más.