Ceramics were used to make pottery in ancient civilizations; now they are used in various fields. Different modern ceramics have sophisticated properties and applications.

Among them, structural ceramics are an important type used in the aerospace, medical, automotive, engineering, energy, and electronics sectors.

In this article, we will cover the applications of structural ceramics in modern industries. Let’s begin.

What is Structural Ceramics and Why Does it Matter?

Structural ceramics are the engineering-grade ceramic materials processed to manufacture cutting-edge machines, devices, tools, and vehicles.

Structural ceramics elements deliver stable performance in harsh conditions. They are popular for their high mechanical strength, thermal stability, excellent wear resistance, durability, and inertness.

Structural ceramics are lightweight yet strong. Their application significantly reduces the weight of machines and instruments.

These ceramic elements have applications in high-technology manufacturing where usual ceramics and metals cannot be used. They have made critical engineering fields such as mechanical, aerospace, and automobile more innovative.

Modern technology depends much on the exceptional characteristics and performance of structural ceramics.

Some Important Structural Ceramics Examples:

-

Alumina(Al2O3): Alumina is one of the most renowned structural ceramic materials. It is a white-colored material with some exceptional properties, including a high melting point, high strength, extreme hardness, thermal stability, wear resistance, and electrical conductivity.

Pure Al2O3 with its desired properties is found at a low cost. It is a refractory ceramic material typically used as an abrasive, insulator, and heating element.

-

Silicon Nitride(Si3N4): Si3N4 is a highly wear-resistant and thermally stable structural ceramic material. It is a black or dark grey material that can be polished to a shiny appearance.

-

Silicon Carbide(SiC): Silicon carbide is a black or greenish color material that has high corrosion resistance and hardness.

Silicon carbide can be fabricated into various extremely hard ceramic products, making it perfect for use in automotive components.

-

Zirconia(ZrO2): ZrO2 is a crystalline white oxide of zirconium. High thermal stability and superior thermal shock resistance are two vital properties of Zirconia.

It is an odorless, refractory ceramic, popularly used in oxygen sensors, plasma-sprayed coatings, and medical implants.

-

Boron Nitride(BN): Boron nitride consists of one boron and one nitrogen atom and forms a hexagonal structure like graphite by the binary covalent bonds. It has extreme insulation capacity, very high thermal conductivity, and high-temperature stability.

Boron nitride is found in solid and grain form with extreme hardness, similar to that of diamonds.

Uses of Structural Ceramics In Different Modern Industries:

-

Mechanical Engineering: Mechanical engineering is a complex technical sector where structural ceramics components play a vital role. Ceramic components show unparalleled precision and durability in mechanical machinery and equipment.

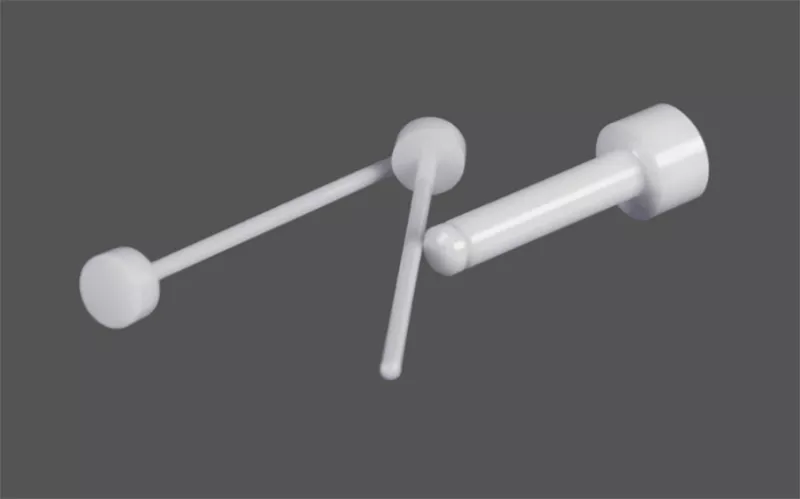

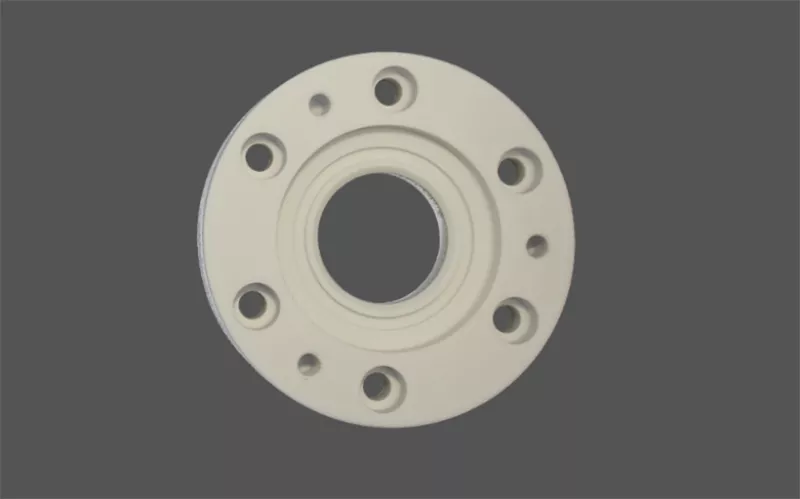

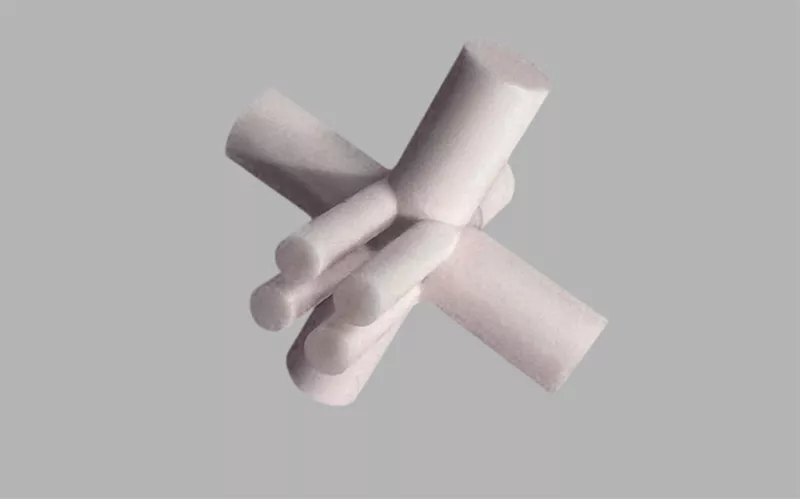

Some essential ceramic components used in mechanical engineering are ceramic rods, ceramic plungers, ceramic bushings, ceramic weld rollers, ceramic discs, ceramic pins, ceramic nozzles, and ceramic valves.

Structural ceramics also have huge applications in manufacturing machinery, cutting and grinding tools, wear-resistant components, thermal processing equipment, and chemical processing equipment.

Below are the common mechanical machinery made from structural ceramics:

-

Bearings and bushings

-

Seals and gaskets

-

Grinding wheels

-

Cutting inserts

-

Pump impeller and liners

-

Valve seats and balls

-

Kiln furniture

-

Heat exchangers

-

Filtering system

-

Reaction vessel, etc.

-

Aerospace: Structural ceramic materials are essential for the aerospace industry.

They are the key elements of an aircraft’s body, engine parts, and safety materials, and are typically used as Ceramic Matrix Composites(CMCs). These CMCs are stronger and tougher than a single ceramic material.

In aerospace, weight is a critical factor; structural ceramics reduce the overall vehicle weight and increase fuel efficiency.

-

Automotive: Structural ceramics have made automobiles high-performance in extreme conditions. They are the main elements of brake components, exhaust systems, and electronic items of modern automobiles.

The global automotive ceramics market is growing and is expected to reach a CAGR(Compounded Annual Growth Rate) of 6.3% by 2030.

-

Energy Department: The energy infrastructure and instruments require materials with high temperature stability and sustainability in challenging environmental conditions.

Structural ceramics facilitate the manufacturing of high-efficiency energy devices and structures for the energy sector. The following robust electrical and mechanical components are built with these ceramics:

-

Gas turbines,

-

Turbochargers,

-

Heat exchangers,

-

Exhaust systems,

-

Insulation devices,

-

Fuel cells and batteries,

-

Solar cells

-

Robots

-

Ceramic effectors

-

high-voltage insulators, relays, and sensors.

-

Chemical Industry: The chemical industry operates in a harsh environment where conventional materials often lack durability. Hence, the structural ceramics made equipment is vital for these factories.

The following are the key elements of chemical processing mills where advanced ceramic materials are found.

Chemical Reactors: Zirconia (ZrO2) and Silicon carbide (SiC) are two highly versatile structural ceramics with exceptional resistance to corrosion and chemicals. They are used to build chemical reactors where they withstand aggressive media and extreme temperatures.

Reactor Vessels and Lining: Ceramic components show high inertness in oxidizing conditions. They prevent chemical reactions and contamination in highly reactive chemical processing systems to assure operational integrity.

Pump and Valve Accessories: Structural ceramics are hard, abrasion-resistant, and durable. Hence, the valve parts and pumps are made of structural ceramic materials. They can achieve a longer lifespan in the toughest conditions of chemical factories.

-

Semiconductor Manufacturing: High-performance ceramics made into accessories have a wide range of applications in semiconductor manufacturing. They offer precision, reliability, and durability in the fabrication of delicate semiconductor devices and chips.

Alumina and silicon nitride are employed in the wafer carriers for polishing due to their hardness and wear resistance. They are also utilized in complex Integrated circuits ( IC) structures and semiconductor packaging.

-

Electronic Appliances: Electronic devices made of hard structural ceramics are more reliable and durable. Highly complex electronic frameworks require superior electrical and thermal qualities, often found in ceramic substrates.

Ceramic materials enabled innovative designs for electronic appliances.

Certain functional ceramic materials are essential components in high-frequency circuits of telecommunication and transmission systems.

Some other ceramic composites serve as electromagnetic shields for sensitive electronic systems and repel electromagnetic interference(EMI).

-

Medical Applications: Structural ceramics have a revolutionary impact on modern medical technology. They have taken medical treatment to a new height.

Electro-Medical Equipment: Different electromedical machines have structural ceramic-made components, such as:

-

high-performance alumina-made insulators in X-Ray imaging machines,

-

precise structure of ceramic-made electrodes and electrode supports in mass spectrometers,

-

ultra-pure alumina in blood testing machines,

-

accuracy pump components, etc.

Life Sciences: Several life-saving medical accessories are made from wear and corrosion-resistant structural ceramic materials, including fluid atomizers, sliding blood valves, and fluid dispensing nozzles.

Frequently Asked Questions:

Question: How are modern ceramics different from older traditional ceramics?

Answer: The main difference between modern ceramics and traditional ceramics is in their raw materials, processing, and properties.

Traditional ceramics are usually made from natural elements such as clay, minerals, and rocks.

But, the main constituents of modern ceramics are highly pure inorganic compounds, synthetic, and adhesives. They are synthesized in a rigorous synthesizing process of molding, sintering, and machining.

What are the industrial uses of ceramics?

The industrial uses of ceramics are in heat-resistant, wear-resistant spare parts, refractories, bearings, abrasives, cutting tools, etc.

Bottom Line: Therefore, the structural ceramics materials are an integral part of modern technology-based civilizations. They have applications from aerospace to household components, and the ceramic industry is expanding rapidly everywhere.

Structural ceramics are not just materials; they are an extraordinary architectural element that is enhancing our lives every day. The demand for these materials is exceeding the records with the advancement of technology.