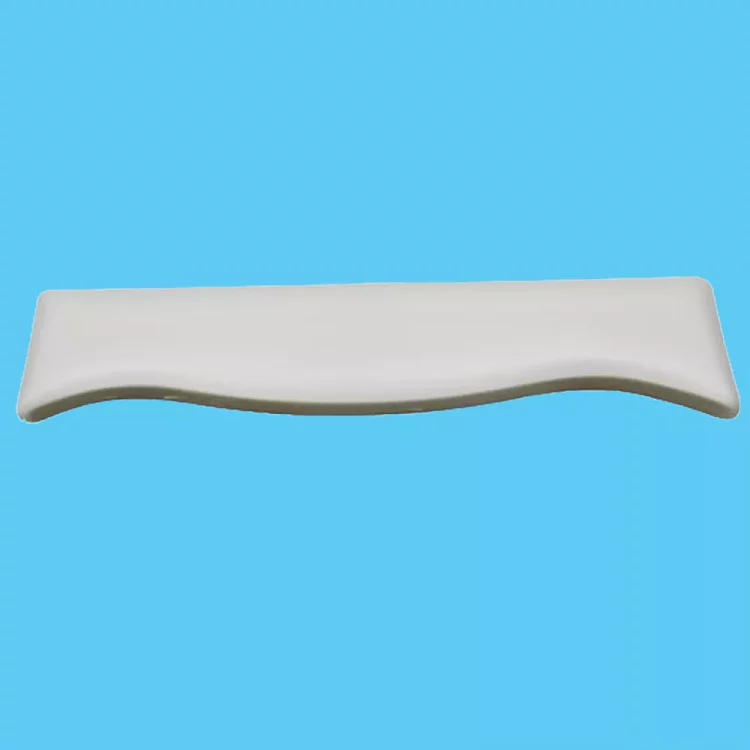

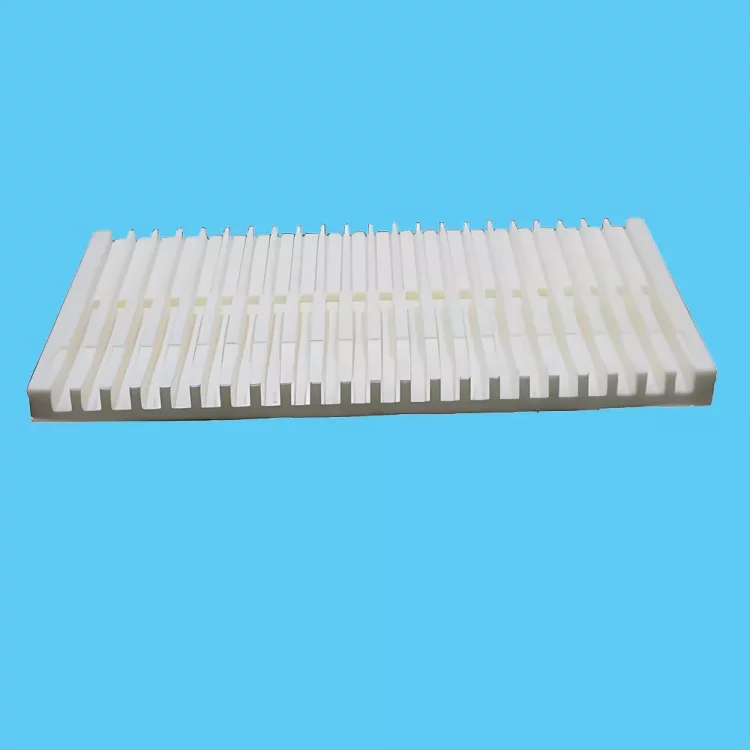

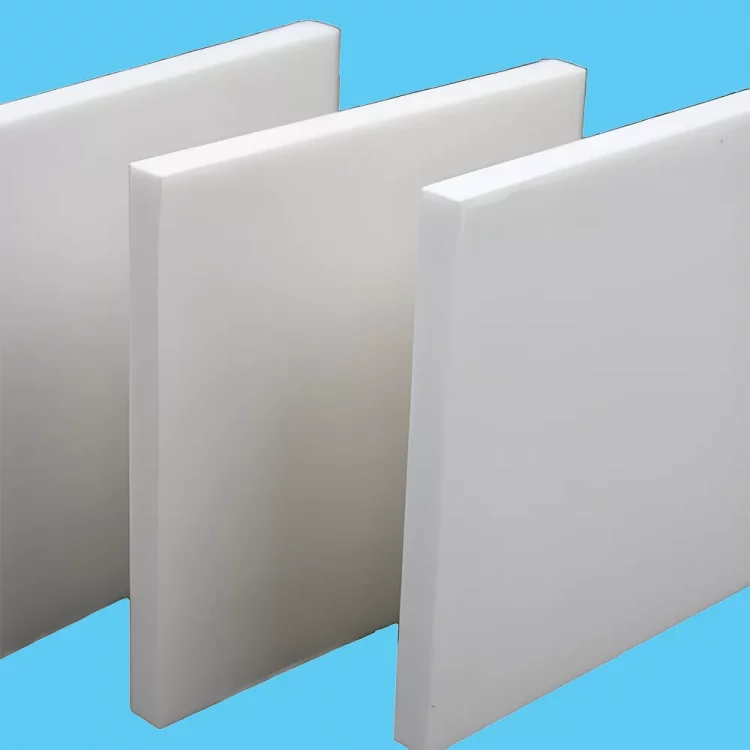

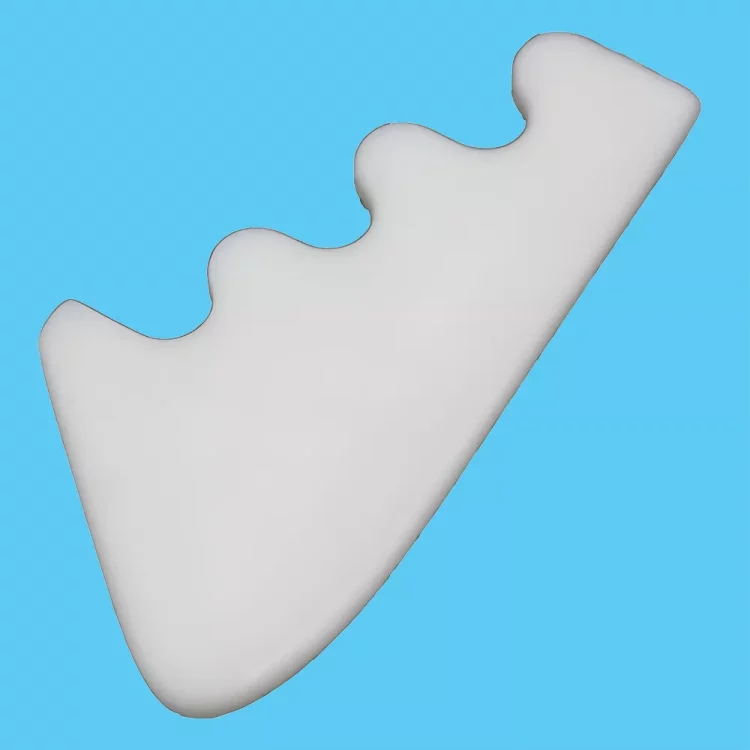

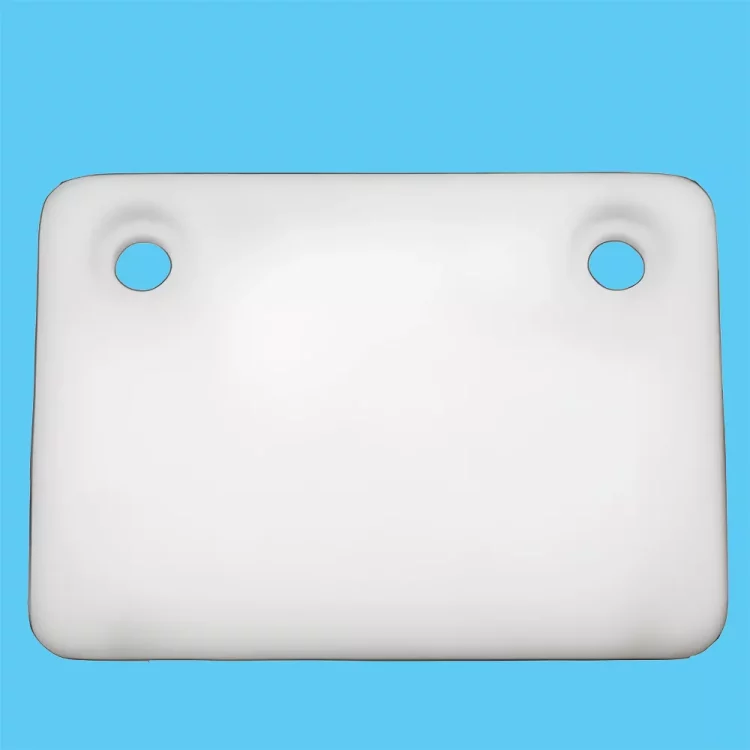

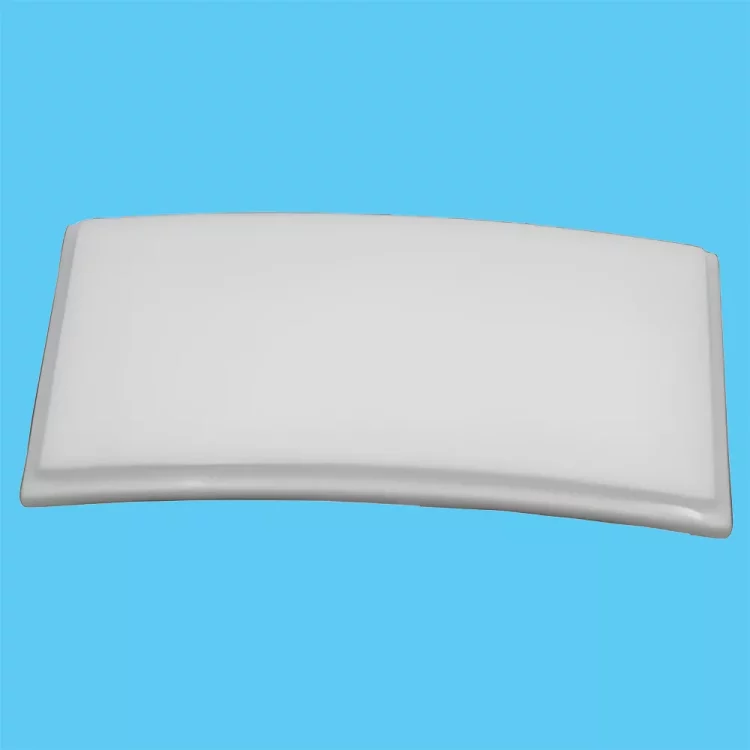

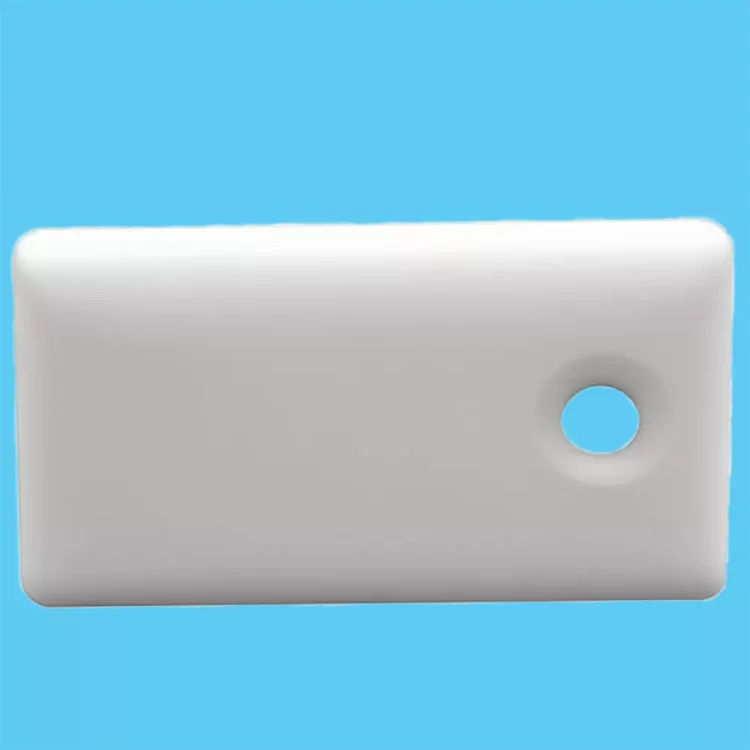

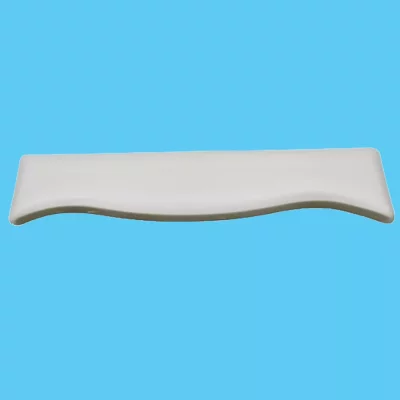

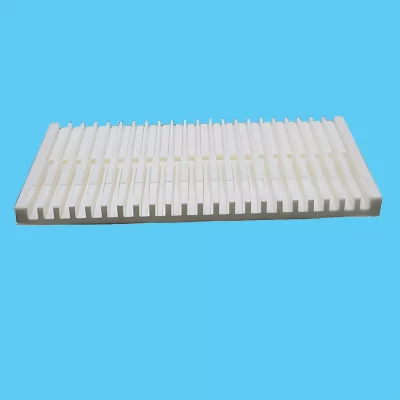

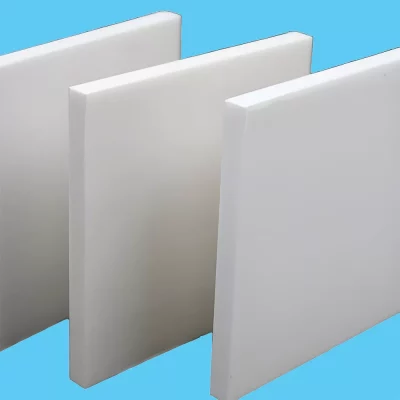

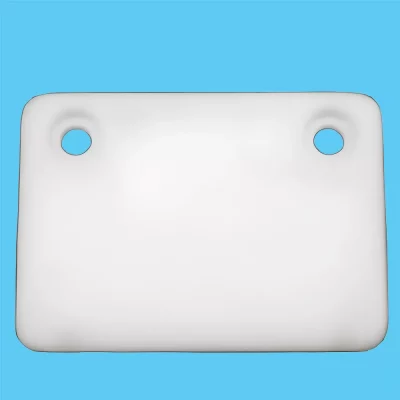

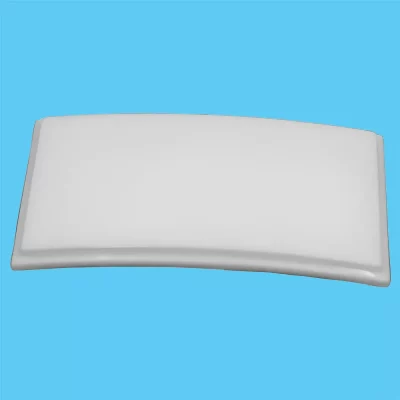

Alumina Plate,Alumina Ceramic Plate,Al2O3

Alumina plates are made of aluminum oxide. We use high-quality alumina as raw material to make advanced ceramics, and grind the alumina powder to the sub-micron (nanometer) level, so that there are basically no voids in the material, and its density is about 3.9g/m3 . Alumina ceramics have superior properties. Ceramic plates have high temperature resistance, high hardness, and strong wear resistance, and can be used in industrial machinery scenarios. At the same time, its electrical insulation and corrosion resistance are also excellent, and it also has many uses in the chemical industry.

Main parameters of alumina ceramics

|

project |

condition |

Performance parameters |

unit |

|

|

95 |

99 |

|||

|

Bulk density |

– |

≥3.65 |

≥3.85 |

g/cm3 |

|

Air tightness |

– |

qualified |

qualified |

|

|

Flexural strength |

– |

≥280 |

≥300 |

|

|

Average linear expansion coefficient |

25℃~500℃ |

7~7.5×10-6 |

7~7.5×10-6 |

1/K |

|

25℃~800℃ |

7~7.5×10-6 |

7~7.5×10-6 |

1/K |

|

|

Dielectric constant |

1MHz |

9~10 |

9~10.5 |

– |

|

(10±0.5)GHz |

||||

|

Dielectric loss tangent |

1MHz |

≤3×10-4 |

≤4×10-4 |

– |

|

(10±0.5)GHz |

≤6×10-4 |

≤6×10-4 |

– |

|

|

Volume resistivity |

25℃ |

≥1×10-14 |

≥1×10-14 |

Ω.cm |

|

300℃ |

≥1×10-11 |

≥1×10-11 |

||

|

Breakdown strength |

D.C |

≥20 |

≥30 |

KV/mm |

|

Average grain size |

– |

10~20 |

8~16 |

μm |

*The above table only shows typical properties of alumina materials under specific conditions. The properties of custom alumina parts will vary depending on the purity and process selected. We can provide custom alumina ceramic plate services to your specifications.

Alumina plate uses:

- Circuit Board:Alumina ceramic plates can be used as substrates for circuits and are suitable for high frequency and high efficiency applications.

- Electrical Insulation Board:Used in insulating components in electrical equipment, such as insulating panels and partitions, etc.

- Wear Plate:Aluminum oxide is highly wear-resistant and can be used in wear-resistant parts of mechanical equipment, such as liners, guide rails and slide plates.

- Precision Instrument:Aluminum oxide can make high-precision mechanical parts and instrument base plates, etc.

- Laser Equipment Parts:Aluminum oxide can be made into optical element support plates and reflector substrates in laser equipment.

- Fiber Optic Equipment: Support structures and connector substrates used in fiber optic communications equipment.

Why choose us?

We have a professional advanced ceramic production factory with more than 10 years of R&D experience;

We only produce high quality advanced ceramics, using the best raw materials and equipment during manufacturing;

We conduct product inspection strictly. For high-precision ceramic parts, we achieve the smallest and most reasonable tolerances;

A group of R&D teams with rich professional knowledge are at your service at any time;

We enjoy a good reputation at home and abroad and are appreciated by many partners;

There is no minimum order quantity limit for some products, you are welcome to call us for inquiries;

If you need free alumina ceramic plate samples, please contact us.

Package

Gorgeous carefully packages each piece of advanced ceramic products to prevent the goods from being damaged during transportation. We ensure that the goods delivered to you are of high quality and complete.