For many years, ceramic substrates have been an indispensable component of modern technology and industrial applications. This is primarily due to the superior properties of various substrate materials—unique mechanical strength, heat resistance, and insulation properties—making ceramic substrates the preferred choice for many industries, including electronics, automotive, and aerospace.

GORGEOUS, a leading international supplier of substrates, will now provide you with a comprehensive overview of ceramic substrates.

What are Ceramic Substrates?

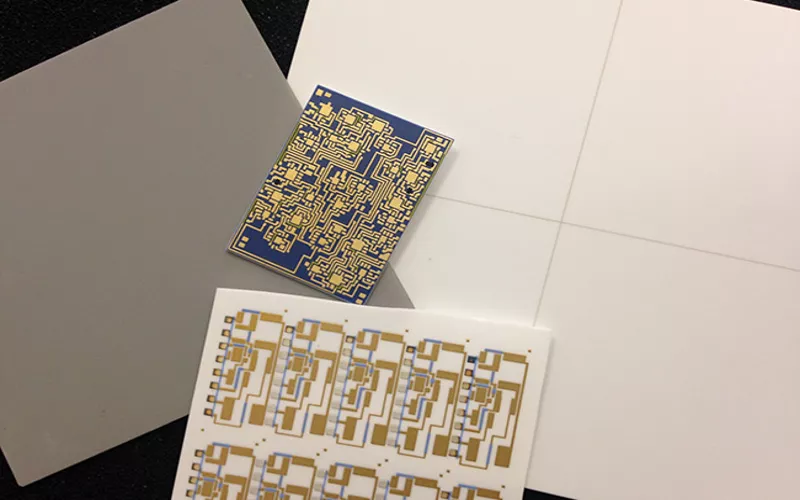

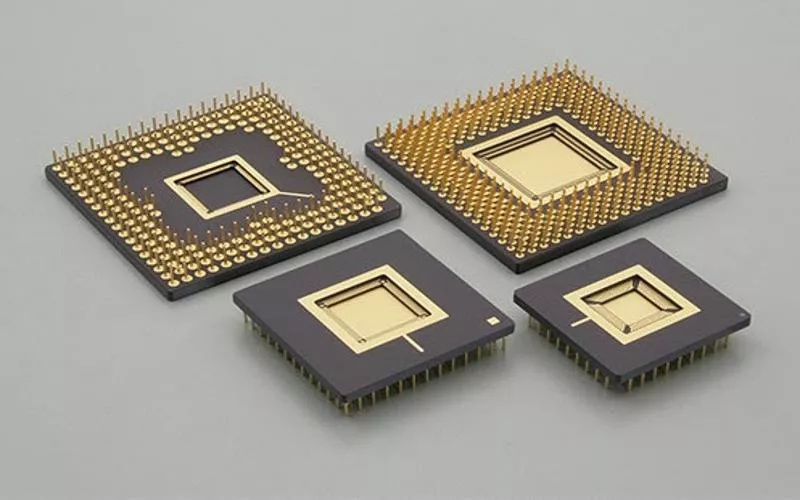

Ceramic substrates are a special type of high-grade ceramic. They typically appear in thin-layer form and are mainly made of materials such as alumina, silicon carbide, beryllium oxide, aluminum nitride, or glass ceramics. They are commonly used as substrates and carriers for various electronic and mechanical components.

What Are The Key Features Of Ceramic Substrates?

The following are some of the most notable characteristics of ceramic substrates:

Excellent Heat Resistance

One of the most impressive properties of ceramic substrates is their exceptional high-temperature resistance. Even under harsh temperature conditions, they maintain excellent performance without any failures. This makes them indispensable in high-temperature applications.

Impressive Mechanical Strength

Another notable characteristic of ceramic substrates is their strength. They are extremely robust, maintaining good performance even under pressure. In addition to their hardness, they also possess exceptional wear resistance, which is a significant reason for their long service life.

Easily Customizable

Ceramic substrates are not limited to certain shapes. Their weight and shape can be customized to suit different applications. This characteristic makes them suitable for a wide range of industries and fields.

Excellent Electric Insulators

Unlike some other ceramic semiconductor materials, ceramic substrates are excellent electrical insulators. Using ceramic substrates, you can easily prevent unwanted current from flowing through them. This property also helps protect electronic components that require isolation.

Weight

Another excellent and distinctive feature of ceramic substrates is the weight.Even though they are strong, their weight is very light.

What Are The Benefits Of Using Ceramic Substrates?

So what are the advantages of ceramic substrates? What are the advantages of ceramic substrates compared to other materials?

Ability To Withstand Harsh And Extreme Conditions

Ceramic substrates possess excellent resistance to extreme environments, meaning they can operate efficiently even at extreme temperatures. Many other substrate materials lack this characteristic. This property makes ceramic substrates the undisputed ideal material in numerous industries, including telecommunications and automotive.

Long Life Span And Durability

Unlike other substrates, ceramic substrates are durable and have a longer lifespan. They are not easily torn or worn and retain their performance even after many years. For example, ceramic substrates are used in sensors, which helps extend the sensor’s lifespan.

Customizability And Flexibility

Another important characteristic of ceramic substrates is their flexibility. Ceramic substrates are not limited to a single shape, form, or weight. Their weight and shape can be adjusted as needed to meet different application requirements. This makes ceramic substrates suitable for a wide range of applications across various industries, thus expanding their uses and influence.

Cost Effectiveness

While ceramic substrates are indeed more expensive than ceramic semiconductors and other similar materials, their durability and long service life make them more cost-effective in the long run. They are less prone to damage, thus reducing the need for replacement or modification.

Environmentally Friendly

Compared to other alternative materials, ceramic substrates are more environmentally friendly. They pose less harm to the environment; in fact, many ceramic substrates are recyclable. This makes them a better choice for industries looking to reduce environmental impact.

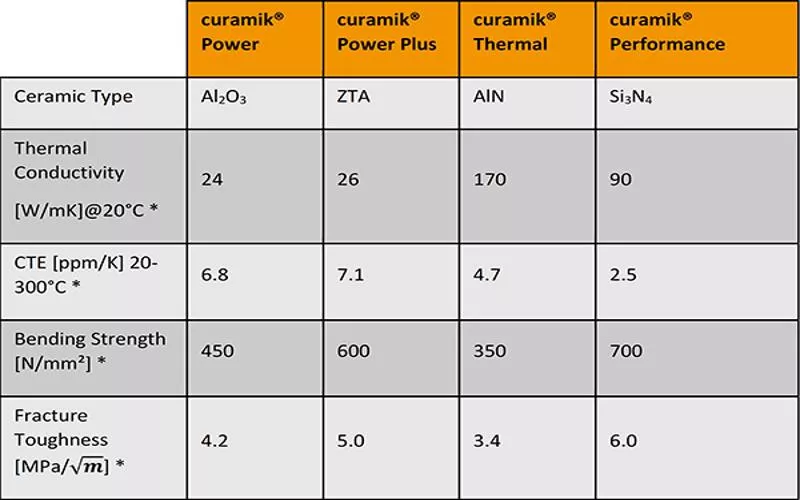

What Are The Types Of Ceramic Substrates?

There are various types of ceramic substrates, and each has different materials, for different use cases

Let’s quickly take a deep dive into what they are:

Silicon Carbide Substrate

One of the most notable characteristics of silicon carbide substrate is its exceptional strength, chemical stability, and wide bandgap. They are also commonly used in harsh environments because they maintain good performance at high temperatures. Silicon carbide substrates are widely used in industries such as automotive, gas sensors, and even aerospace.

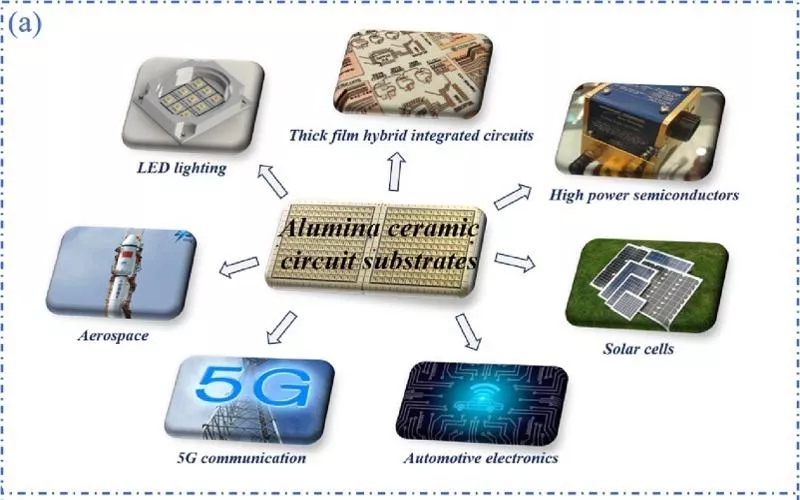

Alumina Substrate

Alumina substrates possess excellent mechanical strength and high insulation properties, and their cost is lower compared to other ceramic materials. They are the most widely used substrate material, suitable for general electronic packaging and LED applications.

Beryllium Oxide Substrate

Beryllium oxide is a commonly used material in the manufacture of ceramic substrates. Like other materials, beryllium oxide is unique in its ability to dissipate heat rapidly, but this can also lead to overheating.

Glass Ceramic Substrates

Glass-ceramic substrates are also a unique type of ceramic substrate. They are composed of a composite of glass and ceramic materials. The outstanding features of this type of substrate are its light weight and high durability. They are widely used in electronic devices and the medical industry.

Magnesium Oxide (MgO) Substrates

Magnesium oxide substrates are also an excellent ceramic substrate material. In fact, they have good heat dissipation properties, effectively preventing overheating. All these characteristics make them an important factor in high-temperature industrial applications.

What Are The Applications Of Ceramic Substrates?

Ceramic substrates have a wide range of properties and applications. Below, GORGEOUS will guide you through the various uses of ceramic substrates.

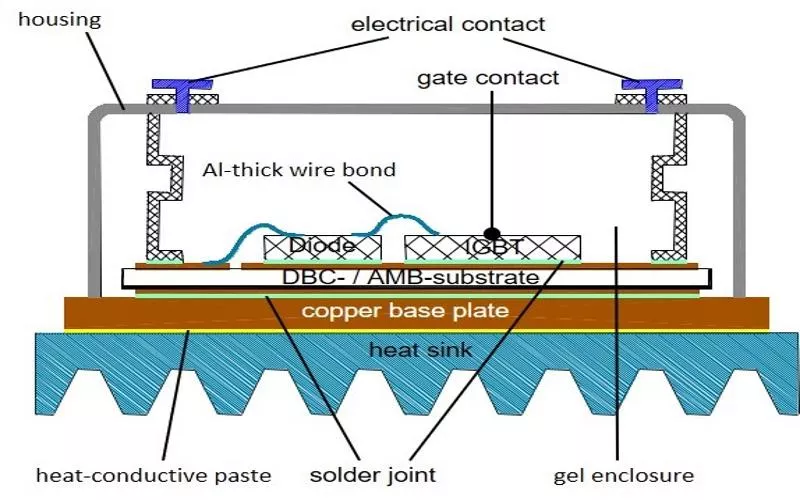

Ceramic Packaging Semiconductors In The Electronic Industry

Ceramic-encapsulated semiconductors are crucial in the electronics industry. Due to the fragility of certain electronic components, ceramic-encapsulated semiconductors effectively protect them. This makes them indispensable to industries that manufacture electronic devices.

So, what is the role of the ceramic substrate?

The ceramic substrate serves as a protective base for electronic components, and its superior properties help ensure their durability and continuous, efficient operation.

Sensors

We already know that ceramic substrates perform well under harsh temperatures. This characteristic is extremely useful in the production of gas sensors. Furthermore, in ceramic-encapsulated semiconductors, they also improve sensor efficiency, thus helping gas sensors to detect gases efficiently and accurately.

Therefore, whether detecting toxic gases or gases of specific concentrations, they help sensors operate efficiently.

Medical Industry

You might have noticed the emphasis laid on the application of ceramic substrates in the medical line.

This is what is meant by that:

Biocompatibility and durability are core components of many medical devices and guess what, ceramic substrates champion its effectiveness.

Peacemaker is one such medical device that is used on patients with heart ailments.

In applications like this, ceramic packaging semiconductors also help to safely house delicate electronic components.

Ceramic substrates is best for medical industry as they don’t trigger any unwarranted reactions when in contact with the human body.

The Automotive And Aerospace Industry

Ceramic substrates are equally crucial in the aerospace and automotive industries. They help ensure that ceramic-packaged semiconductors function well even under harsh temperatures. Some of the types we mentioned earlier (such as alumina) are used in numerous fields, including ignition control and engine control.

Electronic

The electronics industry requires highly efficient semiconductors to handle high currents. Ceramic substrates, with their excellent thermal conductivity, aid in heat dissipation and ensure the system operates as expected.

Other advanced ceramic materials, such as heat-resistant silicon carbide, are also favored ceramic substrate materials in the electronics industry. Electric vehicles and even solar power generation systems are typical applications of ceramic substrates.

In Conclusion

Ceramic substrates are an indispensable component of modern electronic and industrial systems.

If you are looking for a reliable ceramic substrate supplier, GORGEOUS is the ideal choice.

We offer high-quality alumina, silicon carbide, and other advanced ceramic substrates, and can tailor solutions to your application needs.