Not many people are left with the knowledge of zircon, a mineral from which zirconium is extracted. Yet, the resource it gives industries such as nuclear plants, mechanical engineering, chemical industry, dentistry, and medicine at large is indispensable. Zirconium comes with perks like thermal stability, high density, hardness (harder than aluminium metals), and high pressure resistance. A few more upsides of zirconium are high oxygen ion conductivity and a high melting point.

Yet zirconium undergoes undesired phase changes, especially during high-temperature conditions. Hence magnesium oxide is used as a stabilizer. This opens up a pool of advantages that about every industry sector can benefit from.

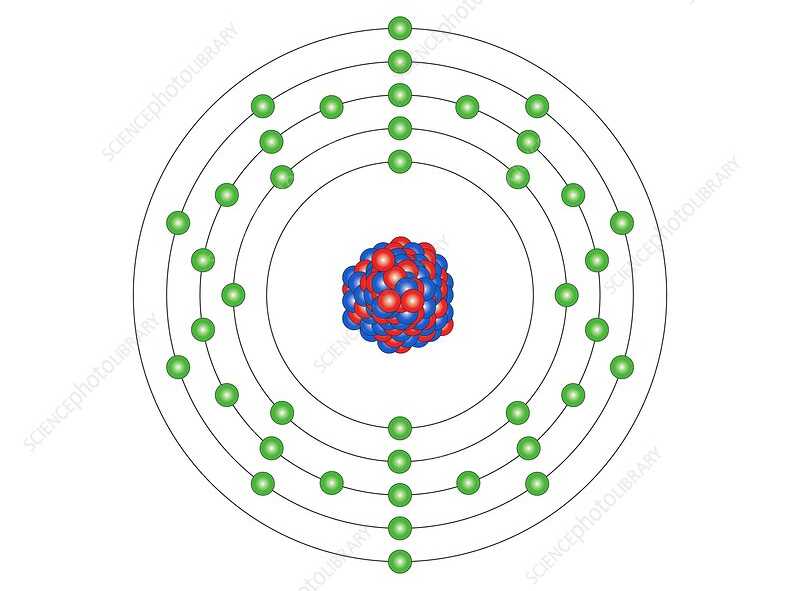

What is Zirconium?

At a glance, zirconium is a silver-gray metal that’s highly ductile and has incredible heat resistance. The metal has a heat endurance and only melts at temperatures exceeding 1855 degrees Celcius. Being a valuable industry resource, you might wonder how rare zirconium must be!

Well, it’s extracted from zircon, a mineral that’s widespread beneath the sand of many coastal waters. Note that the mineral deposits are widespread across the earth’s surface rather than concentrated. The mineral is quite popular in China, Australia, Ukraine, Indonesia, and South Africa.

Having been discovered in 1795 by Martin Klaproth, a German chemist, the mineral didn’t go up the ranks in industry use. However, the charts started going up when the first pure zirconium (without other elements or stabilizers) was produced in 1925. The metal’s use spiked in the 1940s when many nuclear plants discovered its thermal and chemical resistance.

What is Zirconium Used For?

About 90% of zirconium is used in nuclear power plants as cladding in nuclear reactors. Its high melting and boiling points make it withstand extreme temperature conditions. Besides, it is highly non-reactive to chemicals, as it does not absorb neutrons during nuclear fission reactions. This makes it an excellent cladding for the fuel rods and up to the task of a coat around uranium pellets.

Despite its huge use in nuclear power, zirconium’s relevance cuts across many industries including artificial gemstones, mechanical engineering, filaments, dentistry, and the chemical industry. Zirconium’s remarkable resistance to chemical reactions makes it a major asset in the latter industry.

The metal’s versatility makes it a prey to chemical manipulations to get the most out of it. For instance, zirconium is combined with oxygen to get zirconium oxide or zirconia. The latter offers a deluge of industry uses worth investing in.

Zirconia at a Sleek Glance

Zirconia occurs naturally but can also be produced synthetically by derivation from zircon or zirconium silicate (ZrSiO4). Being one of the most important oxides derived from zircon, zirconia applies to many industrial needs like dentistry.

Zirconia in Dentistry

Through the years, dentists have tried to come up with ways to elevate smiles and oral health. And while some teeth, broken and worn out, might not be remineralized, patients resort to metal or porcelain fillings. With the breakthrough of zirconia dental crowns, folks are turning to crowns that can last their smile for more than 2 decades.

If you’ve been struggling with weak and misshapen teeth, zirconia crowns could take you through years of chewing hard food while enduring all the pressure exerted. While zirconia ceramic crowns are a new go-to, many people prefer porcelain for front teeth. The main concern here is zirconia crowns for front teeth don’t match the other teeth.

A 2016 study of the safety of zirconia crowns to the body established its biocompatibility. Meaning, the crowns don’t trigger the body to produce responses or reactions like inflammations. Its biocompatibility combined with high mechanical strength makes zirconium dioxide useful in bone regeneration.

Magnesia Stabilized Zirconia (MgO-ZrO2)

While pure zirconium dioxide provides a breakthrough in many industries, it fails to remain stable during elevated temperatures, after sintering. Since it goes through a tetragonal monoclinic phase change, it loses stability and the volume changes as it cools down. Hence, it is stabilized with metal oxides like magnesium oxide that give it a tetragonal phase during elevated temperatures. Thus, magnesia-stabilized zirconia (MSZ) has superior mechanical abilities.

MSZ’s resilience against phase transformation makes it corrosion-resistant. Being biocompatible, MSZ is safe for use in orthopedics and dentistry.

Magnesia-stabilized zirconia’s resilience against phase transformation helps it retain its mechanical properties and high thermal resistance, as needed in ceramics. Other materials are prone to thermal expansion, wear, chemical corrosion, and phase transformation. MSZ hence becomes an efficient coating for exhaust systems, furnace linings, and gas turbines.

How is Magnesia Stabilized Zirconia Used in Ceramics?

-

Medicine: MSZ is a solid biocompatible material that can be used to strengthen weak and worn-out teeth, prosthetics, and worn-out joints.

-

Mechanical engineering: MSZ’s high resistance to wear and tear makes it ideal for the manufacture of cutting tools and non-resistant parts.

-

Thermal resistant materials: Such materials may be employed in aerospace and nuclear power industries where there’s creation of high energy and temperature. They are useful in the making of furnace linings and turbine blades too.

-

Electricity: Due to poor electrical conductivity, thermal stability, and incredible dielectric strength, MSZ ceramics are used to manufacture insulators.

Properties of Magnesia Stabilized Zirconia

Mechanical Properties

-

Color: Yellow

-

Density: 5.7g/cm3

-

Compressive strength: 2500MPa

-

Elastic modulus: 250GPa

-

Weber’s coefficient: 12M

-

Vickers hardness: 1100 HV0.5

Electrical Properties

-

Dielectric constant: 28εr

-

Dielectric strength: 13 x 105 V/m

Thermal Properties

-

Thermal conductivity: 3 W/m·K

-

Max. operating temperature: 2100℃

Conclusion

Magnesia-stabilized zirconia is a valuable input into the ceramic field that is most probably here to stay. For its corrosion and temperature resistance, the material might remain sought-after for years, especially when in its stabilized form. For its widespread availability on the earth’s surface, companies aren’t having a hard time extracting it and in the right amount.