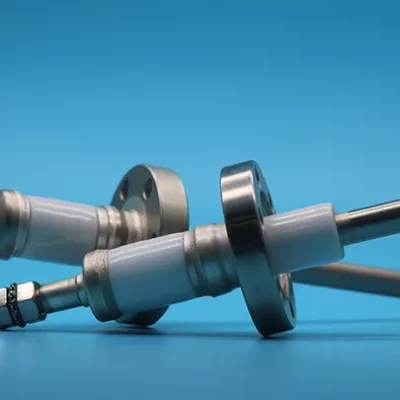

Solve your vacuum feedthrough needs

Not all applications can be solved with standard vacuum feedthroughs, so we offer you custom vacuum feedthroughs based on your specific needs.

Professional team service:

We have an experienced team of professional engineers who can customize vacuum feedthroughs for the most complex requirements.

Quick response:

Our streamlined customization process ensures that you receive quotes, design iterations, and final product solutions in a timely manner, minimizing your waiting time.

Transparent cost accounting:

We give you the most transparent pricing and cost estimates, allowing you to get the best products with the least amount of money!

Quality assurance:

We have a strict product control process to ensure that every customized vacuum feedthrough meets the highest standards of the industry, meets your specific performance needs, and provides reliable life expectations.

Welding details

Excellent after-sales service:

At GOGEROUS, we focus on long-term cooperation and value our customers. You don’t have to worry about after-sales problems. Our entire team is always here to solve your doubts and provide the best solutions.

Providing more than just products:

In addition to a comprehensive range of standard and custom vacuum feedthroughs, we also provide a wealth of technical resources and support to help you understand and optimize the performance of your vacuum system. Our experts can assist you with installation guidance to ensure that our feedthroughs are successfully installed in your specific settings.

Contact GOGRGOUS Today!

Let our team of experts help you design and manufacture the perfect custom vacuum feedthrough solution for your unique application. Contact GOGRGOUS today to discuss your requirements and experience the difference.

We look forward to partnering with you!