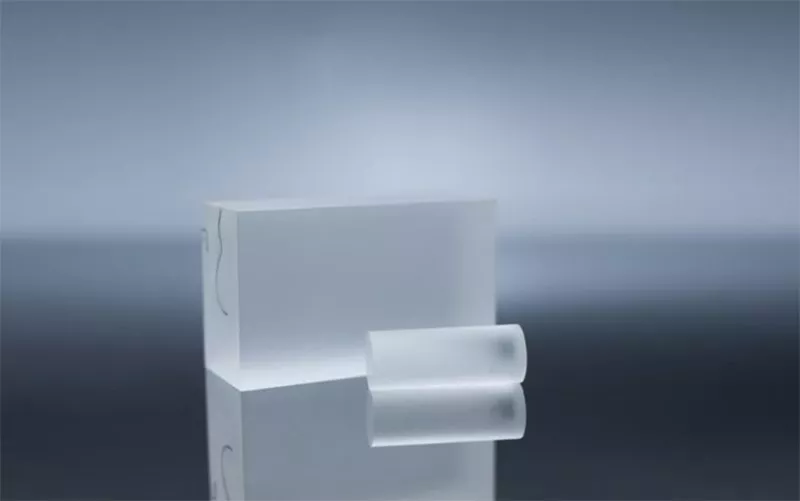

You probably think ceramics can’t be see-through like glass. I used to think that too until I saw my first transparent ceramic sample. These amazing materials look like glass but are much stronger than steel. You get clear metal vision with incredible toughness that regular glass can’t match.

Understanding Transparent Ceramics: What Makes Them Special?

How Can Ceramics Be Clear Like Glass?

Transparent ceramics work the same way as window glass, light is transmitted as it is. When I started working with these materials, I was surprised to see that they are made from common ceramic powders that are usually not transparent.

Transparency requires phenomenal technology. Engineers must keep ceramic particles smaller than rays. When I visited a factory, I heard that a grain of dust would ruin the work for a week.

The manufacturing room is kept cleaner than the operating room of the hospital. Workers wear special suits and masks. If there is contamination, start over from the beginning.

This careful work is rewarded. As a result, a material that can withstand much stronger and extreme heat while being transparent comparable to good quality glass is obtained.

Why Are They Better Than Regular Glass?

During my years working with these materials, I’ve seen some incredible things:

Strength advantages:

-

Four times harder than regular glass

-

Can handle 300-600 MPa of pressure (glass only handles 50-100 MPa)

-

Won’t crack from impacts that would shatter bulletproof glass

-

Can work at temperatures up to 1,600°C (glass melts at 400°C)

“Since we started using transparent ceramics instead of regular glass windows, we haven’t had a single breakage in two years of testing.” Mike Johnson, Test Engineer, Defense Solutions Inc.

You simply can’t get this combination of see-through clarity and super strength with any other material.

Current market: What is happening now?

The Market Is Growing Fast

When I started tracking trends in this industry five years ago, few people had heard the term transparent ceramics. But now, large orders are coming in one after another. A supplier I know has significantly increased production from hundreds to thousands per year. In addition, a friend who runs a ceramics company told me that sales of transparent ceramics have increased three times since 2022. The demand is getting crazy.

I have observed this market carefully. Asia is leading, accounting for about 40% of total sales. China alone increased spending on transparent metal technology by 18% in 2023.

The largest share (about 57%) is occupied by single crystal materials. These are best suited for high-end applications such as military equipment and aerospace.

Latest Company News and Developments

This year, I have tracked some big moves in the industry:

Fraunhofer IKTS established the first European transparent ceramics research center in Germany last August. They invested €2.5 million in this facility. What is noteworthy about this facility is that it can test ideas in the laboratory and then scale up to the actual production process.

Murata Manufacturing launched its latest line of transparent ceramics products in March. I saw samples at the exhibition. These new materials maintain a crystal-like clear view while enduring harsh environments that destroy conventional versions.

Samsung Electronics started adopting transparent ceramics for premium displays. This is worth noting because these materials have finally begun to be used in general consumer products beyond the military and aerospace fields.

Types of Transparent Ceramics: Which One Do You Need?

ALON: The Military Choice

ALON transparent aluminum is what the military uses this transparent metal most. ALON (aluminum oxynitride) creates transparent aluminum. It’s made from aluminum, oxygen, and nitrogen.

ALON features:

-

80 ~ 85% light through

-

Better bulletproof performance than bulletproof glass

-

Can be used in high temperature environments up to 1,200°C

-

40% lighter than normal bulletproof glass

I’ve seen ALON windows on military vehicles. They look just like regular glass but can stop high-powered rifle bullets.

Where you’ll find ALON:

-

Military clear ceramic tint for vehicles

-

Aircraft protection

-

Submarine periscopes

-

High-security buildings

The cost is $10-15 per square inch. That means a 12×12 inch piece costs $1,440-2,160.

“Our ALON windows have taken direct hits and kept our crew safe. Regular glass would have failed on the first shot.” Captain Sarah Mitchell, U.S. Army Vehicle Testing

Transparent Spinel: For Extreme Heat

Most materials crack under pressure, but spinel ceramics also withstand extreme temperatures. From extreme Arctic conditions at -180°C to scorching heat at 1,200°C, these materials continue to function.

What’s special? Magnesium aluminum spinel transmits 87% of light and is excellent in compatibility with infrared cameras. I have used these parts too much, repeated several hundred heating and cooling cycles, but they are still like new ones. No cracks, no clouds, nothing.

Main Uses:

-

Window for missile guidance

-

Satellite Sensor

-

Observation in high temperature environments

-

Laser Equipment

The price of each part varies from $20,000 to $80,000 depending on the application. Last year, the industry raised $40 billion in sales to help this technology solve real problems.

Transparent Alumina: For Electronics

Transparent aluminum ceramics are ideal for electronics. Ideal for LED lighting because it transmits 90% of infrared light.

These materials have excellent thermal conductivity. This helps to cool the electronic components during operation.

Main Uses:

-

High output LED base

-

Medical Device Window

-

Biosensor System

-

Electronics Protection

The reason why the medical industry prefers these is because it is safe for the human body. The FDA approved several new medical applications in 2024.

How Are They Made? The Manufacturing Process

Hot Press: Standard Method

Most transparent ceramics are produced by the hot press method. This means adding heat and pressure simultaneously.

This process requires a temperature of 1,800°C and takes 8 to 24 hours. I have visited a factory with a larger press than a car. Its press machine can manufacture 18 inch diameter parts.

Energy costs account for about 30% of total manufacturing costs. This is why these materials are much more expensive than regular glass.

Spark plasma sintering: A new method

SPS technology is transforming the way transparent ceramics are produced. This technology uses electrical pulses to heat materials at high speeds.

Benefits I have confirmed:

-

60% reduction in energy consumption

-

Reduced machining time from 30 minutes to 2 hours

-

Increased light transmission by 15-20%

-

Cost reduction at mass order by 25%

Companies that invest in SPS facilities have significantly reduced costs when manufacturing more than 1,000 pieces per year.

Where Are Transparent Ceramics Used Today?

Military and Defense Applications

In the military field, spending on advanced materials has reached record levels. In 2024, the U.S. Department of Defense granted $1.5 million in grants to each research project.

With experience with defense companies, current projects include:

-

Bullet resistant vehicle window

-

Laser Resistance System

-

Protection from electromagnetic attack

-

Chemical Resistance Insight

These contracts are usually worth hundreds of millions of dollars over several years.

Aerospace and aviation

I work with multiple airline suppliers, but they always seek lightweight and durable materials. Fuel costs are squeezing profits. Transparent ceramics can reduce weight without compromising safety.

It is difficult to obtain approval for these materials for aircraft. I’ve seen companies wait almost two years to get certification. Aviation authorities do not cut down because of the hard work of passengers.

The space industry moves faster. Satellites require materials that do not fail during a 15-year mission in harsh environments.

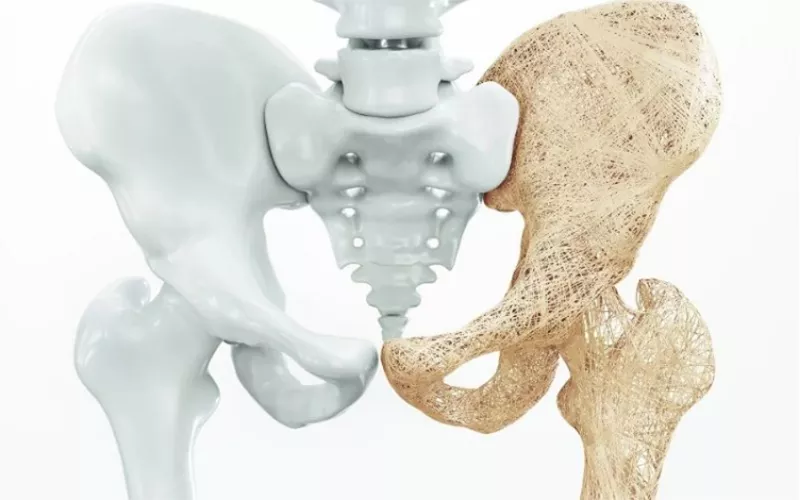

Medical and Healthcare

This year, I was thrilled to see that transparent ceramics have received FDA approval for multiple new medical applications. My dentist friend told me that these materials are game changers because the patient is indistinguishable from the real teeth.

I have been involved in consulting interesting medical projects:

-

What the doctor can check the inside without opening the equipment in the window of the surgical instrument

-

Clear medical imaging parts like crystals required for accurate scanning

-

Long-term embedded implants that do not disassemble in the human body

-

Biosensor devices to monitor patient health

Medical companies are continually expanding their use of these materials. Because patient safety is a top priority, the cost is not a major concern, but is prepared to pay a high price.

Advantages Over Glass and Other Materials

Much stronger than glass

The comparison between transparent ceramic and other materials is as follows:

-

Transparent ceramics: 300-600 MPa strength

-

Normal tempered glass: 50-100 MPa strength

-

Bulletproof Glass: 100-150 MPa Strength

-

Plastic (polycarbonate): 60-70 MPa intensity

I conducted impact tests and confirmed that transparent ceramics endured the impact of completely destroying glass samples.

Compatible with extreme temperatures

I have tested the materials in furnaces that melt most substances:

-

Transparent ceramic: continues to function at 1,600 °C

-

Tempered glass: starting to soften at 400 °C

-

Plastic: completely melted at 140 °C

This huge difference means you can put transparent ceramics next to jet engines or in furnaces where regular glass would turn into liquid.

Buying Transparent Ceramics: What You Need to Know

Who Makes Them?

I trade with suppliers all over the world. Major manufacturers include Surmet Corporation, CoorsTek, and Fraunhofer IKTS. Although they are expanding rapidly, delivery times tend to be long.

GGS Ceramic offers high-quality transparent ceramic solutions with better prices and faster delivery times. I noticed that smaller suppliers often provide better service than major companies.

Always ensure a backup supplier. When major suppliers had problems, they witnessed the company’s panic.

Current Prices and Costs

Real costs you’ll pay today:

-

ALON: $10-15 per square inch

-

Transparent spinel: $20,000-80,000 per part

-

Custom development: $100,000-350,000 for new designs

-

Energy makes up 30% of manufacturing costs

Buying 100+ pieces at once can reduce prices by 20-40%. But you need to plan 12-18 months ahead for large orders.

“We got a 35% price reduction by committing to 200 pieces per year. The planning was worth the savings.” David Chen, Procurement Manager, Optical Systems Ltd.

Lead Times and Planning

How long you’ll wait:

-

Standard products: 20-28 weeks

-

Custom parts: 6-12 months

-

Brand new designs: 12-18 months

-

Military/aerospace testing: Add 3-12 months

Supply problems affect transparent ceramics more than common materials. Smart buyers keep extra inventory for critical applications.

Future Trends: What’s Coming Next?

Research Focus Areas

Current research tries to lower costs while making better materials. Universities get over $50 million per year in government funding.

Scientists are working on:

-

3D printing methods

-

Lower temperature processing

-

Better light transmission

-

Bigger component sizes

-

New material combinations

Growing Markets

New industries starting to use transparent ceramics:

-

Consumer electronics screens

-

Car sensor systems

-

Solar energy equipment

-

Building windows

Growth predictions show 22% per year through 2031. New uses keep appearing as costs come down.

Tips for Getting the Best Results

Choosing the Right Type

Consider these factors when selecting transparent ceramics:

-

Temperature range needed

-

Chemical compatibility with your application

-

Strength requirements

-

Size limitations

-

Budget constraints

Working with Suppliers

Best practices I’ve learned:

-

Get samples before large orders

-

Verify certifications and quality systems

-

Check financial stability of suppliers

-

Have backup suppliers identified

-

Plan inventory for long lead times

“Always test samples first. We caught a quality issue that would have cost us $200,000 if we hadn’t tested.” Lisa Park, Quality Manager, Aerospace Components Inc.

Conclusion

Transparent ceramics provide you materials that have never been possible, as transparent and surprisingly strong as crystals. You can see through aluminum like glass, but it does not break unlike glass. Current applications include military transparent steel protection, aircraft windows, medical devices, and high-performance electronic devices that cannot be supported by ordinary materials.