Product Description

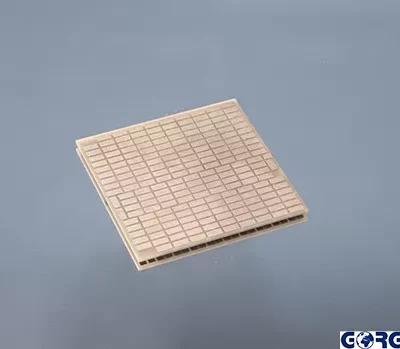

GORGEOUS High Vacuum Application Metallized Ceramic Tubes For Feedthrough

Metallization of Ceramic

So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing. A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that has a different coefficient of thermal expansion.

A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering.

The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

Main Features

1) High-intensity sealing, high air-tightness, high reliability, good heat resistance

2) Excellent insulation performance and high temperature resistance

3) Good mechanical , electrical and thermal conductivity

2) Excellent insulation performance and high temperature resistance

3) Good mechanical , electrical and thermal conductivity

4) Great bonding strength

5) Refractory Formulation Molybdenum-Manganese (MoMn)

6) Can be coated with silver, tin and other metal technology

7) Widely used for all electric products and electric heating products