The most promising thermal protection ceramic materials include Zirconia, Silica, Carbon-Carbon, aerogel, and ultra-high temperature ceramics. If your industry works under extreme heat, these heat-resistant materials offer unmatched performance, insulation, controlled ablation, and minimal heat insulation loss. From aerospace to energy and defense applications, these ceramic materials are the first line of defense, ensuring your safety and safeguarding your equipment. This guide explores the most magnificent, innovative thermal insulation materials and why they’re crucial for the success of your process or product.

Criteria For Evaluating Thermal Protection Materials For Your Application

-

The best thermal protection material for your high-temperature uses should balance performance, features, and cost. Thermal resistance or insulation capacity determines how well materials resist heat transfer. The thermal conductivity of materials also affects their effectiveness in resisting heat. The ratio of strength to weight is crucial, particularly for your applications in aerospace and automotive.

-

Your material’s durability in harsh environments determines how it will resist thermal shock, degradation, and erosion. The insulation material’s lifespan also matters, as it affects how many cycles it can be reused under harsh conditions.

-

Your budget is an important consideration, and a promising thermal protection material should balance costs with performance. It should also be easily fabricated, machined, and integrated into your company’s existing systems.

7 Most Promising Thermal Protection Materials in 2025

As your industry faces higher loads of heat, the need for outstanding thermal protection materials rises. The following proved and emerging ceramic materials lead the charge:

1. Ultra-High Temperature Ceramics (UHTCs)

-

Your Ultra-High Temperature Ceramics are among the most thermally resistant. These materials, including zirconium diboride, nitrides, and hafnium carbide, withstand melting points beyond 3000°C, ensuring your equipment maintains structural integrity.

-

UHTCs are ideal for your hypersonic vehicles, rocket nozzles, and thermal shielding applications. The thermal conductivity of these materials is moderate, but it’s often balanced with thermal coatings.

-

Despite their outstanding features, UHTCs cause challenges such as brittleness and are costly to manufacture. However, innovations in 2025, like nanostructuring, reinforcing carbon fibre, and additive manufacturing, have significantly helped boost strength and minimize their brittle behavior.

“After switching to UHTCs, we saw a 25% thermal margin boost on our re-entry capsule.”

—Wei L., Aerospace Materials Lead, ChinSpace Systems

2. Reinforced Carbon-Carbon (RCC)

-

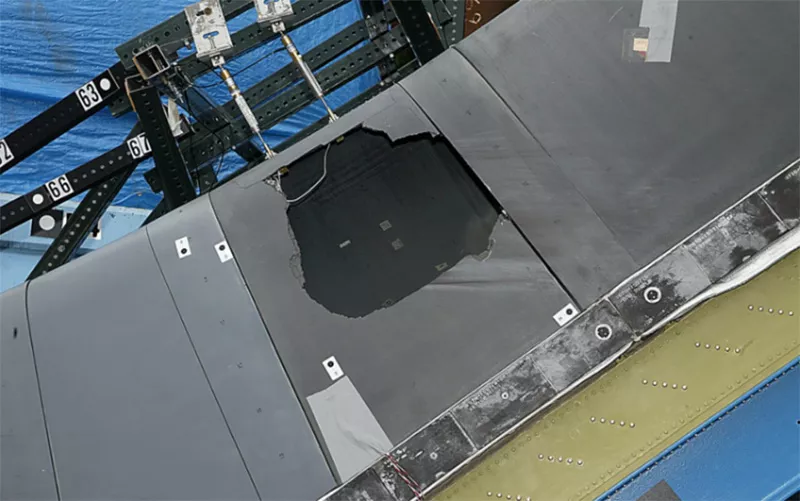

RCC was originally used on the historic NASA space shuttle. It processes carbon’s thermal resistance and structural integrity provided by the fiber composites. RCC materials withstand temperatures of up to 1650°C and offer your process very high mechanical stability.

-

RCC materials have limitations in your industrial use, such as being prone to oxidation, and may demand protective coatings. Recent improvements like silica coatings and hybrid reinforcements are helping increase their durability while minimizing erosion.

3. Ceramic Matrix Composites (CMCs)

-

CMCs offer your thermal protection system both the light strength of ceramics and higher toughness from reinforced fibres. These materials provide insulation, durability, resistance to cracks, thermal stability, and are reusable under multiple heat load cycles.

-

CMCs are used in your jet engines, heat shields, and nuclear reactors. In 2025, emerging trends like self-healing matrices have helped further improve their performance in your industry.

“Shifting to CMCs cut maintenance time by 40% in our turbines…”

—Jackson V., Plant Manager, Kenkam Aerospace

4. Zirconia-Based Ceramics (ZrO₂)

-

Zirconia materials provide thermal insulation and chemical stability, making them a great choice for high-temperature uses in jet engines. Zirconia’s low thermal conductivity makes these materials especially perfect for your thermal barrier coatings industry.

-

Zirconia also has a high melting point, chemical inertness, and phase stability, adding to its suitability in your industry. However, these materials may be expensive, but their performance value justifies the high costs.

5. Silica-Based Ceramics

-

Silica ceramics are worth paying attention to, especially if your application involves ablative or insulation coating. They absorb and dissipate excess heat as they burn slowly.

-

These materials, such as fused silica and fiber silica tiles, have low density and moderate costs. Their heat emissivity makes them especially ideal for your aerospace and shuttle industry.

6. Aerogel-Enhanced Ceramics

-

For your next generation insulation systems, incorporating aerogel ceramics is a smart move. Silica aerogel composites are lightweight and have low density and very low thermal conductivity. These materials are used in your satellite and cryogenic containers industries due to their low insulation.

-

Aerogel materials are however, are costly and fragile. Research on Aerogel-Enhanced materials continues, aiming to improve their structural integrity, reduce costs, and allow multilayer integration.

7. Functionally Graded Ceramics (FGCs)

-

FGCs help ensure your design flexibility. They vary their properties through thickness, allowing optimization of your material’s thermal shock resistance and flow of heat.

-

FGCs are ideal for your components that involve a lot of stress, including aerospace heat shields and exhaust systems. These materials allow you to customize your layers for specific temperature regions in your industry.

Summary Comparison of the Top Thermal Protection Materials

|

MATERIAL |

MAXIMUM TEMPERATURE (°C) |

THERMAL CONDUCTIVITY |

BEST FOR |

COST |

|

Ultra-high temperature ceramics |

3000+ |

Moderate |

Hypersonic flight, rocket nozzles |

High |

|

Reinforced Carbon-Carbon |

1650 |

High |

Reusable space vehicles, spacecraft, jet engines |

Medium |

|

Ceramic Matrix Composites |

1600 |

Low to moderate |

Turbines, combustion liners |

High |

|

Zirconia Ceramics |

2400 |

Very Low |

Thermal barrier coatings |

High |

|

Silica Ceraics |

1200 |

Low |

Ablative shielding |

Moderate |

|

Aerogel-Enhanced Ceramics |

650 |

Extremely Low |

Insulated panels, flexible wraps |

High |

|

Functionality Graded Ceramics |

1500 |

Custom |

Variable thermal zones |

High |

Non-Ceramic Materials Alternatives That Offer Brilliant Thermal Insulation

Advanced ceramics dominate thermal protection, but some non-ceramic materials also deliver stellar performance. They include:

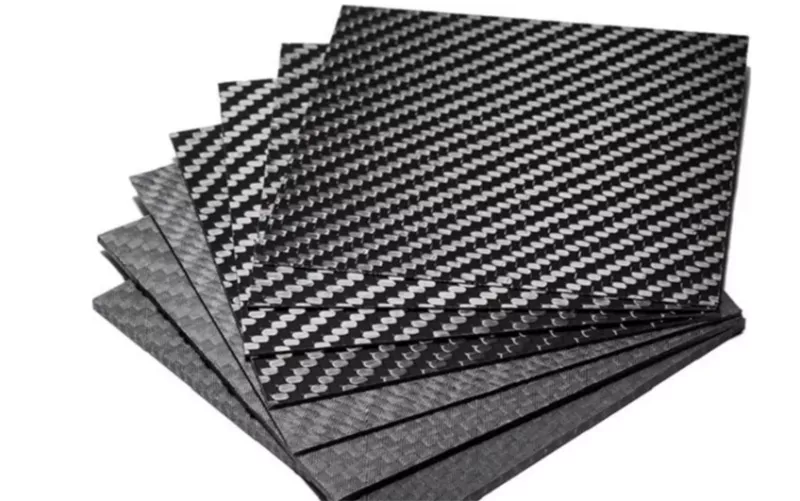

Carbon-Carbon Composites

-

Carbon-Carbon composites add carbon fibers to reinforce a carbon matrix. They offer extremely high heat resistance and are lightweight. They withstand temperatures beyond 3000°C+, but often cost more.

-

These materials outperform some ceramics in applications involving rapid thermal changes, but are, however, prone to oxidation and require protective coatings. They are ideal for your re-entry vehicles, aircraft brakes, and rocket nozzles.

Refractory Metals

-

Metals like tungsten, tantalum, molybdenum, and niobium offer very high melting points, which often go beyond 2500°C. These materials provide excellent structure strength, but are heavier than ceramics and susceptible to oxidation.

-

Refractory metals are used in your applications that involve both heat resistance and the capacity to bear mechanical loads. They do well in rocket engine components, crucibles, and nuclear systems.

Other notable non-ceramic thermal protection materials include high-temperature polymers, fiberglass, and mineral wool.

What Thermal Insulation Material Is Right For Your Process?

-

Evaluation of insulation materials should be based on thermal conductivity, manufacturability, and lifecycle cost.

-

Choose a thermal insulation material that aligns with your process’s maximum operating temperature, thermal insulation needs, weight limitations, and expected durability.

-

For a scalable, proven ceramic heat shield material, source from a reliable manufacturer and supplier like the Gorgeous Ceramic group. They offer various advanced insulation materials like UHTC coatings and RCC components tailored to your industry demands.

“We’ve been relying on thermal coatings and composites from Gorgeous for years. Their customer service is exceptional, and results have been consistent.”

—Sophia Ava, R&D Lead, Amerispace.

FAQs About the Top Ceramic Thermal Protection Material

Q: What is the most budget-friendly thermal protection material?

A: Silica-based ceramics are the most affordable and offer reliable performance for your ablative and insulation processes.

Q: What are the most promising thermal protection materials?

A: UHTCs, RCCs, CMCs, and functionally graded ceramics are among the most promising materials in 2025 because they offer versatility, high-temperature performance, and potential for innovation.

Q: What is the thermal conductivity of materials?

A: Thermal conductivity is a measure of how well your material conducts heat. Lower conductivity means better insulation.

Q: What are some good thermal insulator materials?

A: Good thermal insulator material choices include erogel‑enhanced ceramics, silica ceramics, zirconia coatings, and CMCs.

Q: What is the difference between ceramic insulation materials and thermal barriers?

A: Ceramic insulation materials minimize the transfer of heat. But thermal barriers protect certain components from being directly exposed to heat.

Final Thoughts On the Most Promising Thermal Insulation Materials

In 2025, thermal protection materials have emerged as the unsung heroes behind extreme heat innovations. For your applications, such as safeguarding satellites, boosting turbine efficiency, or insulating industrial kilns, knowing the performance and limitations of protection materials is essential. I presume that ceramics will continue to rank high in the list of most promising materials because of their heat tolerance, adaptability, and increasing demand in advanced composites.

Request your sample today from Gorgeous Ceramic and secure high thermal insulation for your application!