- Alumina Ring/Alumina Ceramic Ring Suppliers

|

Product number |

GGS-0-A1 |

|

Size |

custom made |

|

Material |

Alumina |

|

Purity |

99.7,99.5,99,95 |

∗The specifications in the table above are typical for oxidized rings. We can customize advanced ceramics in different sizes according to the drawings you provide.

GORGEOUS Supports Full-Process Customization of Alumina Ring

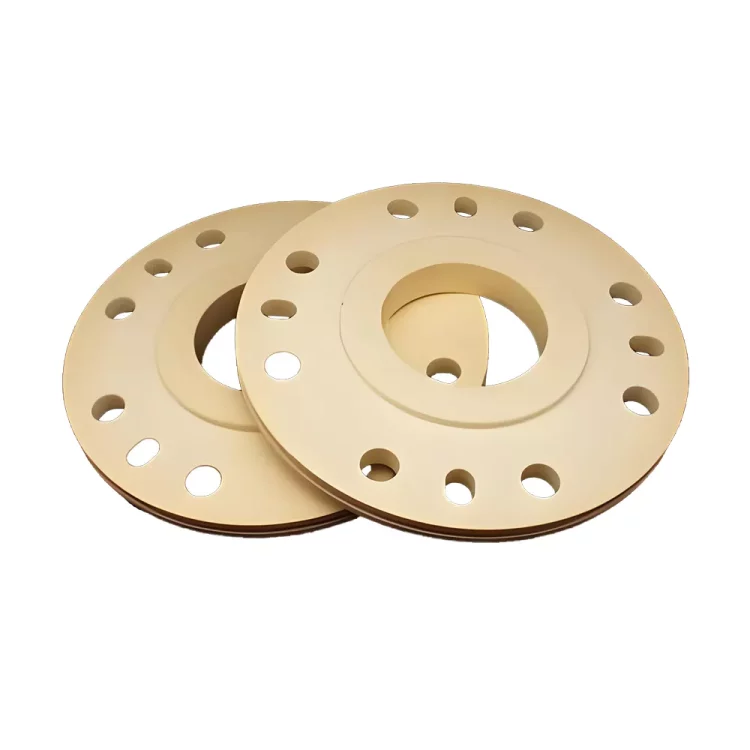

Full Dimension Customization

- Customized by drawings/samples

- Customizable size range reference: Φ1mm-Φ500mm (supports non-standard design, please consult for extra-large items)

- Tolerance control: ultra-high precision ±0.005mm

- Structural customization: through hole/blind hole/step hole/special-shaped hole array

Aluminum oxide ring size reference based on common industry size standards(Standard* dimensions are for high frequency requirements)

|

|

Outer Diameter(mm) |

High(mm) |

Aperture(mm) |

|

Electronic insulation |

5-50(common 18, 24*, 33) |

1-10 (3, 4, 10 are common) |

2-20 (through hole/blind hole) |

|

|

Outer Diameter(mm) |

High(mm) |

Aperture(mm) |

|

Semiconductor Equipment |

10-100 (common 50*, 80) |

10-50 |

5-30 (high precision ±0.01mm) |

![]()

|

|

Outer Diameter(mm) |

High(mm) |

Aperture(mm) |

|

Chemical Filler |

16-80* (six-wing ring/Raschig ring) |

16-85 |

6-40(Porous structure) |

|

|

Outer Diameter(mm) |

High(mm) |

Aperture(mm) |

|

Mechanical Seal |

20-200(common 60*, 120) |

10-60 |

10-100 (precision grinding) |

|

|

Outer Diameter(mm) |

High(mm) |

Aperture(mm) |

|

Energy (fuel cells) |

30-150 |

5-30(Thin wall ring) |

15-80 (porosity controllable) |

If the following sizes cannot meet your needs, we can provide you with customized services, please be sure to contact us!

Manufacturing Technology

- Molding process: dry pressing, isostatic pressing, injection molding

- Polishing level: mirror (Ra≤0.05μm)/matt/sandblasting

- Coating process: vacuum aluminum plating/chemical nickel plating/metallization

- Laser processing: laser marking

Quality Inspection

- List of testing equipment:Keyence tester IM8020, LS-909E laser particle size analyzer, metallographic microscope, hardness tester, withstand voltage tester, insulation resistance tester, flat crystal tester, helium mass spectrometer leak detector, video microscope, Mitutoyo SJ201 surface roughness tester, secondary element tester, three-dimensional coordinate measuring machine

- Quality assurance standard: in accordance with ISO 647-1/GB/T 5593

Introduction of Alumina Ceramic Ring

Alumina ceramic rings are round ceramics made from alumina (Al2O3) through various processing techniques. Our Alumina ring has super high wear resistance and corrosion resistance.

We provide customized services for you based on the drawings you provide. During the customization process, we have a professional team to solve your doubts 24 hours a day. The process of customizing products is transparent and visible. If you have any needs, we can report the customization progress to you in real time.

If you need to customize high-quality Alumina rings, please be sure to contact us. We can provide you with a different service experience.

Superior Production Technology of Alumina Rings

We pay attention to the processing of products, and we strive for perfection in every processing step.

In the process of processing alumina ceramic rings, we grind alumina into submicron (nano) level powder. After actual measurement, the particle size of alumina after sintering can be less than 5 microns. Alumina ceramic rings are composed of these tiny particles. There are almost no pores in the ceramics we produce, and the density is about 3.9 g/cm3 , which creates excellent mechanical strength of alumina rings.

Usage Classification of Alumina Rings

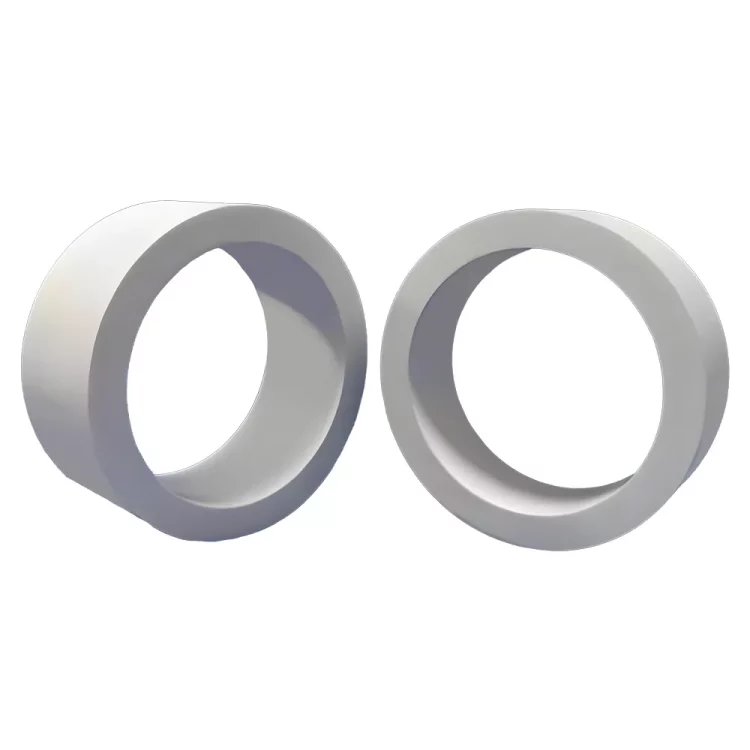

There are many types of alumina ceramic rings, which are more specifically divided into sealing rings, insulation rings, wear-resistant rings, support rings, etc.

🔷 Sealing ring: Sealing ring is mainly used in equipment that requires tight sealing. Our alumina ceramic ring is resistant to high temperature (withstanding high temperature above 1600℃), with simple appearance design and excellent sealing effect, which can keep your equipment in a tight sealing environment.

🔷 Insulating ring: Alumina has excellent electrical insulation. Our alumina insulating ring is designed with special cuts and functions, which can be cut into suitable equipment, provide excellent electrical insulation performance, effectively prevent current leakage, and protect your electrical equipment.

🔷 Wear-resistant ring: The biggest feature of alumina wear-resistant ring is high hardness and strong wear resistance (alumina has a hardness comparable to diamond). The alumina wear-resistant ring we produce can be used in various harsh high-wear environments with confidence.

🔷 Support ring: Support rings usually have unique shapes and some special additional structures. The additional structure can provide good support. Our alumina support rings can be well used in machinery or support structures.

How to Choose Alumina Ring with Appropriate Purity

Normally, the higher the purity, the better the performance of the alumina ring,The common alumina purity range is 92~99.9. We can customize alumina ceramics of various purity and sizes for you.

- 95% alumina rings have low cost, moderate hardness and strength, and are suitable for medium-strength scenarios, such as general wear-resistant parts.

- 99% alumina rings have a high hardness and can be used in higher-intensity application scenarios, such as chemical equipment that requires little chemical corrosion, or electronic devices and high-temperature furnaces.

- Alumina ceramics with 99.5% or above have extremely high hardness and strength, as well as excellent electrical insulation and high temperature resistance. Can be used in high-end electronic devices and precision medical equipment.

- Ultra-pure alumina is an alumina ceramic with a purity >99.9%. This ceramic has almost no impurities and has excellent mechanical properties and chemical stability. It is used for high-end technology research and scientific experiments, such as semiconductors, optical instruments and nuclear industrial manufacturing.

Alumina Ring Material Parameters

| Property | Unit | AL2O3 99.7 | AL2O3 99.5 | AL2O3 99 | AL2O3 95 |

| Purity | — | 99.7% | 99.5% | 99% | 95% |

| Density | g/cm3 | 3.92 | 3.9 | 3.8 | 3.7 |

| Bending Strength | MPa | 375 | 370 | 340 | 304 |

| Compressive Strength | MPa | 2450 | 2300 | 2250 | 1910 |

| Elastic Modulus | GPa | 380 | 370 | 330 | 330 |

| Fracture Toughness | MPam1/2 | 4.5 | 4.3 | 4.2 | 3.8 |

| Hardness | HRA | 91 | 91 | 90 | 89 |

| Vickers Hardness | HV1 | 1600 | 1550 | 1450 | 1400 |

| Thermal Expansion Coefficient | 10- 6 K-1 | 7.8 | 7.8 | 7.7 | 7.5 |

| Thermal Conductivity | W/mk | 32 | 32 | 25 | 25 |

| Thermal Shock Stability | △T.℃ | 220 | 220 | 200 | 200 |

| Maximum Operating Temperature | ℃ | 1750 | 1750 | 1700 | 1500 |

| Volume resistance at 20℃ | Ω·cm | 1015 | 1015 | 1014 | 1014 |

| Dielectric Strength | KV/mm | 22 | 20 | 16 | 15 |

| Dielectric Constant (room temperature) | / | 10 | 11 | 11.5 | 11 |

| MHz Dielectric Loss Factor | tan δ | 1×10-3 | 1×10-3 | 3×10-3 | 3×10-3 |

∗The data in the above table are obtained by testing under specific conditions, and the data may be different under different test conditions. The properties of custom alumina parts will vary depending on the purity and process selected. We can customize the alumina ceramic ring products you require based on the drawings you provide.

Aluminum Oxide Ring Uses:

Alumina rings are widely used in various fields.

- Insulation materials

- Baseboard materials

- Bearing seals

- Laboratory equipment

- Thermal protection materials

- Structural materials

- Induction heating elements

- Liquid handling equipment

Why Choose Us?

GORGEOUS has 15 years of experience in advanced ceramic production. Our factory has obtained ISO 9001:2015 quality management certification and IATF 16949:2016 automotive industry quality management system certification. This means that we can provide you with higher quality products and services!

Our goal!

✅ Finished product qualification rate ≥ 95%

✅ On-time delivery rate ≥ 90%

✅ Customer satisfaction ≥ 90%

GORGEOUS always guarantees the quality of your finished products, from raw materials to parts, from products to projects, we pay attention to every detail, solve all problems encountered in the cooperation process, and always develop new materials and new processes!

▪️ We can conduct manufacturing design (DFM) review for all your projects

▪️ Contract and purchase order review

▪️ Production capacity and production plan review (PMC)

▪️ Incoming raw material inspection

▪️ Sample and process inspection (IPQC)

▪️ Control of non-conforming products and implementation of corrective and preventive measures

▪️ Required final inspection and test reports and certificates (OQC)

▪️ Two customer satisfaction surveys per year, striving to exceed customer expectations

Package

We carefully package each product for you to prevent the goods from being damaged during transportation. We ensure that the aluminum oxide rings delivered to you are of high quality and complete.