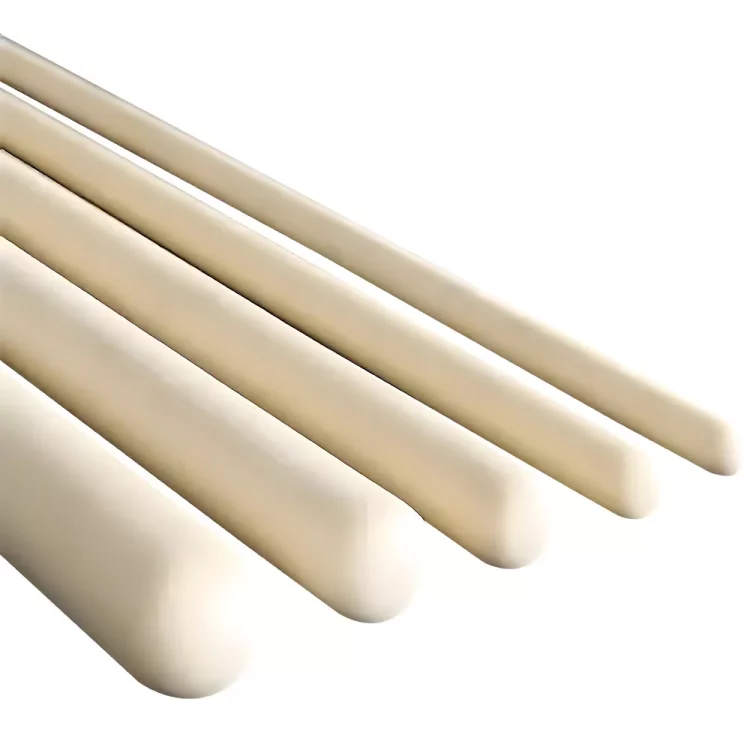

Thermocouple Protection Tube/Ceramic Thermocouple Protection Tubes

Thermocouple protection tubes are generally ceramic tubes with one end closed. They are ceramic tubes designed specifically for protecting thermocouples. GORGEOUS CERAMICS (GGS) is a professional supplier of advanced ceramics and can provide customers with high-quality ceramic protection tubes.

GORGEOUS CERAMICS (GGS) produces thermocouple protection tubes for customers with excellent performance. Thick wall tube (HWT) adopts thicker wall design to provide higher mechanical strength and durability. As the external protection of thermocouples, it can significantly increase the service life of the product. Customized ceramic tubes have a variety of materials to choose from, such as alumina, mullite, silicon carbide, etc., and customized sizes can be selected from 1 mm to 100 mm. You can provide us with drawings and we will give you the best customized solution.

Thermocouple Protection Tube Description

Ceramic protection tubes can protect platinum thermocouple elements or other precious metal thermocouples working at high temperatures of 1200°C, ensuring that the thermocouples measure temperature accurately and extend their service life.

When the general protection tube (such as mullite protection tube) is used at a temperature exceeding 2200°F (1200°C), the silica contained in the protection tube will contaminate the platinum. The protection tubes we produce are usually 99.8% pure and contain only a very small amount of flux (silicon dioxide concentration is very low, less than 100 ppm). While protecting the platinum from being contaminated by silica, the superior thermal conductivity of alumina can also ensure accurate temperature measurement.

If you want to better protect the Bo thermocouple or other precious metal thermocouples, we recommend you use our alumina protection tube!

Key Performance of Ceramic Thermocouple Protection Tubes

|

Parameter |

Specification Range |

|

Outer Diameter (OD) |

1mm - 100mm |

|

Inner Diameter (ID) |

0.5mm - 90mm |

|

Length |

50mm - 2000mm |

|

Wall Thickness |

0.5mm - 10mm |

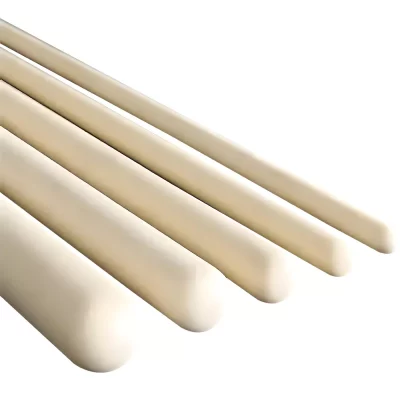

High temperature resistance: As a protective tube, it needs excellent high temperature performance. Alumina thermocouple protection tubes can withstand high temperatures of 1600°C under normal conditions and can withstand extremely high temperatures of 1750°C for a short time under special atmospheres (such as redox atmospheres).

Thermal shock resistance: The thermal shock resistance of ceramic thermocouple protection tubes is the key. The excellent thermal shock resistance allows the protection tube to perform stably at high temperatures and is not easy to crack or oxidize. (Please note that the maximum temperature change rate of the protection tube during use shall not exceed 150°C/Hr).

Corrosion resistance: Alumina has good chemical inertness, which enables ceramic protection tubes to resist corrosion from most chemicals (such as acids, alkalis, and salts), thereby providing additional protection for thermocouples.

Application Areas of Alumina Thermocouple Protection Tubes

Thermocouples are needed in various high-temperature industries, chemical industries, power industries, etc., but some industries are often in harsh environments, and alumina thermocouple protection tubes can play a good protective role.

High-temperature industries are often in high-temperature environments. Alumina thermocouple protection tubes can effectively protect thermocouples, allowing them to accurately measure the temperature of furnace equipment.

In the chemical industry, thermocouples need to come into contact with various corrosive chemicals. Alumina ceramic tubes are corrosion-resistant and can effectively protect thermocouples from corrosion by various chemicals, extend the service life of thermocouples, and make the production process safer and more efficient.

In the power industry, thermocouples work in thermal power plants and nuclear power plants. In these environments, high temperature and high pressure are usually present. Alumina tubes have good heat resistance and electrical insulation, which can protect thermocouples from environmental influences to a large extent.

Alumina thermocouple protection tube has many superior properties such as high temperature resistance, corrosion resistance, high hardness, high wear resistance, insulation resistance, etc., making it an excellent material for protecting thermocouples.

Packaging

We carefully package each product to prevent damage during transportation. We ensure that the alumina thermocouple protection tubes delivered to you are of high quality and complete specifications.

Contact Us Now!

If you need high-quality alumina thermocouple protection tubes, please contact us immediately. We will serve you wholeheartedly!