Aluminum Nitride (AlN) Substrates Supplier - Customized Best Solution

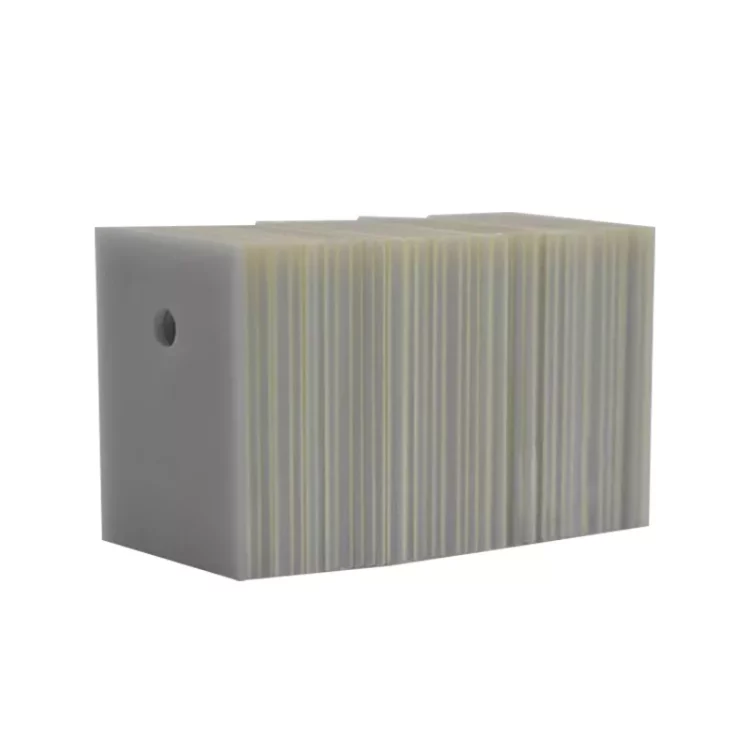

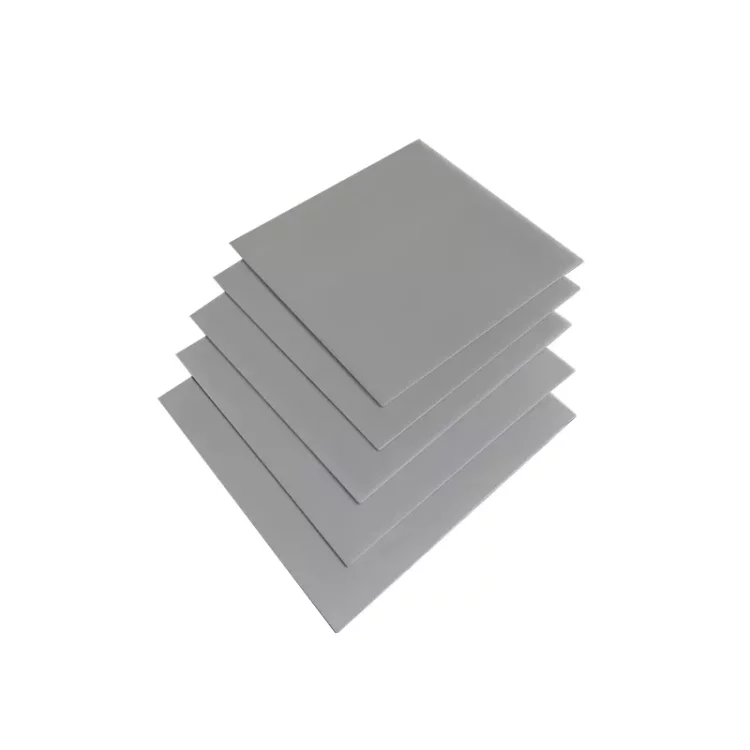

Aluminum nitride (ALN) substrate is a ceramic substrate with excellent thermal and electrical properties, high bending strength (450), and excellent thermal conductivity (170W/mK). In ultra-high power electronic devices, it is an ideal heat dissipation choice for customers, ensuring the stability of electronic devices during operation and effectively reducing the impact of thermal stress on components.

GORGEOUS designs aluminum nitride substrates specifically for power semiconductor components, customizing and providing the best heat dissipation solutions.

Aluminum Nitride (AlN) - Learn more about this material

Key Advantages of ALN Substrates

Aluminum Nitride Substrate Technical Values & Parameters

|

Physical properties |

Electrical properties |

|

Density: ≥ 3.34 g/cm3 |

Dielectric constant at 1 MHz: +/- 8.5 |

|

Ra value: ≤ 0.4 µm |

Dielectric loss factor at 1 MHz: ≤1 (10-3 ) |

|

Color: Grey/Light Brown |

Volume resistivity at 20℃: ≥1014 Ω cm |

|

Maximum temperature: ≥1000℃ (inert gas) |

Dielectric strength: ≥15 kV/mm |

|

Mechanical properties |

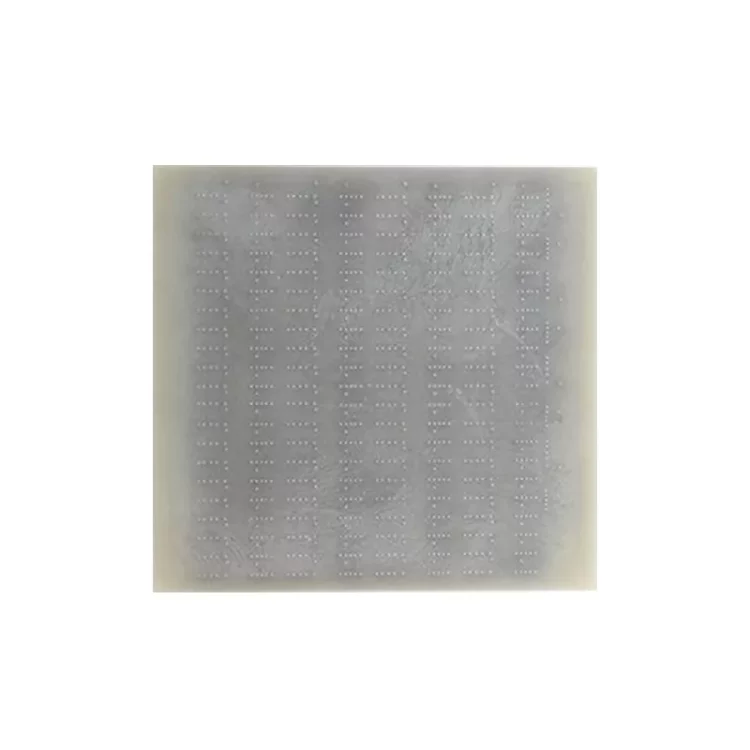

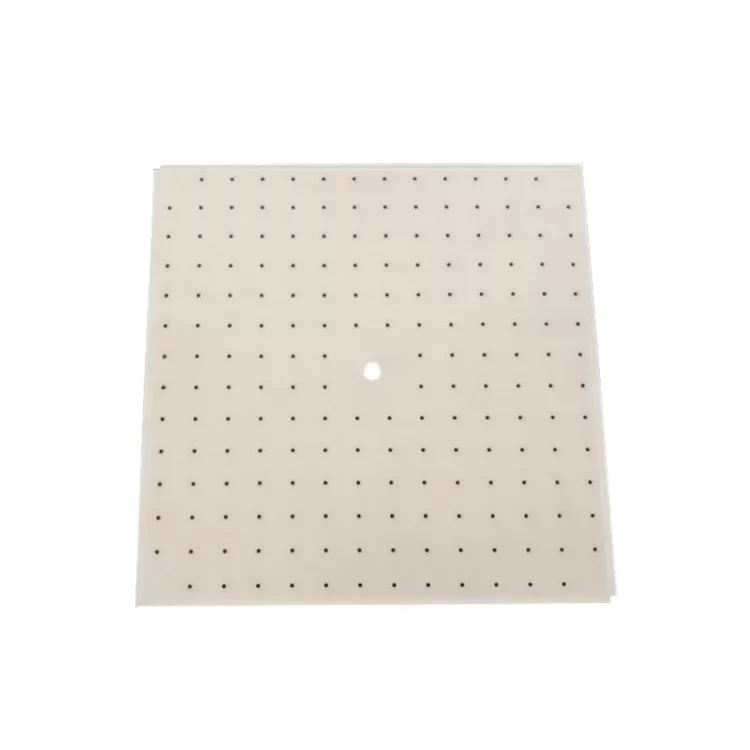

Geometry - Masterplates |

|

Bending strength DR sigma 0 (3 Point Method): ≥450 MPa |

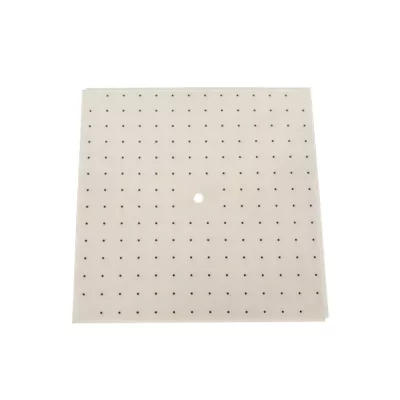

Standard Size: 190 mm × 140 mm (7.5″ × 5.5″), tolerance ±1.0% |

|

Fracture toughness (IF method): ≥3.0MPa*√m |

Thickness Range:0.38 mm to 1.50 mm, tolerance ±10% |

|

Young´s modulus: ≥ 300 GPa |

Warpage/Camber: 0.2% to 0.6% |

|

Thermal properties |

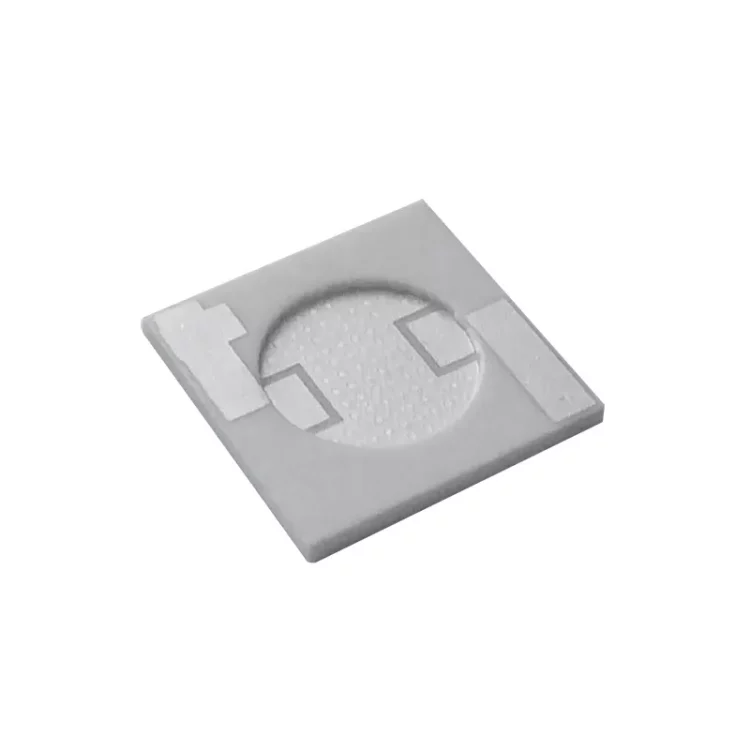

Geometry - Laser Substrate |

|

CTE: 100-800°C: ± 4.8 - 6.2 10-6 /K |

Standard Thickness: 0.635 mm (0.025″) |

|

Thermal conductivity (25℃): ≥170 W/(m·K) |

Length & Width Tolerance: +0.20 mm / -0.05 mm (+0.0079″ / -0.002″) |

|

Specific heat capacity (25°C): 0.72 J/gK |

Application fields of AlN substrate

- IGBT module ceramic heat dissipation substrate

- Laser diode packaging substrate (LD Submount)

- High-frequency communication module (such as 5G power amplifier module)

- LED chip packaging heat sink

- Power semiconductor device (MOSFET, SiC, GaN device) packaging substrate

- Aerospace radar component heat dissipation layer

- Electric vehicle inverter module heat dissipation base

- Microwave/millimeter wave circuit substrate (MMIC)

- High-performance circuit substrate in medical imaging equipment

- High-frequency power module substrate in industrial automation control system

- Optocoupler packaging substrate

- RF power amplifier module substrate

Processing Services

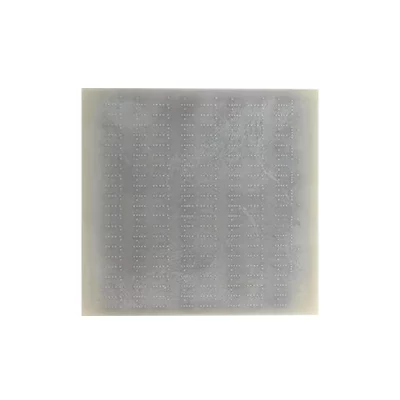

- Metallization processing (thin film, thick film, DBC, AMB, DPC, etc.)

- Machining

- Aluminum Nitride Sputtering Targets

- Polishing/grinding

| Feature | Sputtering Targets | Substrate |

|---|---|---|

| Material Type | Aluminum Nitride (AlN) | High-Purity Aluminum Nitride (AlN) |

| Symbol | AlN | AlN |

| Purity | 99.5% or International Standards | 99%, 99.99% or International Standards |

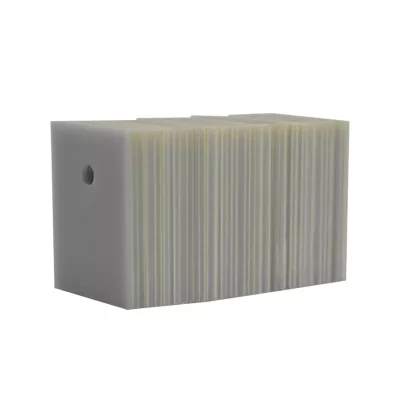

| Shapes | Discs, Plates, Steps (Dia 355mm, Thickness 0.5mm) | Discs, Rectangles, Steps, Plates, Sheets, Rods |

| Custom Shapes & Sizes | Available for quoting | Available for quoting |

| Dimensions | Diameter (355mm), Thickness (0.5mm), Custom-Made | Custom-Made |

Additional Notes:

- Both Sputtering Targets and Substrates are made from high-quality Aluminum Nitride.

- Purity levels can be customized to meet specific requirements.

- A variety of shapes and sizes are available, including custom options.