Silicon nitride is an exceptional ceramic material with particular properties and applications in modern industries. Among these, the most impactful applications are found in the automotive industry, aerospace engineering, bearing manufacturing, electronics, biomedical, and dental implants.

Si3N4 has made many pieces of equipment and machinery more efficient and longer-lasting than before.

In this article, we will discover the uses of silicon nitride in modern industries. Let’s dive in.

What is Silicon Nitride?

Silicon nitride(Si3N4) is a chemically inert, thermodynamically stable, solid, white color, non-metallic ceramic material. It is produced by the chemical reaction of powdered silicon kept in a nitrogen atmosphere at around 1400 degrees Celsius. The chemical reaction that occurred in silicon nitride is:

3Si+ 2N2= Si3N4

Different types of silicon nitride-based materials are used for different purposes. Each of them has different properties and performance. The following are some of the mostly used forms of Si3N4 materials:

-

RBSN (reaction-bonded silicon nitride)

-

HPSN (hot-pressed silicon nitride )

-

SRBSN (sintered reaction-bonded silicon nitride)

-

SSN(sintered silicon nitride)

-

PSSN(partial pressure sintered silicon nitride)

-

and HIPSN (hot isostatically pressed silicon nitride).

Key Silicon Nitride(Si3N4) Properties: The Si3N4 ceramic element has many remarkable properties that make it suitable for various high-performance engineering and industrial applications. The major silicon nitride properties are:

-

Low density of around 3.21 g/cm3

-

High mechanical strength

-

High fracture toughness of around 7 MPam1/2

-

High thermal shock resistance near 569 K

-

Excellent thermal stability and wear resistance

-

Low coefficient of thermal expansion

-

Superior thermal shock resistance

-

Good oxidation resistance

-

And superior fracture toughness.

Top Silicon Nitride Uses in Modern Industries:

-

Engine Manufacturing: Silicon nitride is used widely in manufacturing different reciprocating engines, spark-ignited engines, automobile engines, and diesel engines.

Various engine parts are also made from it, such as diesel engine glow plugs, pre-combustion chambers(or swirl chambers), turbochargers, spark-ignited engine rocker arm pads, and exhaust gas control valves.

-

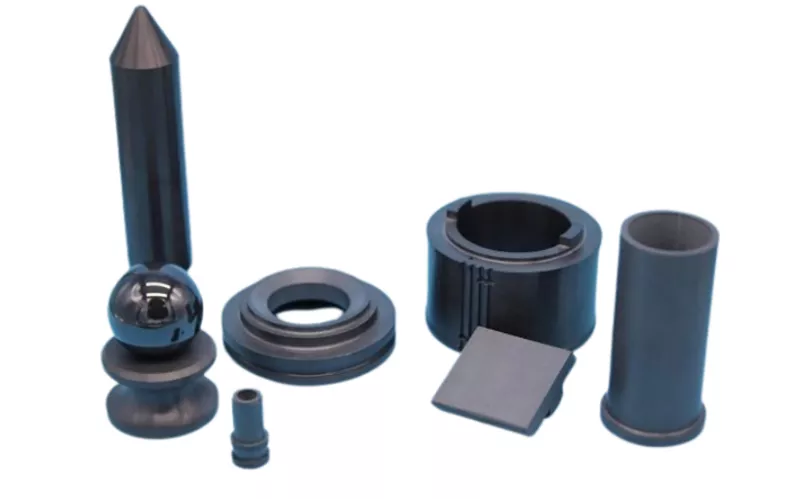

Bearings Industry: The fully densified silicon nitride material is wear-resistant, smooth, highly stiff, and stable in high temperatures.

Hence, the HPSN(hot-pressed silicon nitride) is commonly used in bearing production. These dense Si3N4s boost the operational performance of lubrication-less ball bearings and roller bearings.

The Si3N4 ceramic-made bearing is not affected by electric fields, magnetic fields, or corrosion. These bearings are long-lasting, highly corrosion-resistant, and fast like steel bearings.

Most Si3N4-made bearings are hybrid ball bearings with steel races and ceramic balls. These hybrid bearings are used for vacuum pumps, dental drills, and machine tool spindles.

-

Aerospace Industry: Conventional materials like composites and metals have been used in aircraft production for a long time. Those materials are not sustainable in extreme temperatures, pressure, and corrosion of hypersonic flight vehicles.

For this reason, the advanced aerospace industry requires more robust, lightweight, high-strength, corrosion-resistant, temperature-resistant materials such as ceramic silicon nitride.

It is an essential in the manufacturing of engines, thrusters, missile components, fuel systems, RF windows, ball bearings, and radomes of aircraft.

-

Electronic Appliances Manufacturing: Silicon nitride material has wide applications in the electronics and microelectronics industries. It is mostly used as a chemical barrier and insulator in different electronic appliances.

Si3N4 is an essential element of Integrated Circuits (ICs) and the protective packaging of highly sensitive electronic devices.

Silicon nitride works as a passive layer and diffusion barrier in microelectronic devices. It is employed as an electrical insulator in the capacitors of the analog chip.

Silicon nitride has a broadband nature. That is why it has applications in optical signal processing, biochemical and biomedical optics, biophotonics, data communication, and telecommunication.

-

Welding Industry: Silicon nitride has numerous uses in the electric resistance welding industry to fabricate welding rollers, replacing traditional steel. The extreme hardness, strength, and thermal shock resistance have made it an essential material for this industry.

-

Biomedical Industry: Silicon nitride is an ideal material for biomedical use due to its biocompatibility, anti-bacterial characteristics, chemical sterilization, radiolucency, lightweight, wear and corrosion resistance, and mechanical strength.

Silicon nitride has no side effects when implemented in the human body due to its biocompatibility. Its resistance to biofilm formation and bacterial growth prevents infections around the implants.

The osteoconductivity of silicon nitride forms the bone. Hence, it is used in dental, orthopedic implants, wound care, and fracture fixation devices.

Silicon nitride is used as a replacement for the spine and joints. Its exceptional mechanical strength allows it to take high stresses and heavy loads.

-

Biosensor: The superior mechanical and electrical properties of silicon nitride have made it an excellent material for the biosensor industry.

Its use in biosensor technology has solved many problems associated with the sensitivity, stability, and size of optical biosensors. It can further develop the efficacy of in vivo and in vitro diagnostics.

-

Dental Uses: The American Ceramic Society has referred to silicon nitride as the “killer ceramic material” for its antibacterial characteristics. It suppresses Porphyromonas gingivalis bacteria created in the oral cavities. These bacteria are the cause of gum disease.

The chemical stability of the silicon nitride dental elements resists their degradation in the oral environment from saliva, acids, and other chemicals. They don’t react or corrode like materials, which ensures longevity.

Si3N4 breaks the biological structure of bacteria and destroys the molecules, DNA, and proteins of the cells.

It is used to fabricate prosthetic crowns, dental implants, and root canal strengthening elements. The silicon nitride-made dental crowns, bridges, and veneers look like a real tooth. These Si3N4-made dental implants can tolerate repeated friction with other teeth and mechanical stress.

-

Possible Future Uses: Ceramic silicon has many possibilities in various industries. The most likely fields are advanced aerospace applications, nuclear energy, healthcare, biomedicine, high-power electronics, electric vehicles, renewable energy, and 3D printing.

More extensive research and development on silicon nitride materials will make that use possible soon.

FAQs

Q1: What is the use of silicon nitride in CMOS fabrication?

Silicon nitride is used as the dielectric layer, oxidation barrier, passivation layer, etch stop layer, stress engineering, spacer, and hard mask in CMOS (Complementary Metal-Oxide-Semiconductor) fabrication.

Q2: What is the work function of silicon nitride?

The work function of a material is the minimum energy required to move an electron from the material’s surface. The work function of the silicon nitride is not fixed and varies between 4.2 eV to 5.2 eV. It varies depending on the manufacturing environment and the materialistic properties.

Q3: What are the uses of nitride?

Nitride materials are widely used for their chemical resistance, high hardness, and thermal stability.

These nitrides are used in electronics, semiconductors, abrasives, cutting tools, protective coatings, light-emitting devices, aerospace, and the automotive industry.

Q4: What is the density of silicon nitride?

The density of silicon nitride is 3.17 g/cm3 (grams per cubic centimeter). It can vary between 2.37 to 3.25 g/cm3 for the production process. The density of the Si3N4 is an important parameter for many applications, such as nuclear physics.

Conclusion: So, friends, it’s time to sum up! We have discussed the important uses of silicon nitride in different fields. I hope you enjoyed reading the article and gathered the knowledge that will assist in your professional career.

Please stay connected with us to continue learning about important ceramic materials, their properties, and applications. Thank you