AlN Ceramic

Aluminum Nitride Ceramic

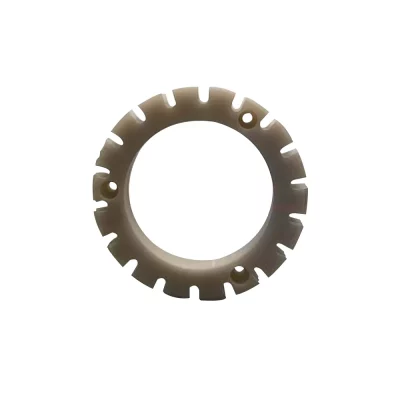

Aluminum nitride ceramics are composed of aluminum nitride (AlN) and are ceramics with aluminum nitride (AlN) as the main crystal phase. Molded from aluminum nitride and then sintered at high temperatures. Mainly used for aluminum nitride substrates, crucibles and aluminum nitride wafers.

High quality and good price!

AlN /Aluminum-nitride

Gorgeous Advantage

What is Aluminum Nitride Ceramic

Aluminum nitride ceramics are made of aluminum nitride (AlN) sintered at high temperature. The molecular formula of aluminum nitride is AlN, the molecular weight is 40.99, the common melting point is mp 2400°C (dec), and the common density is d 0.00326 g/cm3. Its common Its structure is cubic β-AlN and hexagonal α-AlN. It is an advanced ceramic material with excellent performance. The thermal conductivity of aluminum nitride is usually between 100-320W/(m·K), which is related to the purity and preparation process. The better the preparation, the higher the purity, and the higher the thermal conductivity. It is also affected by the temperature environment. Aluminum nitride (AlN) ceramics have good high temperature resistance and mechanical strength, and can remain stable under high temperature, high pressure, and harsh environments. Mainly used to manufacture ceramic heat sinks, aluminum nitride substrates, packaging materials, sensors, high-frequency electronic devices, aluminum nitride wafers and aluminum nitride crucibles, etc.

Aluminum Nitride Ceramic Product List

AlN Ceramic Product List

Aluminum Nitride

AlN Ceramic Main features

High Thermal Conductivity

Aluminum nitride ceramics have high thermal conductivity. Under ideal conditions, it can reach up to 300W/(m·K). It is one of the best choices for semiconductor heat dissipation components.

High temperature acid and alkali resistance

Aluminum nitride ceramics have extremely strong resistance to high temperatures and acid and alkali, with a temperature resistance of up to 2400 °C,especially suitable for laboratory crucibles, etc.

Good Mechanical Properties

Aluminum nitride ceramic three-dimensional structural parts have good mechanical properties and can be used stably in harsh environments, such as in various battery components.

Product Feature Box

High Hardness

Mohs hardness reaches 9-9.5, strong wear resistance.

Excellent Thermal Conductivity

Excellent thermal conductivity, ideal high temperature heat dissipation material.

Good Chemical Stability

Acid, alkali and salt corrosion resistant, suitable for chemical industry.

High Temperature Stability

Stable at high temperatures, suitable for high temperature heater and furnace applications.

Thermal Shock Resistance of Aluminum Nitride Ceramics

Aluminum nitride ceramics have a special structure and excellent thermal shock resistance. AlN can be generated at 800°C - AION’s thermal shock resistance is better than oxide refractory materials such as ALO3 and MgO, making AlN-based refractory materials.

The corrosion resistance is better than non-oxide refractory materials such as SiC, Si, and N. Thermal shock resistance refers to the ability of a material to resist thermal shock and thermal cycle effects under high temperature conditions.

GORGEOUS has a professional R&D team, years of technology accumulation and continuous investment, which is the cornerstone of helping customers solve heat conduction and heat dissipation problems in the best way. At the same time, we also provide customers with services such as processing of supplied materials, drawings and engineering design.

AlN/Aluminum nitride mechanical properties

| Name | AlN/Aluminum nitride | |||

| Density | g/cm3 | 3.31 | ||

| Modulus of Elasticity | GPa | 310 | ||

| Fracture toughness | Mpa x m^1/2 | 3.5 | ||

| Poisons Ratio | – | 0.25 | ||

| Compressive Strength | MPa | 2100 | ||

| Flexural Strength | MPa | 335 | ||

| Hardness (Vickers) | GPa | 11 | ||

| Hardness (Knoop 100 g) | Kg/mm2 | 1170 | ||

AlN/Aluminum nitride physical properties

ALN

| Name | AlN/Aluminum nitride | |||

| Maximum Temperature | Oxidizing | 750°C | Inert | 1300°C |

| Thermal Conductivity | @ 25°C | 180W/mK | @ 300°C | 130W/mK |

| Specific Heat | 760J/kg.K | |||

| Thermal Shock Resistance ΔT | 400°C | |||

| Coefficient of Expansion(10^-6/°C) | CTE 25°C ➞ 300°C | 4.6 | CTE 25°C ➞ 1000°C | 5.6 |

| Dielectric Constant | 8.6 (1 MHz) | |||

| Loss Tangent | 5×10^-4(1 MHz) | |||

| Volume Resistivity | 25°C | >10^13Ω cm | 500°C | 10^7Ω cm |

* Note –AlN/Aluminum nitride will form an oxide film on its surface at high temperatures, which can protect aluminum nitride. (The thermal conductivity of alumina is 30 W/m.K), the oxygen atmosphere is 750°C, and the inert gas protective atmosphere is 1350°C.

Why choose us, our AlN advantages

We focus on the manufacturing and sales of various engineering ceramic products, including alumina ceramics, boron nitride ceramics, silicon nitride ceramics, and more, which are widely applied in industries such as machinery, chemical, aerospace, and others.

Our customers are spread across the globe and encompass multiple industries, including machinery manufacturing, electronics and electrical, chemical production, medical instruments, aerospace, and more. We have established close cooperative relationships with numerous domestic and international enterprises and research institutions, working together to drive innovation and application of engineering ceramic technology.

Regarding our products, we always adhere to the principle of quality first and customer foremost. We emphasize technological innovation and team collaboration, dedicating ourselves to providing customers with the highest quality products and services.

Alumina Nitride Ceramic For Different Industries

AlN ceramics are widely used across various fields including electronics, chemical industry, mechanical engineering, medical devices, research, and laboratory settings.

Mechanical Engineering

In mechanical engineering, aluminum nitride ceramics find applications in ceramic bearings, sliding components, cutting tools, abrasives, transmission parts, mechanical connectors, and more. Their superior hardness, wear resistance, and stability enable them to perform well in high-strength mechanical environments.

Electronic Devices

Ceramic materials generally integrate well with the electronics industry. Aluminum nitride ceramics are commonly used for heat dissipation substrates, packaging materials, electronic ceramics, and more, thanks to their good insulation and strong heat dissipation properties.

Chemical Industry

Aluminum nitride ceramics exhibit corrosion resistance and chemical stability, making them capable of maintaining excellent stability even in harsh chemical environments. They are often manufactured into linings for chemical equipment, valves, pipelines, and other components in the chemical industry.

Medical Devices

AlN ceramics also play a significant role in the field of medical devices. Their excellent biocompatibility makes them commonly used in artificial joints, dental restoration materials, surgical instruments, and other medical applications, making them an ideal material for medical purposes.

Aerospace

For aerospace applications, materials must withstand extreme weather conditions. The high temperature resistance and corrosion resistance of aluminum nitride ceramics make them ideal for manufacturing thermal structural components, thermal protection materials, engine components, and other aerospace materials.

One-Stop Aluminum Nitride Ceramic Parts Fabrication Services

15+ Years of Experience. High Precision and OEM Design. Professional R&D Team. Competitive Price.

Can AlN/aluminum nitride ceramics be customized?

If you have customization needs, just provide us with drawings, and our professional team will customize it for you according to your needs, and will also provide you with technical support and advice.

What is the matching of thermal expansion coefficient of aluminum nitride ceramics?

The thermal expansion coefficient of aluminum nitride ceramics is similar to that of many metal materials and other ceramic materials, so its bonding properties are very good. When combined with aluminum, copper, silicon, alumina and other materials, cracks caused by temperature changes are greatly reduced. Reduced, it is one of the ideal materials in many high-temperature industrial fields.

How does the thermal conductivity of aluminum nitride compare with that of metallic aluminum?

Aluminum nitride ceramics have excellent thermal conductivity, have a higher thermal conductivity than metallic aluminum, and have very uniform thermal conductivity, which can transfer heat evenly and reduce heat loss.

Is aluminum nitride excellent in electrical insulation?

Aluminum nitride ceramics are also excellent insulating materials. Its crystal structure is very tight and it is difficult for electrons to move freely in it. It can be used in insulating materials in the fields of electronics, semiconductors, and electricity. Moreover, aluminum nitride ceramics still have good stability in high-voltage and high-frequency environments, which can effectively prevent current leakage and ensure the stable operation of electrical equipment. They are also often used in high-frequency electronic devices, In electrical components such as radio frequency devices.

Is aluminum nitride magnetic?

Aluminum nitride ceramic is a non-magnetic material, so it is suitable for applications where non-magnetic materials are required, such as magnetic resonance imaging equipment.