Do you want to know what cordierite ceramics are and how they’re transforming product manufacturing? Whether you’re a manufacturer or simply interested in knowing about cordierite ceramics, this blog post is for you. Here, you’ll quickly know everything about cordierite ceramics, from their properties, to manufacturing processes, types, applications and limitations. So, let’s get into learning about them.

What are cordierite ceramics?

Cordierite ceramics are refractory structural ceramic materials comprising silicate, magnesium, aluminum, and iron. With a chemical formula of (2MgO-2Al2O3-5SiO2), cordierites have exceptional thermal shock resistance and thermal expansion resistance. They can withstand as high as 1000℃ working temperature with their 1350 ℃ sintering temperature. This is the reason these specialized ceramics are suitable for your high-temperature applications. Their wide-range use includes kiln furniture, catalytic converters, heat exchangers, and electronic components. Since these powder-like materials were first discovered by a French geologist, Louis Cordier, they’ve been named after him.

Key properties of cordierite ceramics

-

Thermal shock resistance: Cordierite ceramics don’t mind sudden temperature changes, which translates to their higher thermal shock resistance.

-

Low expansion on high temperatures: Cordierite ceramics don’t expand easily at high temperatures. This means they retain their volume and size under challenging conditions.

-

Low electric insulation: Cordierite ceramics let no electric current pass through them. Their insulation properties make them an excellent choice for your electric components, like fuses.

- Higher chemical resistance: Cordierite ceramics also show incredible tolerance against weather and chemicals — they don’t rust or decay easily.

Overall, cordierite ceramics’ uniqueness makes them an ideal material for challenging use.

How are cordierite ceramics manufactured?

Since the limited availability of cordierite ceramics in nature can’t fulfill manufacturing industry needs, you may need to produce them synthetically and then structure them. This process is pretty complex and needs high-end equipment. However, below is a step-by-step overview of cordierite ceramics’ manufacturing process.

Step-1 Selection of high-quality raw material

Cordierite ceramics’ production starts with a careful selection of high-quality raw materials. For this purpose, materials like talc, kaolin, and alumina provide essential compounds of magnesium oxide, aluminum oxide, and silica. These materials need weighing and mixing, following the stoichiometric ratio that cordierite materials need.

After mixing in the right quantities, these materials go in ball mills for uniform grinding so that every particle is of an even size. This uniformity of particles helps the material receive even heat at the later stage for a consistent quality.

Step-2 Preparation

In the first step, primary cordierite material is ready, which is in a powder form. Next comes the shaping part. The obtained cordierite ceramic powder has less binding ability. That’s why you need to add binding agents for compressing or molding in the required shapes.

Step-3 Shaping

After mixing additives, these ceramics can be shaped using different techniques like extrusion, dry pressing, or slip casting. However, you need to select the shaping technique depending on the complexity of the shape. Once shaped, these ceramics need drying to ensure no moisture is left behind.

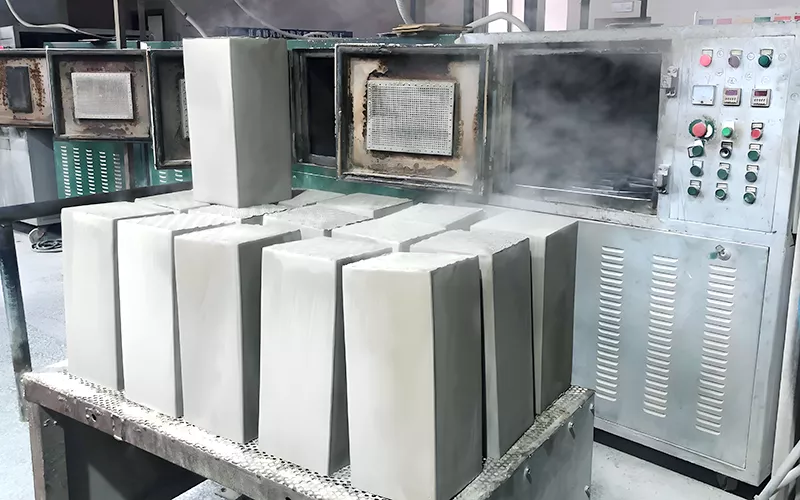

Step-4 Sintering

Just like pottery needs heating for strength, prepared shapes of cordierite ceramics must undergo an intense heating process, what’s known as sintering. So, you need to heat these shapes in kilns at 1200℃ to 1450℃ depending on the mixture formula. This below-melting point heat allows the particles to fuse together and maintain their shape in the future.

Step-5 Cooling

After sintering, these cordierite ceramic shapes need cooling. However, the cooling process should be slow to avoid any thermal shock at this delicate stage of manufacturing.

Step-6 Secondary processing

Not necessary, but depending on their intended use, these ceramic shapes may need grinding, cutting, or coating.

Step-7 Quality checks

After getting the finished product, a strict quality check is essential. These checks ensure consistent temperature shock resistance, thermal expansion resistance, strength, density, porosity and electric insulation. Result is an ultimate value—consistent performance.

Step-8 Packaging and supplying

Finally, the cordierite ceramics are ready to go to the users — whether from industries or common people. You can pack and label them accordingly.

What are the different types of cordierite ceramics and their applications?

Look, all cordierite ceramics have almost similar resistance to temperature changes and related expansion. However, you can control their porosity and density, considering their usage. For instance, ceramics used for making filters have higher porosity and less density. In contrast, those used in electric applications may have higher density and less porosity.

So, depending on their engineered properties, cordierite ceramics can be porous or dense. At the same time, some additives may also enhance their insulation or thermal shock resistance. However, their recommended formula is almost similar: 13.8% of MgO, 34.8% of Al2O3 and 51.4% of SiO2, making 2MgO, 2Al2O3, 5SiO2 chemically.

What are the applications of cordierite ceramics?

Cordierit ceramics’ unique qualities make them suitable for a wide range of industrial or everyday use. Some of these are as follows:

Kilns’s furniture

Structural cordierite ceramics are part of a high-temperature environment like kilns or furnaces. They’re used as the furniture there, like shelves, push plates, and columns.

Electric insulations

Thanks to their dielectric properties, cordierite ceramics are heavily relied on for making insulated parts like thermostats, fuse and other lighting.

Filtration systems

Formed as honeycomb structures, lightweight, highly porous cordierite ceramics are part of filtration systems and catalyst carriers.

Industrial filtration of molten metals

Porous cordierite ceramics, with their higher porosity and thermal resistance, help with the filtration of molten metals during chemical processing. Such an incredible porosity makes them suitable for high-end usage.

Lightweight thermal insulation

With the highest porosity and lowest density, foam like cordierite ceramics help with lightweight thermal insulation industrial processes. Such use of cordierite foam ceramics is a wide range.

Catalytic converter substrates

Cordierite ceramics make an excellent choice as catalytic converter substrates. With their low thermal expansion and high porosity, they help with the filtration of exhaustive gasses in automobiles.

Cookware aka. Flameware

Last but not least, the most common use of cordierite ceramics is in preparing cookware. You can find them everywhere, from baking to grilling–thanks to their matchless temperature tolerance and thermal shock resistance. Pizza stones, baking stones, ceramic briquettes, casserole dishes are just a few examples.

What are some limitations of cordierite ceramics?

Just like any other material, cordierite ceramics have some limitations. You can consider them before opting for cordierites. Some of these are:

-

Cordierite ceramics lack strength — any forced interaction like loading, hitting, or fall can break them. So, you can’t load them heavily or handle them roughly.

-

They can still break as a result of sudden temperature changes, especially if thinly made. Pizza stones and baking stones are common examples of their vulnerability.

-

Since cordierite ceramics have a limited melting point of about 1460 degrees centigrade, you can’t push their limits. That’s why they poorly withstand secondary phase formation.

-

Last, cordierite ceramics require complex manufacturing. So, they cost heavily.

Conclusion

Despite their limited temperature standing range, lack of strength, and higher manufacturing costs, cordierite ceramics are still great for various applications. They’ve great advantages over many other materials within their thermal shock and thermal expansion ranges, besides their insulation. You can consider using them if they suit your needs and budget.