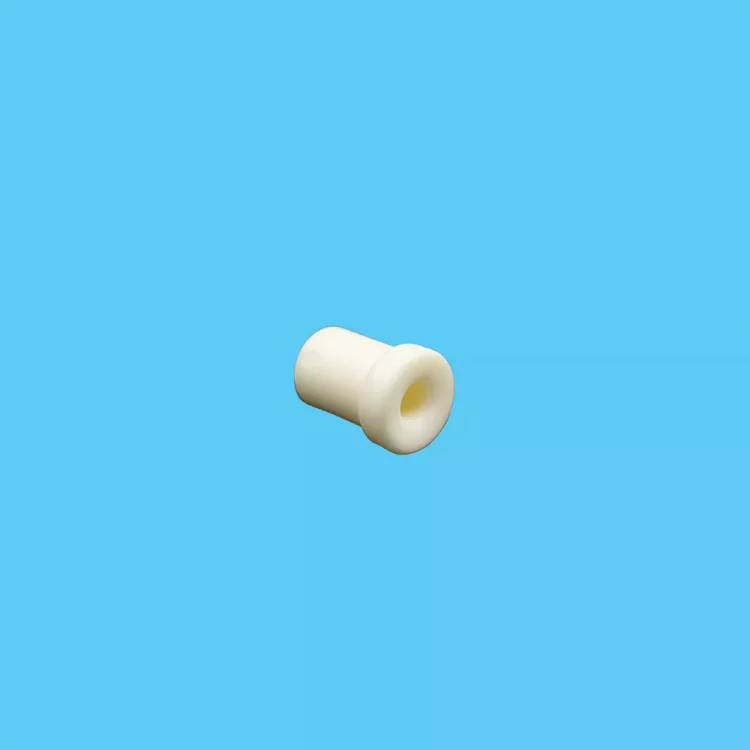

Alumina Bushing , Aluminum Oxide Bushing , Al2O3

Alumina Bushing is a durable ceramic bushing made of alumina with various excellent properties. You can use it for bearings in the mechanical industry, insulation parts in the electronic industry, etc.

We provide customized services for you, with various purities and sizes, and we also have many other materials for you to choose from!

Superior Performance of Alumina Bushings

High temperature resistance - withstands temperatures up to 1600°C

Abrasion resistance - excellent wear resistance

Electrical insulation - effectively blocks current to protect precision parts

Attached is the performance parameter table of alumina for your reference

|

project |

condition |

Performance parameters |

unit |

|

|

95 |

99 |

|||

|

Bulk density |

– |

≥3.65 |

≥3.85 |

g/cm3 |

|

Air tightness |

– |

qualified |

qualified |

|

|

Flexural strength |

– |

≥280 |

≥300 |

MPa |

|

Average linear expansion coefficient |

25℃~500℃ |

7~7.5×10-6 |

7~7.5×10-6 |

1/K |

|

25℃~800℃ |

7~7.5×10-6 |

7~7.5×10-6 |

1/K |

|

|

Dielectric constant |

1MHz |

9~10 |

9~10.5 |

– |

|

(10±0.5)GHz |

||||

|

Dielectric loss tangent |

1MHz |

≤3×10-4 |

≤4×10-4 |

– |

|

(10±0.5)GHz |

≤6×10-4 |

≤6×10-4 |

– |

|

|

Volume resistivity |

25℃ |

≥1×10-14 |

≥1×10-14 |

Ω.cm |

|

300℃ |

≥1×10-11 |

≥1×10-11 |

||

|

Breakdown strength |

D.C |

≥20 |

≥30 |

KV/mm |

|

Average grain size |

– |

10~20 |

8~16 |

μm |

*The above data are parameter data measured under normal conditions and are for your reference only.

Alumina Bushing Application

Wear protection – protect some key parts of equipment from wear and tear, can be used for some wear-prone purposes.

Corrosion protection – used as the lining of reactors, desulfurization devices, pipelines, and pump bodies to prevent corrosion.

Insulator – in electrical packaging, it plays an insulating role to prevent the conduction of current.

Why Choose Us?

We have our own production plant and have more than 15 years of experience in producing advanced ceramics. You can rest assured to place your order with us.

We have a variety of advanced and superior equipment and use high-quality alumina powder as raw material, which can definitely meet your order needs!

If you have any needs, please contact us immediately!

packaging

We will carefully package your products and ensure that the products delivered to you are intact!

You don’t have to worry about the products you receive being damaged. If the products are damaged during transportation, we will compensate you.

After-sales

We attach great importance to our customers’ after-sales experience and we look forward to long-term cooperation with you. You don’t have to worry about after-sales problems not being resolved in time. Our team is ready to solve any problems you encounter at any time!

FAQ.

- How does alumina compare to other materials?

Like many other ceramic materials, alumina has strong hardness and wear resistance, and can withstand high temperature and high pressure. At the same time, the price of alumina is cheaper.

- What information should I provide to get a quote?

You just need to provide us with customized basic information and our professionals will guide you.

- How long do your aluminum oxide bushings last?

Our products undergo rigorous quality testing after production. According to our customer feedback, ceramic bushings can be used for many years as long as they are properly maintained.