Boron nitride crucible stands for specialized containers made up of Boron Nitride. The superior properties of Boron Nitride benefits Boron Nitride Crucible’s functionality. They exhibit high thermal stability, are electrically insulating and are corrosion resistant. Boron Nitride Crucibles are generally used in specialist application that requires performance at elevated temperature.

What is Boron Nitride? Is Boron Nitride a compound?

Boron Nitride Crucible is a representation of how functional Boron Nitride is, as an advanced Ceramic. In the era of modern science and Engineering, constitution of a material influences its usage. Before getting to know about the BN Crucible and its features, let us get familiarised with BN as a compound.

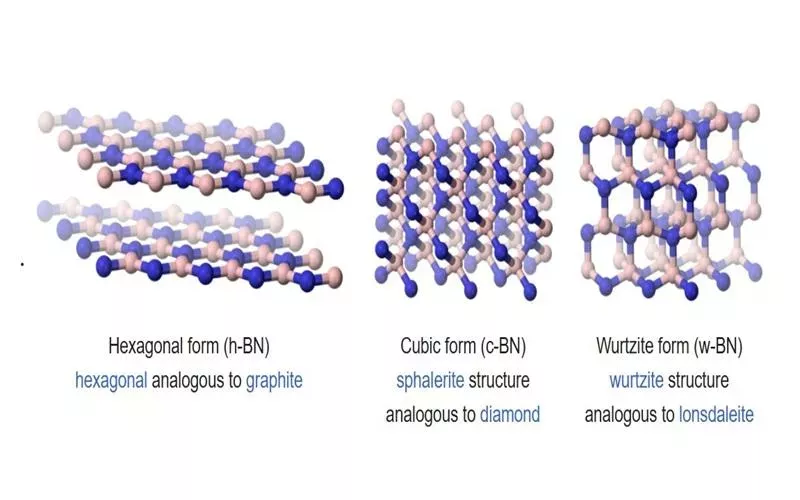

Boron nitride is a chemically and thermally stable advanced ceramic. It is a compound composed of boron and nitrogen with the chemical formula “BN” and usually exists in crystalline form with electrons isotropic to the carbon lattice.They are present in different structures such as Cubic, Amorphous, Hexagonal and Wurtzite.

Boron Nitride as an Advanced ceramic?

Boron Nitride is also known as “white graphene” as the structure of HBN is similar to the microstructure of graphite. However, contrary to graphite it has higher oxidation temperature and functions as excellent electrical materials. It is an advanced synthetic material that is available in solid and powder forms. Boron Nitride has also remarkable thermal workability around a temperature of 800 deg c.

Specification of Boron Nitride

A general property table is given below to discuss the behaviour of Boron Nitride as a Compound

|

Density of Boron Nitride |

1.9 g /cm3 |

|

Modulus of Elasticity |

27 G Pa |

|

Hardness |

2.26 G Pa |

|

Compressive Strength |

1433 MPa |

|

Dielectric Strength |

56 Kv/mm |

|

Volume Resistivity |

> 1013 ochm.cm |

|

Thermal Conductivity |

60 W/Mk |

|

Working temperature (Max) |

1800 degC |

Properties of Boron Nitride Crucible

Material knowledge is important with regard to the application and nature. The below given table, will help us to decide whether it is wise to use BN crucible for any application.

|

Purity of Boron Nitride Crucible |

> 99% |

|

Range of Density (g/cm3) |

1.94 – 2 |

|

Max Operating temperature in the presence of Inert gas (Argon / N2) |

900 |

|

Max Operating temperature in the presence of Air |

2100 |

|

Max Operating temperature in the presence of Vacuum |

2000 |

|

Compressive Strength (MPa) |

55 |

|

Flexural Strength (MPa) |

30 |

|

Thermal Conductivty (NTP) w/mK |

35 |

|

Coefficient of Thermal Expansion (10-6 /K) |

1.5 |

Types of Boron Nitride Crucibles

As discussed above, Boron Nitride crucibles are made by sintering and hot-pressing of boron nitride Powders. Different types of Boron Nitride crucibles with respect to the constitution or the material make are given below.

|

BN99 |

BN99 are made by hot pressing at high temperature around 900 degC. They offer purity of around 99 % and has high thermal conductivity and electrical resistance |

|

BNBO |

It is a kind of General-purpose material bonded with the help of Boric Oxide |

|

BN60 |

It has BN amount 60 % and SiO2 another 40% |

|

BN40 |

It has BN amount 40 % and SiO2 another 60% |

|

BNCB |

This is a type of Boron Nitride which is bonded with Calcium borate. It shows better moisture resistance |

|

ZSBN |

This composition has BN around 45% and Zr2O3 around 45% |

Advantages of Boron Nitride Crucible

The introduction of High-Performance Crucible has revolutionized industries such as material research and semiconductor processing. Metal melting has become a game changing experience with the introduction of BN crucibles. Major advantages of BN crucibles are highlighted below:

Superior Thermal Properties

Boron Nitride crucibles are most popular in applications such as sintering of ceramic, Metal melting and crystal growth. The performance of BN crucible in such application is attributed to their thermal stability. Boron Nitride Crucible can relatively function at a temperature maximum of 2000 degC without undergoing any structural changes.

Since the coefficient of thermal expansion is low, the constitution of BN crucible remains unchanged during rapid temperature changes. The thermal conductivity of BN crucible helps to dissipate heat uniformly through the system. These properties make the crucible ideal for application such as crystal growth.

In context where the material is expected to remain unaffected by thermal gradients, BN crucible are useful. The above distinct features of BN crucible help in better process control and temperature optimization

Electrical Insulation

The property of Electrical Insulation of BN crucible fetches its usefulness in the regime of semiconductor manufacturing. The excellent electrical insulating property of BN crucible avoid unnecessary electrochemical reactions at interfaces. The stoppage of interreference of electricity maintains the structural integrity of a material when processed in a BN crucible.

Easy Machinability and Customization

The easy machinability of Boron Nitride helps in manufacturing crucibles of different shapes and sizes. This contributes to the versatility of the structures made with the help of Boron Nitride Compound. The machinability makes the crucible to be manufactured as per the requirement. Boron Nitride can also be incorporated with certain other elements to improve the efficiency of the BN Crucible.

Hydrophobicity and Inertness

Boron Nitride crucibles exhibit excellent chemical inertness. It generally doesn’t interact with any materials for example Molten metals. For high temperature application this property of Boron Nitride Crucible helps us to maintain purity of the material being handled. It is generally employed in production of thin films, electronic component manufacturing and metallurgy.

Other relevant properties

Other than the above-mentioned properties, some other relevant merits of Boron Nitride Crucible are given below:

-

Boron Nitride crucible possesses low dielectric constant. The K value is in the range of 4. However, the dielectric strength is on higher side

-

The dielectric breaks down strength is high depicted in the range of > 40 KV/mm

-

Boron Nitride Crucible holds high electrical resistivity. However, the exemptions include ZSBN grade of BN Crucible

-

The material is of low density and are generally anisotropic. The thermal conductance of BN of parallel and perpendicular planes always differs.

Boron Nitride Crucible: Things to check

Boron Nitride crucible is generally crafted through hot pressing of BN powder and offers excellent purity. However special care should be taken while using the BN crucible in certain applications. Some of them are listed here for reference.

-

Boron Nitride Crucibles are to be used when the operating temperature is below 1000 degC. The usage of the BN crucible at a temperature above 1000 degC will cause oxidation of the BN. On contact with oxygen the surface of Boron Nitride Crucible gets peeled off due to severe degradation of the ceramic.

-

Since High Purity Boron Nitride absorbs moisture, it should be made sure the BN Crucible are not washed. However, the crucible can be cleaned by wiping it with alcohol or Sandpaper.

-

Certain Compounds causes degradation of the Boron Nitride Crucible. In such cases a chemically inert atmosphere has to be ensured to avoid progression of damage of BN Crucible. The compounds are trioxides, oxides of Antimony, Chromium, Arsenic and Titanium.

Applications of Boron Nitride Crucible

Perhaps Boorn Nitride is used in different applications because of its thermal stability at high temperatures. Of Course, excellent corrosion resistance and electrical resistance functions as supportive entities. Here in, we shall see some of the prominent applications of Boron Nitride crucible.

High temperature and corrosion specific applications

-

Boron Nitride Crucibles are used to handle materials in high temperature furnaces and vacuum furnaces. They are resistant to thermal shocks.

-

BN crucible is used to deal with molten metals for their property of high thermal resistance. This will help to sustain the purity of the metal being handled

-

BN crucibles are used for growing crystals

-

They are also used to aid ion injection requirement in any process

-

BN crucibles are used in processes such as ceramic sintering, to deal with melted alloys. It is also used on evaporation coating for handling electron beams

-

BN crucibles are used to break rings for casting machines

-

Boron Nitride crucibles function as integral spacers when it comes to glass melting applications

-

Boron Nitride Crucible are often used in oxygen sensitive applications

-

They are used in metal casting as Boron Nitride Crucible combines with metal to form interlayer metal boride or Nitride.

Electrical Applications

-

Boron Nitride Crucible are used as an integral part for electrical counterparts in furnaces or vacuum conditions

-

They are used to deal with high voltage equipments

-

BN Crucibles are used as substitutes in systems where graphite electrical conductivity intervenes in the overall efficiency of the system.

Packing of Boron Nitride Crucible

As boron nitride being a ceramic material, specialised packing inside carton boxes is generally envisaged for transportation. The BN crucible is packed in vacuum conditions in plastic bags and are secured with the help of foam. It should be ensured that the material undergoes no damage during transportation due to the improper handling.

Bottom Line

The introduction of Boron Nitride Crucible revolutionised high temperature applications in semiconductors, microelectronics and others. The property of advanced ceramic i.e. Boron Nitride has increased the functionality of Crucible made out of Boron Nitride. Boron Nitride Crucible ensures better process efficiency by keeping the material handled un-intervened by the Crucible.