GORGEOUS CERAMICS (GGS) ALN Heater Heat dissipation expert in Wafer Processing

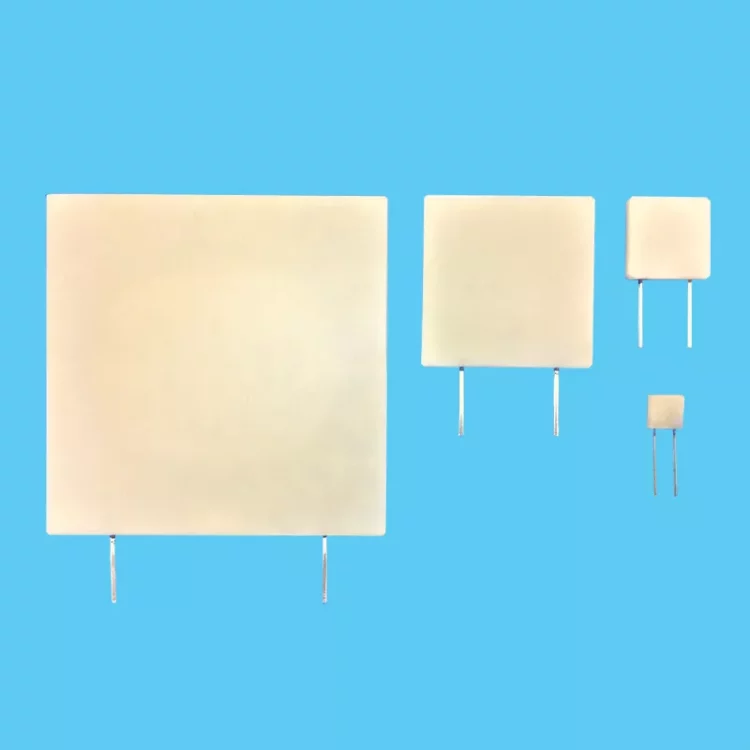

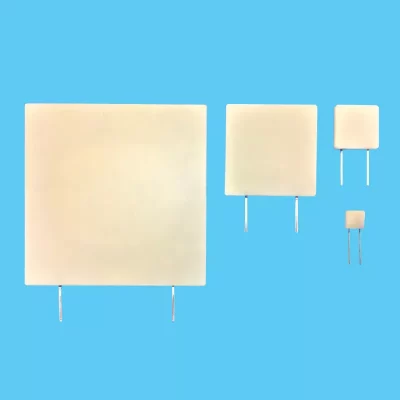

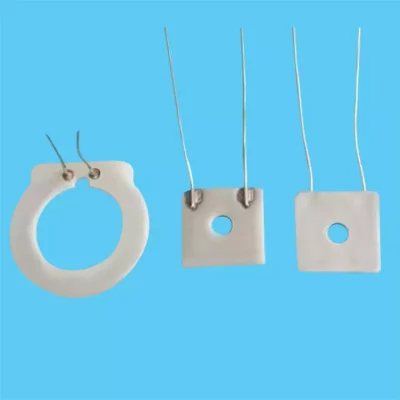

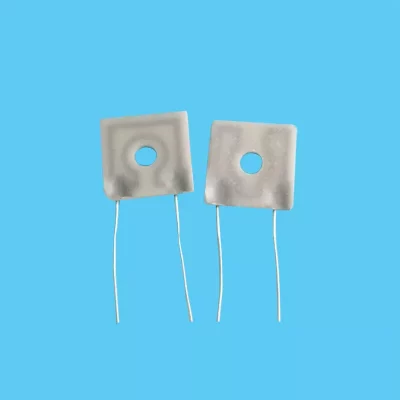

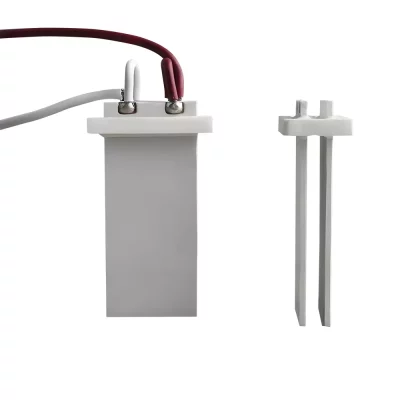

ALN Heater is one of our featured products, combining the best of both worlds: ceramics and metal. This innovative design, achieved through metallization, makes it the perfect solution for your various semiconductor and electronic equipment manufacturing needs.

We utilize high-performance aluminum nitride material to endow the ALN Heater with exceptional thermal uniformity and corrosion resistance, making it ideally suited for wafer processing. Additionally, we offer customized services to cater to your diverse needs, helping you improve production and processing efficiency while enhancing the quality of your products.

Unveiling the Features of the ALN Heater:

- Outstanding Temperature Field Uniformity:

Our ALN Heater is crafted from high thermal conductivity aluminum nitride material, ensuring exceptional temperature field uniformity across a wide temperature range (up to 790 degrees Celsius). This translates to consistent temperature during wafer processing, ultimately improving product yield and production processing speed.

- Space-Saving Design:

Through co-sintering the resistance heating element and the block RF electrode within the ALN ceramic, we achieve a compact and efficient design for the ALN Heater. This not only reduces the overall size of your equipment but also enhances heating efficiency and heat transfer speed, saving valuable production space.

- Excellent Corrosion Resistance:

The aluminum nitride ceramic heaters boasts outstanding resistance to corrosion caused by halogen gas and oxidizing environments. This allows it to maintain long-term stability in high-temperature and continuous operation settings, extending the service life of your equipment and reducing the cost of routine operation and maintenance.

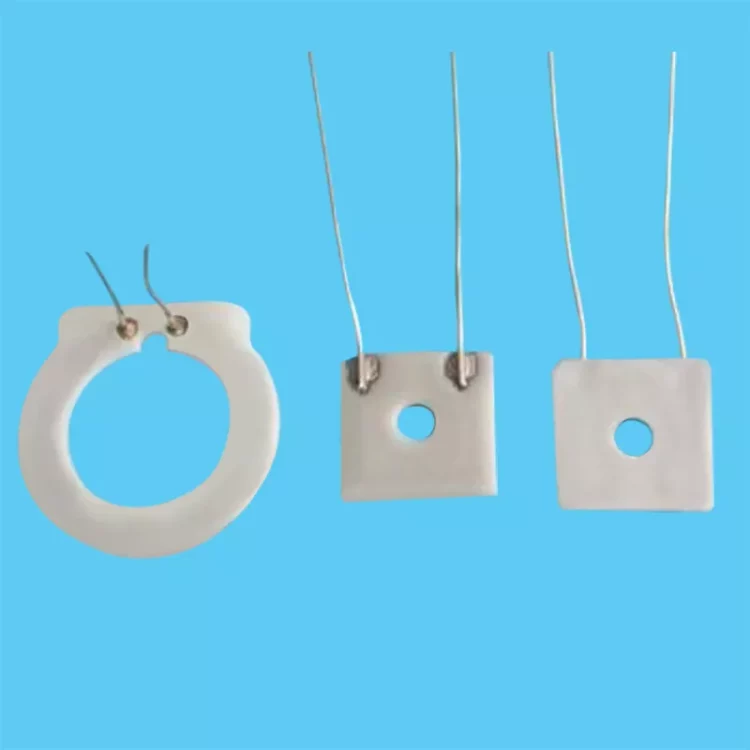

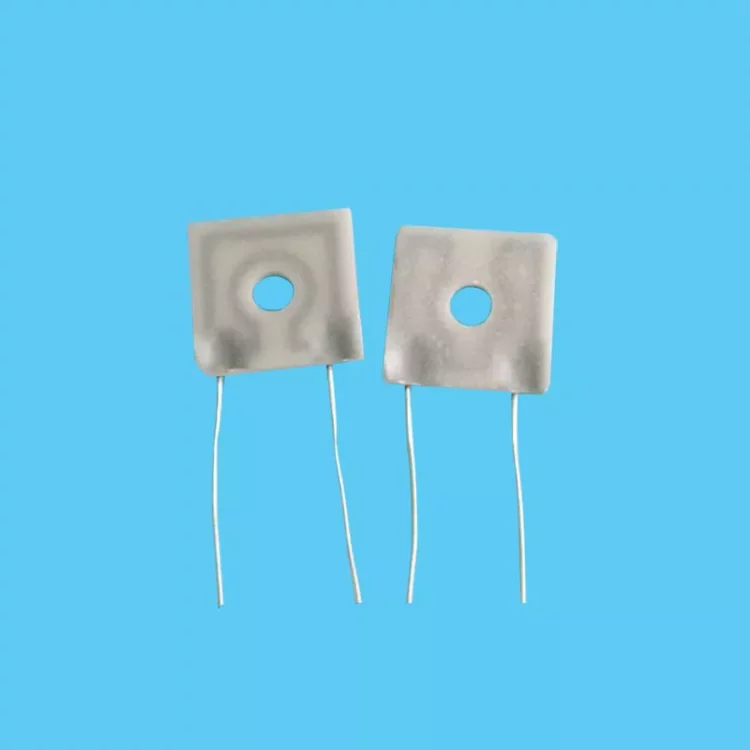

- Design Pending Clamping Function for Wafers:

By sintering the RF electrode with the ceramic plate, the ALN Heater integrates the functionality of an electrostatic chuck electrode for wafer clamping. This feature simplifies your production process, leading to improved production speed and efficiency – a highly valued benefit in wafer processing.

- Customized Solutions:

We understand that every production process has unique requirements. That’s why we provide customized ALN Heater solutions to meet your diverse needs. Whether it’s size, power requirements, or electrode configuration, we can tailor the product to perfectly integrate with your specific production process.

ALN Material Properties Data:

The following table summarizes the key properties of AlN material:

| Name | Purity [%] | Density [g/cm³] | Volume Resistivity [Ωcm] (Room Temp.) | Thermal Conductivity [W/m·K] (Room Temp.) | Thermal Expansion Coefficient (1000℃) | Strength [MPa] (Room Temp.) | Young’s Modulus [GPa] (Room Temp.) | Dielectric Constant (13.56MHz, Relay) |

|---|---|---|---|---|---|---|---|---|

| AlN/Aluminum Nitride | 95 | 3.3 | >1E+15 | 170 | 5.7 | >300 | 300 | 8.6 |

| AlN/Aluminum Nitride | 97 | 3.31 | >1E+8 ~ +13 | 100 | 5.6 | >300 | 300 | 8.8 |

| AlN/Aluminum Nitride | 99 | 3.32 | >1E+15 | 80 | 5.6 | >250 | 300 | 8.6 |

Experience the GORGEOUS CERAMICS (GGS) Difference:

At GORGEOUS CERAMICS (GGS), we are committed to providing innovative and high-performance solutions for your semiconductor and electronic equipment manufacturing needs. Contact GORGEOUS CERAMICS (GGS) today to discuss your specific requirements and learn more about how the aluminum nitride ceramic heaters can revolutionize your wafer processing efficiency.

- Explore our customized ALN Heater solutions: [Contact GORGEOUS CERAMICS (GGS) for a quote]

- Discover more about GORGEOUS CERAMICS (GGS) and our commitment to excellence: [https://ggsceramic.com]