Introduction — The Strength Behind Innovation

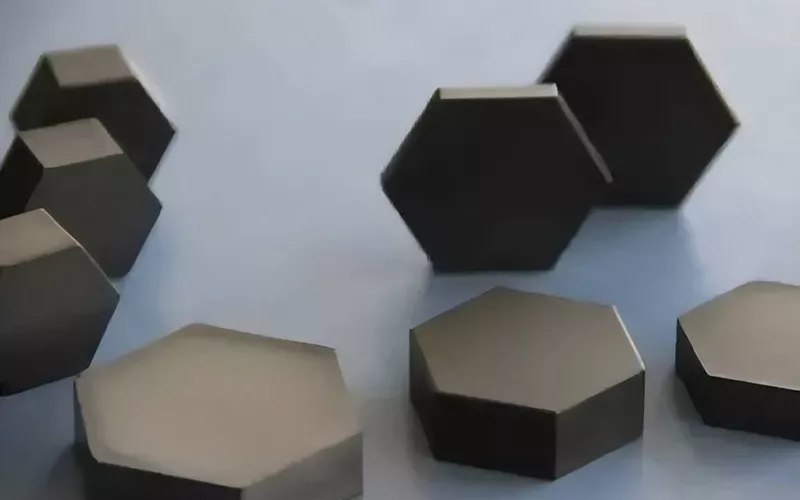

Boron carbide ceramics are a new class of materials that have achieved tremendous success in industrial and defense applications and are among the hardest materials on Earth.

This lightweight ceramic, second only to diamond in hardness, combines exceptional strength with low density and chemical resistance. From armor to abrasive tools to nuclear shielding, boron carbide ceramics have quietly become a cornerstone of modern technology.

In this article, we’ll explore the unique characteristics of boron carbide ceramics—its composition, properties, manufacturing processes, and its wide range of applications across various industries.

What Is Boron Carbide Ceramic (B₄C)?

So, is boron carbide a ceramic? Yes—it’s a non-oxide ceramic composed primarily of boron and carbon atoms, forming a rhombohedral crystal structure that possesses exceptional hardness and strength.

Boron carbide (B₄C) was originally used as an abrasive and was first synthesized in the 19th century. Later, researchers discovered its neutron-absorbing and high-stress resistance properties, making it an ideal material for boron carbide ceramic armor and nuclear control rods.

To be precise, boron carbide is a ceramic, not a metal or a polymer. Therefore, whenever someone asks, “Is boron carbide a cermet or a polymer?” the answer is clear: boron carbide is a ceramic compound, scientifically classified as a boron carbide B₄C ceramic.

Key Properties of Boron Carbide Ceramics

Mechanical Properties

Among many high-strength ceramics, boron carbide ceramics stand out. With a Mohs hardness of 9.3, it’s second only to diamond and cubic boron nitride. This high strength-to-weight ratio makes it an indispensable material for ballistic and personal protection systems.

Boron carbide body armor, made from silicon carbide, is lightweight and highly rigid, making it more comfortable and effective than traditional metal-based body armor. Furthermore, boron carbide ceramics offer superior ballistic resistance compared to Kevlar fibers.

Thermal and Electrical Properties

Boron carbide ceramics combine excellent thermal resistance and electrical insulation. Their low thermal expansion and high thermal stability enable them to operate at extremely high temperatures—a key reason why boron carbide is highly valued in aerospace and energy systems.

Chemical Resistance

Chemically, boron carbide ceramics are resistant to acids, oxidation, and most corrosive agents. This durability ensures long-lasting use even in abrasive or chemically aggressive environments, making it an ideal choice for boron carbide ceramic tiles, industrial nozzles, and reactor components.

How Boron Carbide Ceramics Are Made

Synthesis of Boron Carbide Powder

Boron carbide (B₄C) ceramics are synthesized from high-purity boron oxide (B₂O₃) and carbon. Fine boron carbide powder is produced through either a fusion process or a magnesium thermal reduction process.

Both processes are common production methods for high-performance boron carbide ceramic manufacturers in China. Leveraging advanced production equipment, China provides high-performance boron carbide (B₄C) ceramics to the global market.

Molding and Sintering

During the production process, the powder is mixed with sintering aids (such as alumina or chromium) to enhance density. Subsequently, the powder is formed through hot pressing, pressureless sintering, or spark plasma sintering (SPS) to produce highly dense, low-porosity boron carbide ceramic armor plates.

Finishing and Quality Control

Finished parts are precision-machined to meet stringent tolerances and undergo a variety of boron carbide ceramic property tests, including hardness, fracture toughness, and density. Several boron carbide ceramic material factories in China are supplying high-quality components to the defense and aerospace industries.

Applications of Boron Carbide Ceramics

Armor and Ballistic Protection

Boron carbide ceramic armor and body armor are primarily used in military vehicles, helmets, and bulletproof vests. Their lightweight design helps reduce soldier fatigue while providing reliable protection against high-velocity projectiles.

Advanced systems such as boron carbide rolled homogeneous armor (RHA) and optimized RHA thickness have been extensively researched to enhance performance.

Abrasives and Cutting Tools

Boron carbide ceramics can be used in grinding wheels, nozzles, and polishing tools, outperforming many ceramic materials and even boron carbide alternatives. The extremely high wear resistance of boron carbide cermet tools ensures their high efficiency and long life.

Nuclear and Energy Applications

Boron carbide ceramics have a high neutron absorption cross-section, making them an ideal material for nuclear reactor control rods. They help regulate fission reactions safely and efficiently—a core reason for boron carbide’s continued popularity as a ceramic material in the energy sector.

Aerospace and Defense Systems

In the aerospace sector, boron carbide (B₄C) metal-polymer ceramic composites are used to manufacture lightweight and durable components such as nozzles, shields, and high-friction parts. The boron carbide-ceramic metal matrix structure provides improved heat dissipation and mechanical stability at high altitudes.

Challenges and Future Prospects

While boron carbide ceramics offer numerous advantages, they still face challenges such as brittleness and difficulty in processing. Research is currently underway to improve their fracture toughness through composite reinforcement and nanostructuring techniques, such as hot-pressing boron carbide ceramics.

China has become a core global manufacturing hub for boron carbide ceramics. Leveraging its boron carbide ceramic performance factories and boron carbide ceramic material suppliers, China offers competitive pricing and innovative capabilities in material processing to the global market. As various industries pursue stronger, lighter, and more sustainable materials, the Chinese wholesale market for boron carbide ceramic performance is poised for significant growth opportunities.

Conclusion

From boron carbide armor plating to nuclear shielding, boron carbide (B₄C) ceramics have become an indispensable material in industries demanding extreme durability and lightweight design.

So, why is boron carbide a ceramic? Because it embodies the hallmarks of advanced ceramics—hardness, toughness, and innovation. As technology advances, boron carbide ceramics will continue to redefine performance standards in defense, aerospace, and industrial engineering.

As a leading ceramic wholesaler, GORGEOUS offers customers the highest-quality boron carbide ceramics, custom-made to meet diverse application requirements.

FAQ

1.What are Boron Carbide Ceramics?

Boron carbide—chemical formula B₄C—is a non-oxide ceramic with extremely high hardness, second only to diamond and cubic boron nitride (CBN).

It is known for its lightweight, high hardness, wear resistance, and corrosion resistance. It is frequently used in bulletproof armor, nozzles, grinding wheels, and the nuclear industry.

2.Is boron carbide a metal, ceramic, or polymer?

Boron carbide is a ceramic material that belongs to non-metallic inorganic compounds. It is neither a metal nor a polymer.

3.Why is Boron Carbide called “Black Diamond”?

Because its Mohs hardness is close to 9.5 and its Vickers hardness is between 30–38 GPa, which is almost comparable to diamond, it is called “black diamond”.