Structural Ceramics is well acclaimed for its futuristic benefits. It brings lot of demanding properties such as enhanced thermal mechanical and chemical properties. They find place in applications of aerospace, metallurgy, engineering, optics and material science. Indeed, what makes special structure Ceramics distinct and versatile is what is discussed here.

What are Special Ceramics?

Special Ceramics are generally nonmetallic in its constitution known for their strength, durability and resistance. Special Ceramics often cater in areas that are highly demanding where the other systems malfunctions or fails. The common special Ceramics are Oxide Ceramics such as Alumina, SiC, Si3N4 and carbides made up of Niobidium and Hafnium. Special Ceramics holds high mechanical integrity subject to harsh environments.

Some examples of Special Ceramics and the contexts of usage are given below for reference:

- Alumina Oxide a common oxide ceramic caters in the manufacture of medical devices and is useful in electronic applications

- Silicon Carbide is hard. The property of hardness and superior thermal conductivity makes them suitable for automobile and aerospace applications

- Nitrides of Silicon are wear and tear resistant. They become an integral part of cutting blades and mechanical bearings.

- Carbides of Niobidium and Hafnium is used in extreme temperature. The ceramic material is hence suitable in military, defense or aerospace applications.

Hardness of ceramic materials

Ceramic hardness is a term that stands for the ceramic and its resistance to any abrasion. This will tell us if the ceramic is able to withstand the effects of pressure, friction and indentation during usage. The special ceramics that are hard actively contribute as components for cutting tools, engine accessories and materials used during construction.

Ceramic hardness in Mohs scale

Ceramic hardness Mohs scale is used by engineers to estimate the hardness of ceramic. Indeed, the scratch resistance of a ceramic material. It generates value between 1 to 10. In short, the harder material scratches and creates impression on the softer counterpart.

- Alumina ceramic hardness in Mohs scale is 9. It stands next to that of diamond and is used as abrasives and cutting materials.

- Silicon Carbide (SiC) ceramic hardness reads 9.5. They are extremely useful as abrasives and used in the manufacture of bullet proof vests. It is the hardest ceramic material.

- Carbides of Niobidium and Hafnium both have ceramic hardness around 9 making them ideal for applications subjected to wear and Tear. They are also deployed in military and aerospace sections.

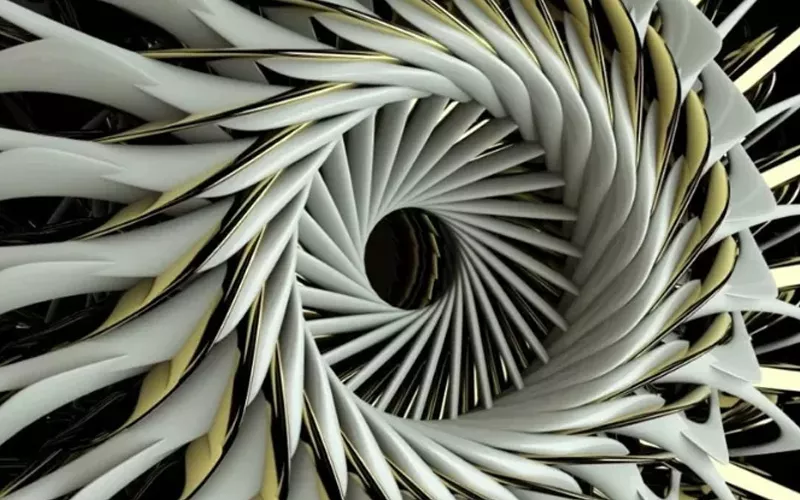

- Silicon Nitride has ceramic hardness mohs value around 8.5. They are majorly used n turbine blades and mechanical bearings which is a subject to high tear and wear.

Thermal conductivity of ceramic materials

Ceramic thermal conductivity is low for special ceramics. Some reliable thermal conductivity information is for reference.

- Thermal conductivity of aluminum Oxide is around 30 W/mK making it useful for thermal insulation and heat dissipation in devices.

- Ceramic heat conductivity of SiC is much higher when compared with the other ceramics. SiC register high heat conductivity in the range of 120 – 150 W/mK. This makes them useful in automotive applications and aerospace sector. SiC falls in the regime of high heat conductivity materials.

- Silicon Nitride possesses moderate thermal conductivity like alumina. Around 30-40 W/Mk is their range and makes them useful in moderate applications.

- Hafnium and Niobidium has the thermal conductivity in the range of 13 to 20 W/mK. They are basically engineered for rocket science and nuclear applications.

Properties of special Ceramic materials

Be it any ceramic material, the properties are majorly influenced by two factors. One is the chemical bonding present in the material and the other one the essential crystal structure. The other influencing factors are the micro composition, the grain structure, size, shape and porosity. The impurities and the defects during manufacturing also plays its role in controlling the behaviors of the special ceramic materials.

The conventional ceramic is feldspar, clay etc. that are basically prepared by sintering. They offer a temperature operating range of around 1200 degC. Although they are hard and are resistant to rust and corrosion, they lack benefits of superior thermal and mechanical strength.

Special Ceramics are distinct in their own way. For instance, lithium Oxide is highly heat resistant and are used for the manufacture of high temperature materials. Iron based Ceramics are used particularly as magnets, Talc for insulation and Cobalt based for memory components. Special Ceramics or special structural Ceramics are hence made as per the requirement and sought functionality are thoroughly engineered.

Structure of Ceramic materials

As mentioned, the properties of the ceramic materials are largely influenced by their structures. Basically, Ceramics have two major structures: either they are ionic in nature or Covalent. Ionic bonds impart electronegativity and make the nucleus attract more electrons. This works in combining metals and non-metals in ceramic.

Covalent bonds on contrary, exist between the nonmetals. This makes the material share the atoms in between each other. The low thermal expansion values, high hardness and chemical resistance are subject to the nature of bonds in ceramics. Brittleness although unforeseen also is a result of the bond nature.

Special structure Ceramics

Special structure ceramics has emerged in recent years and plays crucial role in Engineering. Structural ceramics are often a result of strict manufacturing backed by strong engineering to engage relevant material properties for entities.

Some special structure ceramics of importance

Nitride ceramics

Nitride ceramics has strong covalent bonds of Nitrogen and Silicon that provides better insulation and good strength. Silicon Nitride because of its structural merits forms one among the hardest ceramic material. It has superior corrosion resistance and acts as good insulating material. The thermal conductivity of Silicon Nitride is around 320 W/Mk

The thermal conductivity is hence 80 % superior to that of copper. Silicon Nitride also outsmarts ceramics such as Beo and Al2o3 in its performance.

Carbide ceramics

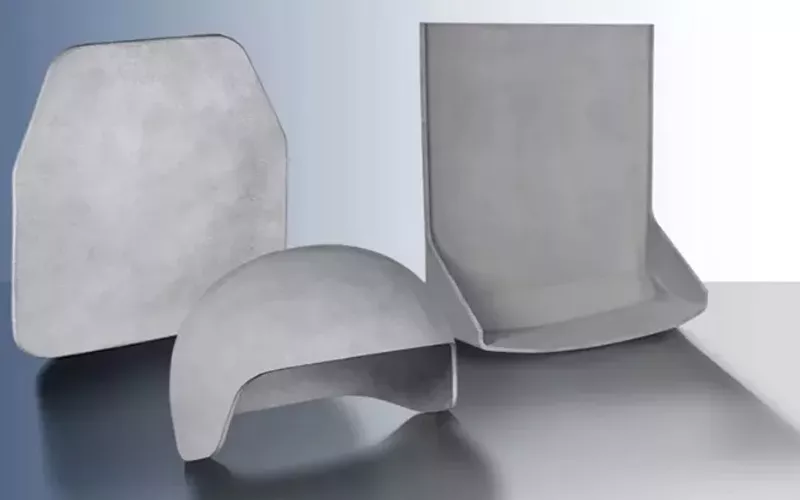

Carbide ceramics of Boron and Silicon possesses supreme bending strength. The value is around 500- 600 MPa at a temperature range of 1400 degC. The composite developed with both this carbides merits in providing high impact strength and high hardness. They also possess high modulus and are used in the production of vests or armors.

Toughened ceramics

Toughened ceramics has made great progress lately. There are toughened ceramics made of Alumina, Thorium and mullite and some made of oxides

Crystalline ceramics

The property of light transmittance additional to corrosion and chemical resistance has given rise to crystalline ceramics. The transparent ceramics made of alumina and Nitrides of alumina are popular in this regime. Manufacturers use microwave sintering to produce the crystalline ceramics.

Applications of special structure ceramics

- Structural ceramics due to its property to withstand high temperature they are often used in space ships and rockets. Ex: Composites is used in satellites

- Fiber reinforced ceramics or structural ceramics are used in subsonic aircrafts for military applications

- The high thermal conductivity of structural ceramics has resulted in using the same for circuit boards. They serve as efficient substrates

Concluding remarks

Exploration into Special structure ceramics occurred due to the inventions in modern science and technology. They possess functionalities both mechanical and thermal. They also outsmart in electrical benefits. Structural ceramics are already used in distinct areas of engineering. The future would of course rely on more advancements in this field.