Are you curious about “cordierite”? Many people associate it with mineral gemstones. In fact, it is not only a crystal, but also a material widely used in modern industry and daily life.

With its excellent thermal shock resistance and low thermal expansion, cordierite ceramic plays a very important role in catalyst carriers, kiln furniture, and even kitchen pizza stones.

What is cordierite? What are its properties? How to choose the cordierite products that suit you? Please hold these questions in mind. After reading this article, I believe it can solve your various doubts and provide professional guidance for your purchase and selection.

Quick Navigation

- What is Cordierite?

- Characteristics and Advantages of Cordierite Ceramics

- Application Fields of Cordierite

- How to Choose Cordierite Products?

What is Cordierite?

Cordierite is a silicate mineral with a chemical formula of 2MgO·2Al2O3·5SiO2, mainly composed of magnesium, aluminum and silicon. It is named after the French mineral geologist Louis Cordier.

Natural cordierite exists in high-temperature metamorphic rocks, granites and rhyolites, and can also be synthesized artificially. To understand what it is, you can’t just focus on its definition. In practical applications, you can feel its value more intuitively:

What is the difference between iolite and cordierite?

While “cordierite” and “iolite” refer to the same mineral, they are used in different contexts. “Iolite” is the gem-quality variant of cordierite and is commonly used in jewelry, while “cordierite” typically refers to the material used in ceramics, refractories, and industrial applications.

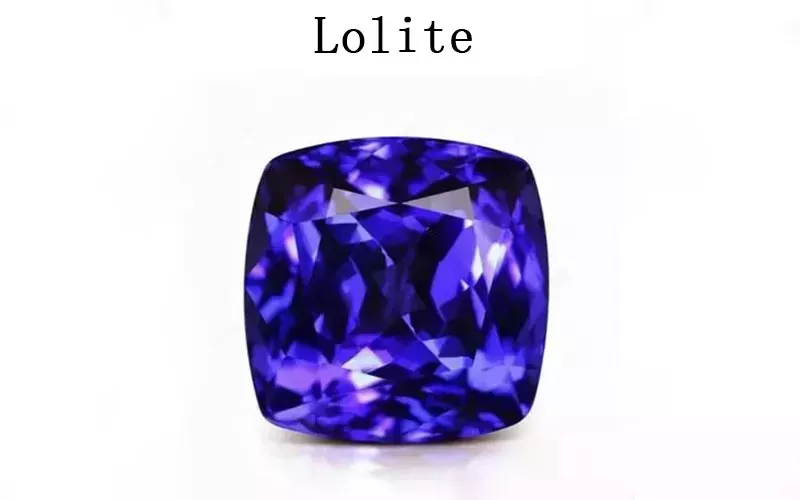

Iolite in mineral gemstones: It is loved by jewelry lovers for its unique and beautiful ballistic blue-purple color. The picture below is a beautiful iolite gemstone.

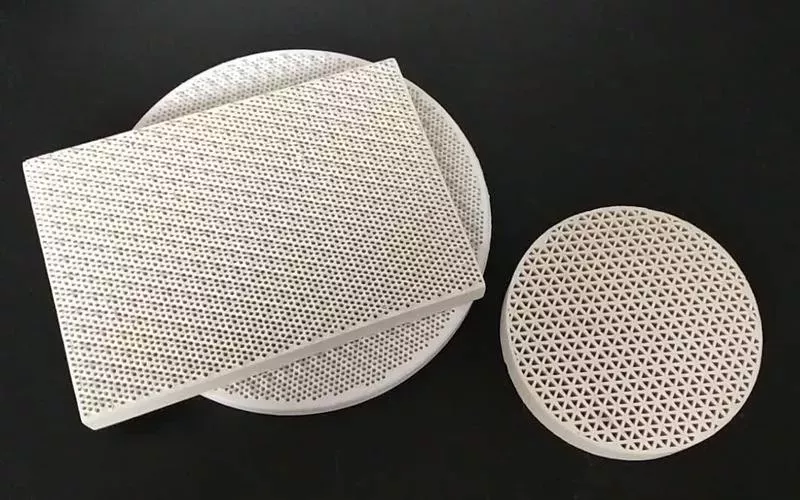

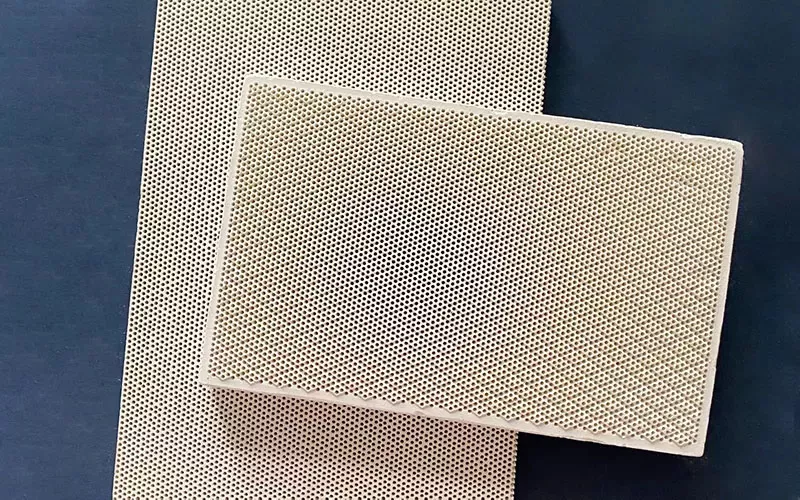

Cordierite ceramic: cordierite ceramic is a synthetic technical ceramic. It is famous for its excellent thermal shock resistance and low thermal expansion coefficient. It is a “good partner” in many industries. The picture below is of cordierite ceramics.

Characteristics and Advantages of Cordierite Ceramics

Cordierite ceramics are a very common ceramics, which are widely used in daily life. Here we will introduce the characteristics of this ceramics.

Thermal shock performance:

Cordierite ceramics have an extremely low coefficient of thermal expansion and are not prone to cracking when heated and cooled rapidly under high temperature conditions.

High Hardness:

With a Mohs hardness of about 7, cordierite ceramic is a very hard material, which makes it very scratch-resistant.

High temperature resistance:

Cordierite ceramics have strong high temperature resistance and can work at temperatures up to 1200°C, which makes it very useful in high temperature operations. The most direct manifestation of this superior performance is that it can be used in automotive catalytic converters and pizza stones for baking (the best pizza stone material). In addition, this ceramic can also be used for furnace bricks and high-temperature pads in industrial kilns, which shows that it has a wide range of uses.

Lightweight:Compared with other refractory materials, cordierite has lower density and lighter weight. This feature can reduce energy consumption and improve efficiency. Due to its strong high temperature resistance, it is often used in automobile exhaust treatment systems to help optimize fuel efficiency.

Corrosion resistance: Like most ceramic materials, cordierite is resistant to acid and alkali corrosion, which ensures its long-term use in harsh environments.

Environmentally friendly and non-toxic:

Is cordierite toxic? You can be absolutely assured that cordierite is non-toxic and environmentally friendly, and it can be used in the food industry, such as baking stones and pizza stones.

Application Fields of Cordierite

Cordierite has a variety of excellent properties and shows high practical value in many fields. From industrial manufacturing to household applications, I will give you examples one by one.

Industrial field

Automobile emission control system: Cordierite has excellent heat resistance and low thermal expansion characteristics, and it is lighter than most ceramic materials. Therefore, it has become an ideal carrier material for automobile catalytic converters (such as honeycomb ceramic filters), which plays a very critical role in reducing emissions and protecting the environment. If you are an environmentalist, this will definitely be something you like.

High temperature industrial equipment: Cordierite bricks can be used as kiln support plates and kiln furniture, which plays an important role in the ceramic sintering and glass manufacturing industries. They are excellent thermal insulation and heat-resistant materials.

Electronics and electrical: Cordierite has high insulation properties, which is an ideal substrate material for some electronic devices.

Daily Life

Baking and cooking tools

If you are a cooking enthusiast, then the relevant cordierite products must be your right-hand man. Cordierite is an ideal material for making pizza stones. Compared with traditional porcelain, it heats faster and more evenly, improving baking results, and pizza stones made of cordierite are non-toxic and harmless, giving you peace of mind.

Jewelry:

Iolite crystals, also known as the iolite gemstone, have a stunning bluish-purple hue. Many people appreciate its beauty and have fashioned it into popular accessories such as iolite bracelets and rings.

How to Choose Cordierite Products?

If you’re excited about the uses of cordierite but unsure where these products are actually applied, the following overview will make everything clear!

Pizza Stone: If you love cooking, you will pay special attention to the safety of food and cookware, and you are eager to find a non-toxic pizza stone. Then the cordierite pizza stone will be very suitable for you. The excellent and uniform heat transfer rate can shorten your cooking time!

Cordierite vs other materials: It is more thermally stable than other ceramic materials and stainless steel in food heating applications. It is suitable for some applications that require high thermal conductivity. They each have their advantages, and you should choose according to your needs!

Cordierite ceramics: Cordierite ceramics serve various industrial applications, typically categorized into products for high-temperature use and those with excellent thermal shock resistance.

High Temperature Applications - Cordierite is used in high temperature applications. Common products include ceramic tiles, pallets, etc. These products are resistant to high temperatures and are suitable for applications in high temperature harsh environments such as kilns.

Thermal shock applications - In environments where the temperature often rises or drops rapidly, such as automobile exhaust systems, cordierite is very suitable. For example, honeycomb ceramics used as the core of catalytic converters. This specially customized ceramic can easily convert harmful gases in automobile exhaust and reduce pollutant emissions!

Comparison with other materials: Compared with other materials, the cost of cordierite for industrial applications is usually higher. If you have a limited budget, you can consider some ceramic materials with higher cost performance. Among some alternative materials, aluminum silicate and alumina ceramics are very competitive. How to choose these materials requires you to make a reasonable choice based on the specific project.

Summarize

With its excellent low thermal expansion and high temperature thermal shock resistance, cordierite has gradually become an indispensable material in industry and life. By understanding it, we can not only better meet the current diversified needs, but also promote innovation and lay the foundation for improving environmental protection standards!