Beryllium Oxide Substrate

GORGEOUS is a leading international ceramic supplier, specializing in providing customers with beryllium oxide substrate products and customized solutions for the manufacturing of high-power semiconductor devices and microwave and radio frequency devices.

High-Quality BeO Substrate

GORGEOUS offers high-purity beryllium oxide substrates (BeO substrates), as well as thin-film and thick-film metallized ceramic substrates.

Product Advantages:

Excellent thermal conductivity ensures excellent heat dissipation in high-power electronic applications.

High dielectric strength and insulation properties provide both electrical insulation and excellent thermal management.

Low dielectric constant and low dielectric loss make them suitable for high-frequency and microwave devices.

High dimensional stability minimizes warping, bending, or deformation.

Leading Global Manufacturer of Beryllium Oxide Substrate

GORGEOUS has over 15 years of expertise in high-performance ceramic substrate manufacturing, specializing in the manufacture and supply of beryllium oxide substrates.

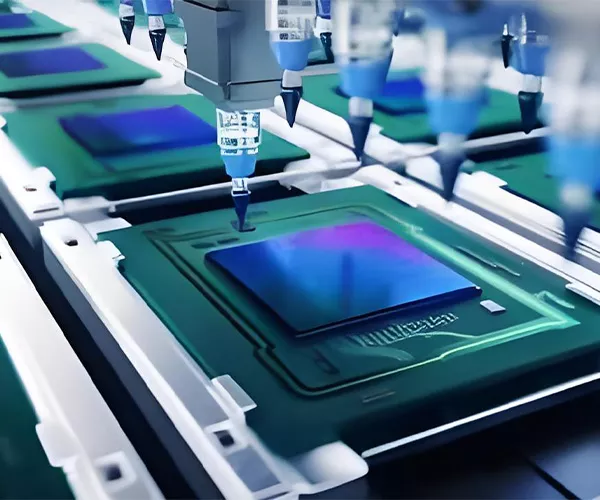

Our advanced production lines and testing equipment ensure that every substrate we produce meets the highest standards of precision, reliability, and thermal performance. From raw material processing to final inspection, every step is subject to rigorous quality control.

Our experienced team of engineers provides customized design support and technical guidance, helping customers optimize their solutions for improved performance and cost-effectiveness.

With GORGEOUS, you gain not only a supplier but also a trusted manufacturing partner capable of large-scale production and rapid delivery.

Beryllium Oxide Substrate Product Gallery

Basic Specifications of Beryllium Oxide Substrate

| Thickness | ≥0.254mm |

| Roughness (Ra) | 0.05-0.1μm(polishing) |

| Thermal Conductivity | 200-310W/mK |

| Dielectric Constant | 6.5-7.3@1MHZ |

Beryllium Oxide Substrate Applications

High-Power Semiconductor Device Packaging

Beryllium oxide substrates can be used as substrates for devices such as power transistors, IGBTs, and MOSFETs.

Because BeO has a thermal conductivity close to that of copper (200–260 W/m·K), it can quickly dissipate heat and ensure stable device operation at high power levels.

Microwave and RF Devices

Beryllium oxide substrates can be used in radar systems, satellite communications, and 5G RF modules.

BeO's low dielectric constant and low dielectric loss can reduce energy loss in high-frequency signals and improve transmission efficiency.

Optoelectronics and Laser Devices

Beryllium oxide substrates can be used as heat sinks for laser diodes (LDs), high-brightness LEDs, and infrared lasers.

Due to its high thermal conductivity and electrical insulation properties, beryllium oxide substrates ensure stable, long-term operation of optoelectronic devices at high power levels.

Aerospace and Military Electronics

BeO substrates can be used in missile radar systems, aerospace communications equipment, and high-energy weapon electronic modules.

BeO also maintains reliable performance in extreme environments such as high temperatures and strong radiation.

Medical Devices

Beryllium oxide substrates can be used in X-ray tubes, medical lasers, and radiotherapy equipment.

BeO's high thermal conductivity and insulation properties ensure the safe operation of medical electronic components under high voltage and high power conditions.

Are You Worried About the MOQ?

Our BeO substrates offer a special minimum order quantity (MOQ) of one piece to meet small order needs. Experience our service now.

Why Choose GORGEOUS?

At GORGEOUS, quality control is our top priority. Every beryllium oxide substrate is manufactured to our customers’ exacting specifications and undergoes extensive inspection and testing, from raw materials to finished product, to ensure consistent performance and reliable quality.

Our factory is certified to IATF 16949:2016 for the automotive industry and ISO 9001:2015 for international quality management systems. This not only demonstrates our commitment to quality, but also ensures we can provide our customers with high-standard customized solutions.

Our Pass Successes Testimonials

We are developing the next generation of high-power RF modules, which place extreme demands on the thermal conductivity and dielectric properties of ceramic substrates. The BeO substrate samples provided by GORGEOUS fully meet our theoretical design values.

James Walker

GORGEOUS demonstrated amazing flexibility and quick response when handling our orders, and the beryllium oxide substrates offered a very competitive price/performance ratio.

David

In terms of price and absolute quality reliability, GORGEOUS has done impeccable.

Christopher Johnson

FAQs

Can beryllium oxide ceramic substrates be customized for specific applications?

Yes, beryllium oxide ceramic substrates can be produced in a standardized manner. GORGEOUS also utilizes its expertise to provide in-depth customization based on customer needs, including size, shape, thickness, surface treatment, metallization, and structural design.

What are the manufacturing methods of beryllium oxide ceramic substrates?

There are many methods for manufacturing beryllium oxide ceramic substrates, including dry pressing, isostatic pressing, injection molding, tape casting, and hot pressing. Different processes address different application requirements.

What are the advantages of using beryllium oxide ceramic substrates?

The advantages of beryllium oxide ceramic substrates are mainly reflected in thermal conductivity, electrical insulation, high temperature resistance and other aspects. They are widely used in applications with extremely high requirements for thermal management and stability.