Throughout history, we have seen the Romans use steel as body armor and helmets to protect themselves in battle. While we have come a long way from those iron-clad days, the concept of self-defense and body armor has evolved dramatically. Steel is a rigid material that limits your mobility, and when a bullet strikes a steel plate, there is a chance that the fragments will hit the person wearing the armor. However, modern advancements have introduced new materials that provide a lighter, stronger and more efficient alternative to steel. Meet boron carbide ceramics, a game-changing material in modern body armor.

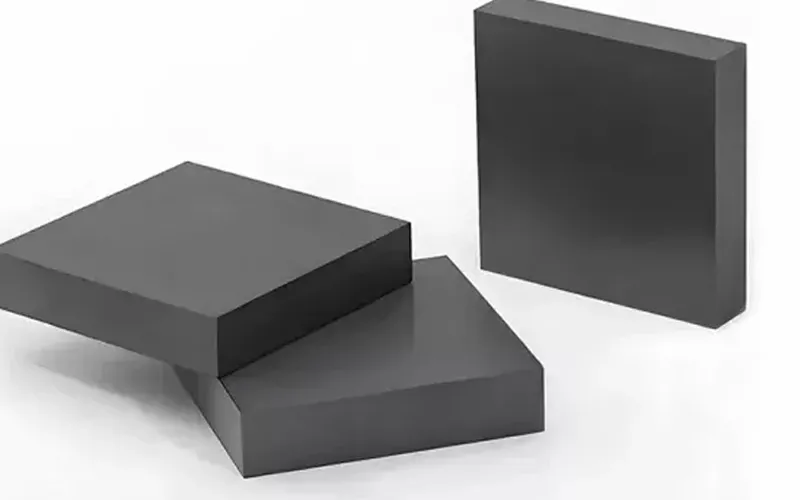

Ceramic body armor plates have unmatched hardness and low density, which makes them one of the most advanced options for stopping a high-speed projectile. The best part? You get this superior protection without the additional baggage that comes with traditional armor. So, how exactly does boron carbide armor work, and why is it a material of choice for current military operations and law enforcement? Let’s explore the growing applications and properties of boron carbide ceramics.

Why Use Ceramics in Body Armor?

The advent of ceramics has been a huge breakthrough in ballistic protection, providing protection that metal armor can’t match. So why are ceramic materials like boron carbide so effective?

How Ceramic Materials Differ from Traditional Metal Armors

Traditional armor such as steel is extremely tough and can withstand huge impacts. Therefore, it is valued by people and used in various high-protection occasions. Steel is durable, resilient, and has a high capacity to absorb the force of a bullet, but there is a caveat though — it’s heavy and clunky. Steel’s rigidity transfers most of the impact to the wearer which creates a backface deformation or BFD. The sheer force of the hit can cause blunt trauma, even if the bullet doesn’t penetrate.

Ceramics, on the other hand, work very differently. Ceramic materials like boron carbide are stronger than steel, but instead of absorbing the force of the impact, they disperse it by fracturing the projectile on contact. This shattering effect breaks the bullet apart and prevents it from penetrating through the armor. This quality makes ceramics especially useful for stopping high-velocity, armor-piercing ammunition.

However, after receiving a strong impact, the ceramic plate is very easy to crack or break, which is an inevitable defect of ceramic materials.

What Is Boron Carbide?

Boron carbide is also referred to as a ‘super hard’ ceramic, which sums up its qualities perfectly. Boron carbide is one of the hardest substances on Earth, ranking just behind diamond and cubic boron nitride. This makes boron carbide an ideal ceramic for industries where durability and protection are critical. First discovered back in the 19th century, B4C(boron carbide) is made by combining boron and carbon atoms in a tightly bonded crystal structure.

Unique Properties of Boron Carbide

Low Density:

One of the trademarks of boron carbide is its incredible hardness, with a Mohs hardness rating of around 9.5. The strength of this ceramic can only be surpassed by diamonds and a few other ultra-hard compounds. This hardness also makes it extremely effective at resisting abrasion, impact and penetration.

High Hardness:

You might expect that since a ceramic is extraordinarily hard, it should be heavy, too. The case is the opposite for boron carbide because it has a density much lower than metals like steel and even aluminum. This low density gives boron carbide a significant upper hand in applications like body armor, where mobility and stealth are essential. For soldiers or law enforcement personnel, wearing lighter armor means less fatigue and greater agility in the field.

High Thermal Conductivity:

Another standout feature of boron carbide is its ability to conduct heat efficiently. In body armor applications, this property helps dissipate the heat generated from the impact of high-velocity projectiles. Beyond body armor, this high thermal conductivity makes boron carbide valuable in industries like nuclear energy and high-temperature manufacturing, where heat resistance and stability are crucial.

Applications of Boron Carbide

Boron carbide ceramic checks all the boxes that make it ideal for body armor. Here are some military applications where boron carbide is used:

Body Armor: Boron carbide is widely used in the production of advanced ceramic body armor plates. Its lightweight nature, coupled with its ability to stop armor-piercing rounds, makes it a top choice for military and law enforcement personnel.

Helicopter and vehicle armor: Boron carbide ceramics are not only used in personal protection, but can also be used to strengthen the armor protection of military vehicles, aircraft and helicopters.

Boron carbide ballistic shields are most commonly used by SWAT teams and military units, providing superior protection in high-risk situations. This advanced material ensures optimal strength and lightweight mobility, making it an ideal choice for dynamic combat operations.

How Boron Carbide Ceramics Work in Ballistic Protection

Here is the science of how boron carbide ceramics protects people from ballistic threats like bullets and shrapnel:

The Science Behind Energy Absorption

The main concept behind ballistic protection is to find a material that can manage and absorb the energy from a projectile, like a bullet. When a round traveling at high velocity hits a ceramic armor plate made with boron carbide, the material goes through a fascinating energy absorption process. Here are the three stages of that process:

Initial Impact:

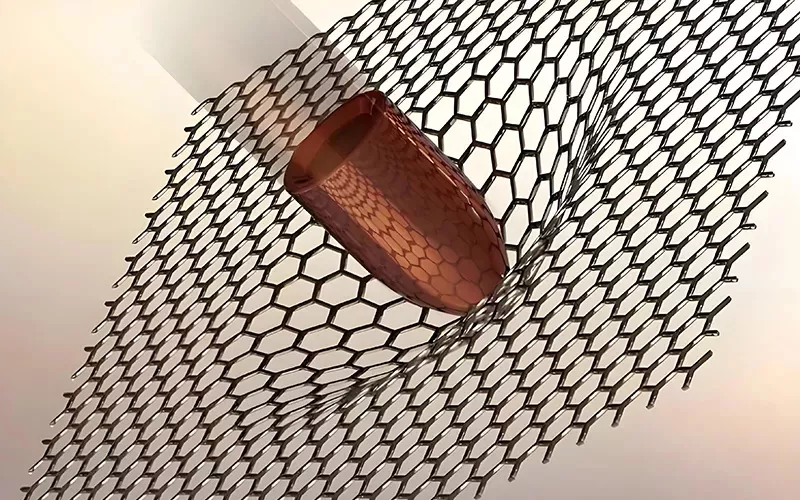

When the projectile first hits the boron carbide armor, the ceramic’s diamond-like hardness causes the project to deform or fragment upon impact. This happens because the bullet cannot pierce the ceramic surface easily due to boron carbide’s superior hardness.

Erosion:

When the bullet continues to exert force on the ceramic plate, the boron carbide starts to break or erode. This is done in a controlled manner, and the process of localized shattering allows the material to dissipate the energy from the impact. So, instead of letting the projectile pass through the armor, boron carbide sacrifices itself by breaking into tiny fragments and spreading the impact force to a larger area.

Deformation:

In the end, there is a backing material (often a composite or fiber layer behind the ceramic plate) that absorbs any remaining energy. This layer helps catch any remaining fragments from the projectile and the ceramic, preventing them from penetrating further. Even if the ceramic plate is damaged or cracked after absorbing the initial hit, the wearer is protected from the sheer force of the bullet.

Wrapping Up

Boron carbide has changed the way we think about body armor and protection. Its lightweight yet ultra-strong properties make it an invaluable asset for personal protection, giving soldiers and law enforcement the confidence and freedom to perform their duties more effectively.