Thermocouple Feedthrough Series: Bring 100% Perfect Application for Your Vacuum Application!

Are you struggling to find the perfect thermocouple feedthrough for your demanding vacuum application? GORGEOUS CERAMICS (GGS) customization can meet your needs! Our line of customizable thermocouple feedthroughs offers superior performance, unmatched reliability, and is perfect for your specific needs.

If you don’t find the thermocouple feedthrough you need, don’t worry, contact us now and we can provide you with the best custom solution.

Thermocouple Feedthrough Product Description

Type K Thermocouple Feedthrough - Micro Connector

|

Mounting Flange |

2.75’’ CF |

|

Thermocouple (T/C) Lead Diameter |

0.05 |

|

Number of T/C Pairs |

4 pairs |

|

T/C Type |

Type K |

Describe:

- Type: K-type thermocouple, 4 pairs

- Interface: Micro connector

- Flange specification: 2.75 inches (CF flange)

Feature:

- Integrated thermocouple for quick connection

- Ultra-high vacuum (UHV) compatible design

- Temperature up to 450°C, suitable for air and vacuum environments

- Complete connector assembly for air and vacuum sides

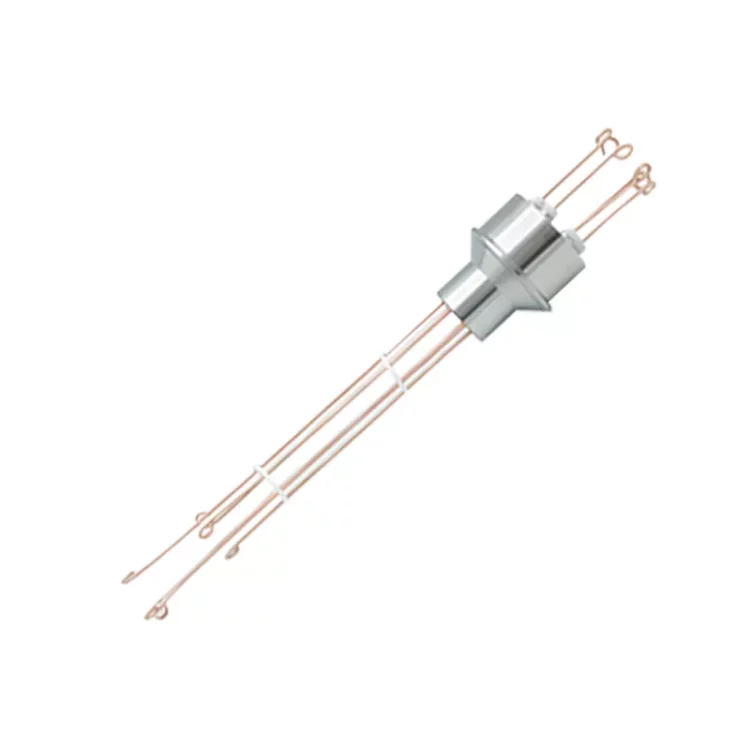

R-S Thermocouple Feedthrough - Screw Connector

|

Mounting Type |

Weldable (Custom Flange) |

|

T/C Lead Diameter |

0.05 |

|

Number of T/C Pairs |

3 pairs |

|

T/C Type |

R-S (Platinum-Rhodium) |

Describe:

- Type: R-S type thermocouple, 3 pairs

- Interface: Screw-type connector

- Adapter: 0.75 inch stainless steel welding type (UHV grade)

Feature:

- Rigid screw connection structure ensures contact reliability

- Ultra-high vacuum (UHV) compatible design

- Temperature up to 450°C

- Complete connection kit for vacuum flange side and atmosphere side

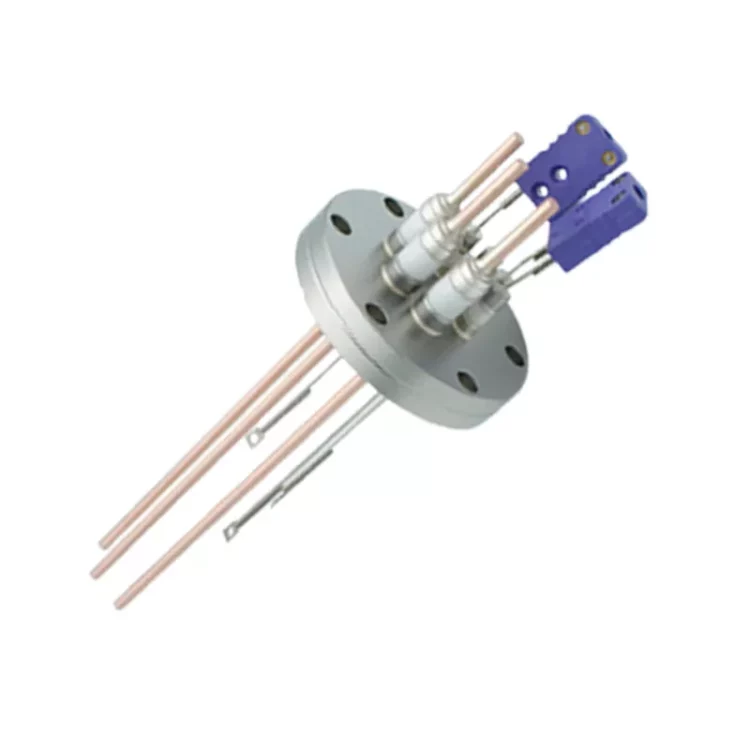

Type E Thermocouple Power Feedthrough - Micro TC Connector

|

Mounting Flange |

2.75” CF Flange |

|

Power Lead |

0.156’’ Copper conductors (for Thermocouple-Power Feedthroughs) |

|

T/C Lead Diameter |

0.05 |

|

Number of T/C Pairs |

2 pairs |

|

T/C Type |

Type E (Nickel-Chromium vs. Constantan) |

|

Voltage Rating |

5 KV |

Describe:

- Type: E-type thermocouple (2 pairs) + power supply composite type

- Interface: micro connector

- Power supply: 5000V/60A

- Flange specification: 2.75″ CF-F flat type

Feature:

- Reachable temperature 450℃ (bidirectional baking)

- Leak rate: <1×10⁻⁹ mbar·L/s (helium mass spectrometry detection)

- TC connector on vacuum side (customizable length)

- TC connector on atmosphere side (can be equipped with protective sleeve)

- Insulating protective cover for power interface

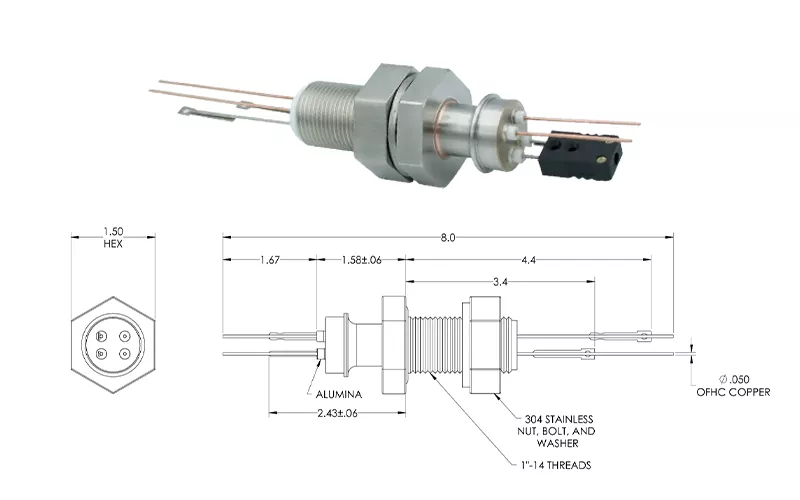

Thermocouple Power Feedthrough - with Micro TC Connector

|

Mounting |

1.00″ Base Plate |

|

Power Wire |

0.050″ Copper conductor |

|

T/C Lead Diameter |

0.05 |

|

Number of T/C Pairs |

1 pair |

|

T/C Type |

Type J (Iron-Constantan) |

Describe:

- Type: 1 pair J-type (with micro TC connector)

- Power supply: 1000V/25A (2-pin interface)

- Mounting method: 1″ flush mount base plate

Feature:

- Vacuum level: UHV compatible (leak rate <1×10⁻⁹ mbar·L/s)

- Available temperature: 450℃ (bidirectional baking)

- TC connector on the vacuum side (customizable cable length)

- Waterproof connector on the atmosphere side (IP67 level)

- Power terminal protection cover (anti-touch design)

Purpose of Thermocouple Feedthrough

- Vacuum chamber temperature monitoring

- Semiconductor equipment process control

- Particle accelerator system

- Space simulation device

- Nuclear fusion experimental device

- Molecular beam epitaxy equipment

- Ultra-high vacuum coating system

- Synchronous radiation source

- Low-temperature superconducting experiment

- Spacecraft thermal vacuum test

- Photovoltaic equipment manufacturing

- Electron beam welding equipment

- Mass spectrometer

- Crystal growth equipment

- Plasma research device