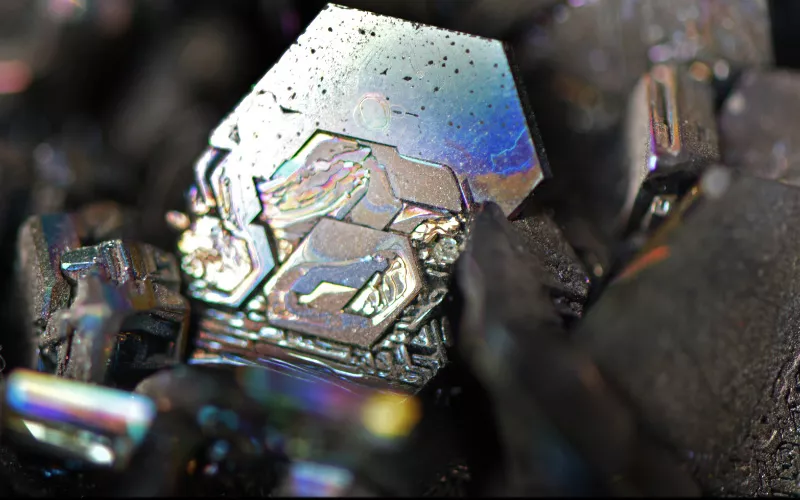

In very competitive industries, materials cannot simply be there to fulfill their minimal needs. They are required to give accuracy under extreme pressure. Silicon carbide plates do that. These high-tech ceramics work very well in places where they do not have a possibility of failure. Their high strength, thermal stability and chemical resistance are unmatched, be it in semiconductors, defense armor even down to nanoparticles.

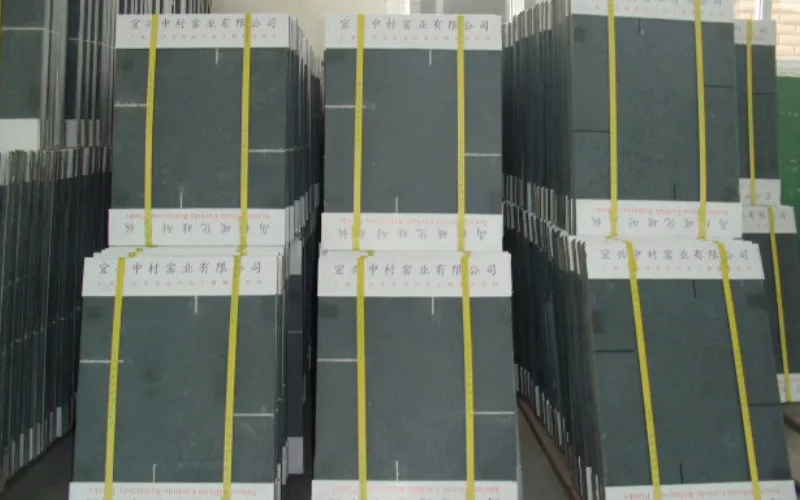

Silicon Carbide Plates

The silicon carbide plates give unmatched high performance under adverse conditions. These super hard ceramics provide contamination-free environments (<0.1 ppm) of semiconductor wafers with high ±1 o C temperature stability. Chemical plants have the advantages of having resisted sulfuric acid during the past 10 years and having the capacity to resist very fast 25 m/s fluid flow.

Their capability to prevent a bullet half the weight of steel is exploited in military applications and are accredited to resist 7.62mm bullets and IEDs. They are produced in standard sizes (100x100mm to 600x1200mm, 1-30mm thick), or custom shapes such as rocket nozzles, in three specialized grades: ultrapure CVD (99.9995%) suitable to thermal applications, high-strength sintered (450 MPa) to mechanical loads and corrosion-resistant nitride-bonded to harsh chemical environments.

Key Performance Specs

Going even deeper, silicon carbide plates have an extremely strong set of properties which make them unique:

|

Property |

Value |

|

Hardness |

~9.5 on Mohs scale |

|

Max Operating Temp |

1600–2000°C |

|

Thermal Conductivity |

120–200 W/m·K |

|

Purity |

Up to 99.8% |

|

Chemical Stability |

Inert in acids and gases |

All these qualities make SiC plates a leading solution among engineers who cannot risk material breakdown. They have an unrivaled advantage in high-performance, clean environments due to the combination of mechanical strength, thermal reliability and purity.

Industrial Applications

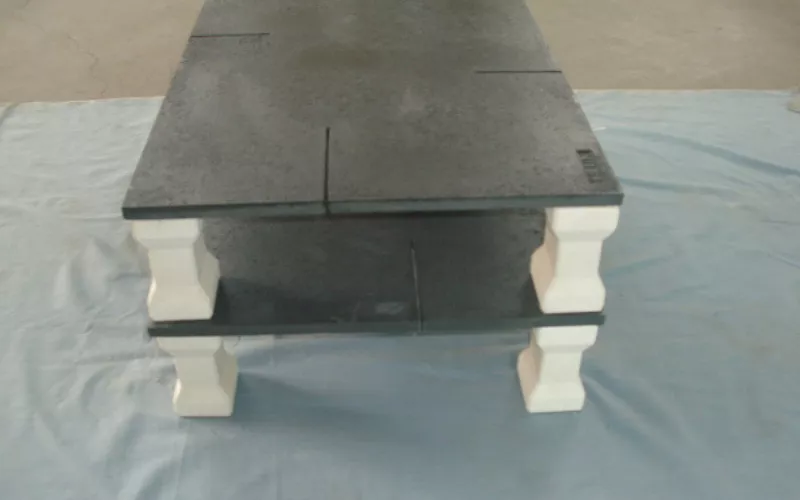

In a scenario where failure is not acceptable, silicon carbide plates are the most reliable ones. These advanced ceramic components find application in the most critical thermal and mechanical applications within the most critical industries.

Armor Applications

-

Lightweight armor-piercing-resistant armor through which armor-piercing bullets could penetrate.

-

One of the fundamentals of modern mobile warfare system.

-

Relied upon in body armor, armored vehicles and aircraft protection.

Semiconductor Manufacturing:

-

High purity wafer carriers and susceptors do not get contaminated.

-

Vacuum chamber linings make defect-free chip production possible.

Industrial Solutions:

-

Chemical plants: They are able to evaporate concentrated acids and subject themselves to immense crushing pressures that your everyday plain materials would wipe into oblivion.

-

Tremendous heat: Able to withstand temperatures of between 0 o C to 2700 o C without cracking, are also optimum kilns and furnaces.

-

Ironclad protection: Win the war on all other brands that can suffer simultaneously by being exposed to both extremely high temperatures and corrosion.

The Reason Silicon Carbide Performs Better than Other Materials

To have a clearer understanding of how valuable silicon carbide is, it is good to compare it with other ceramic materials that are widely used:

|

Material |

Max Temp (°C) |

Hardness |

Reactivity |

|

Silicon Carbide |

~2000 |

Very High |

Inert |

|

Alumina |

~1650 |

Moderate |

Slight reactivity |

|

Zirconia |

~1500 |

High |

Stable |

|

Boron Carbide |

~2200 |

Ultra-High |

Reactive under stress |

Choosing the Right SiC Plate

Selecting a silicon carbide plate is more than selecting a part off a catalog. Some of the most important considerations in the selection process are listed below in a checklist:

-

Operating Environment: Find out what the plate is going to have to operate in. Will it be subject to high vacuum, or corrosive chemicals or uneven temperatures in open air? Select a grade of SiC with design strength to cope with those extremes. The performance and service life will be affected by the environmental compatibility.

-

Geometry: Do you need a standard sized sheet of silicon carbide or a component of a specific shape with specified grooves, holes or cut-outs? The shape has to accommodate the design of your system.

-

Purity: Find out what is required in terms of purity in your application. Some of the areas that require high levels of purity to avoid contamination include semiconductors and medical fields.

-

Thermal Load: Get to know the temperature span that is required of your application. Will the plate come under the influence of intense and continuous heat? Make sure it can withstand the anticipated thermal stress without degrading / distorting.

-

Mechanical Integration: Get acquainted with the way the plate is to be installed. Will it be bolted, clamped, brazed or modular assembled? There should be some mechanical aid to the thermal and structural integrity of the plate by the mounting mechanism itself.

Maintenance and Durability

As far as the future is concerned, long-term durability is equally important as the performance. Silicon carbide plates have an outstanding long life span, which is not by chance. Handling, maintenance and environmental management are very big factors in maximizing their life span. The following are some of the key practices to make sure that your silicon carbide plates are able to deliver:

-

Clean often: Wash away residue, build-up or chemical deposits to ensure performance and avoid wear out prematurely.

-

Check visually: Discoloration, surface wear or cracks are to be checked. The small cracks are able to expand and must be dealt with at an early stage.

-

Environmental control: During a corrosive environment or high pressure environment, take special note of the environment around to prevent a surprise damage or failure.

When handled correctly, silicon carbide plates will last up to three times longer than metal or other lower-quality ceramic plates. They exhibit excellent thermal and chemical resistance and thus are stable and dependable even after thousands of operating cycles. This would result in less replacement parts, less downtime and long-term cost savings.

Case Study

One of the European semiconductor makers was reporting fundamental failures in their aluminum nitride structures:

-

It was noted that the plate fracture due to the thermal stress was reported after every 120 -150 cycles.

-

Contamination events lost comes at a cost of 2.8M in ruined wafers every year.

-

The production capacity was devoured by 15% of unexpected shutdowns.

The Solution

The replacement of the plates with silicon carbide plates gave the company the following results:

-

35% increase in the yields of wafers due to contamination -free processing.

-

Equipment uptime was doubled and life cycle to 800+ cycles.

-

The costs of maintenance were cut by 60% (420K to 168K/ per year).

What you stand to gain:

-

Steady temperature control: 0.5 °C thermal stability, whereby it used to be 2.3 °C fluctuation.

-

Clean room integrity: That particulate was suppressed to below Class 3 ISO.

-

8 month payback and yearly savings of 3.1M Euros.

Conclusion

Silicon carbide plates are something more than a material: they are an advantage. They are becoming more applicable in the contemporary industry where engineers and procurement heads need reliability, purity, and thermal stability at extreme conditions. Such plates have measurable worth in defense armor and semiconductor fabrication, among others.

With the increase in performance standards, there is also the increase in the need of materials that are able to cope with such standards. Silicon carbide plates are capable of withstanding the heat involved in high temperature applications, upgrading clean rooms, and designing new-generation protection. Not only are they made to be durable, but they are made to enable the future.