What is silicon nitride?

Silicon nitride is an advanced oxide ceramic material renowned for its high hardness, strength, and excellent thermal stability. Its applications span many specific industries, including modern automotive, aerospace, electronics, and medical.

In this article, GORGEOUS will provide a detailed overview of the uses of silicon nitride.

What Is Silicon Nitride?

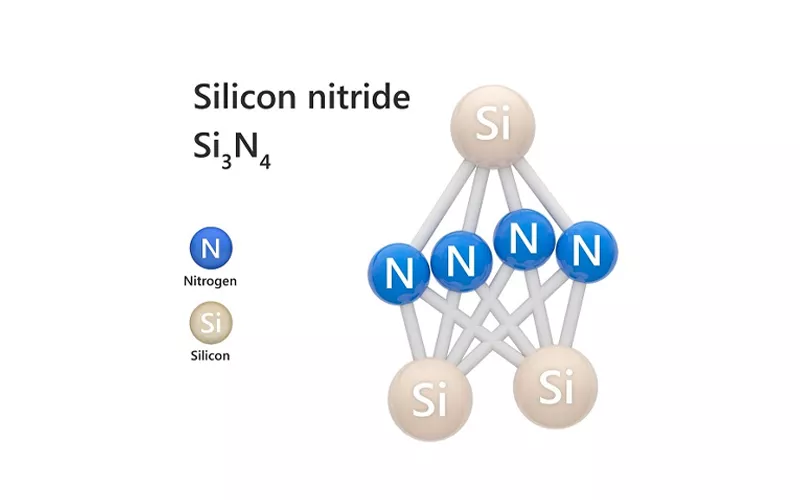

Silicon nitride, or Si₃N₄, is a non-oxide technical ceramic material formed by silicon and nitrogen. It is widely known to have very high hardness and thermal stability and high resistance to wear and corrosion.

Known for fifty years as a carbide with a high melting point and excellent mechanical, thermal, and electrical characteristics, Silicon Nitride has found its place in high-tech applications.

It is equally lightweight and strong, able to withstand high temperatures and mechanical pressure. There is a frequent use of silicon nitride in engineering where required features are high tensile strength and heat, friction and chemical resistance.

Because silicon nitride is chemically inert under high pressures and temperatures, it is suitable to fit high-level components in several sectors.

Silicon Nitride in Automotive Applications

Quite an important market for silicon nitride has been the automotive industry, particularly for parts used in high-revving engines and other components operating under high stress. In particular, silicon nitride uses include:

Turbocharger Rotors: Since silicon nitride is lightweight and highly strengthened, ceramic material is used to enhance fuel efficiency and improve engine response times.

Ball Bearings: Due to its low friction and high wear resistance, silicon nitride is commonly used in bearings for high-speed, high-stress applications, including electric motors and racing cars.

Glow Plugs: The life expectancy – it has a high heat resistance and is therefore suited for application for diesel engine glow plugs for improved performance in extremely cold temperatures.

These applications help improve the efficiency, durability, and performance of engines and, therefore, automobiles.

Applications in Aerospace and Defense

Silicon nitride is used in aerospace and defence applications since high strength-to-weight ratio materials are determined to be vital. The material is used in the following applications:

Aerospace Components: In applications such as turbine blades, engine parts, and other high-stress, high-temperature aerospace applications of silicon nitride excels due to its high-temperature strength.

Defense Systems: The material’s high wear resistance and thermal stability enable its application in ballistic protection and other defence applications that involve exposure to extreme conditions and/or mechanical stress.

Rocket Engine Components: It is important for rocket motor components because it has high strength and maintains its mechanical properties at high operating temperature; this saves on weight and increases the life of the component.

By the aerospace and defence industries, better use of silicon nitride results in lighter systems which lead to improved performance yet maintain strength and reliability.

Silicon Nitride in Electronics

The electronics industry has also realized the benefits of silicon nitride, which possesses very high electrical insulation. It is commonly used in:

Semiconductors: Silicon nitride finds application in both insulated as a dielectric material and passivated in semiconductor production to shield the electronics components from the surrounding environment.

Microelectromechanical Systems (MEMS): Due to its high microhardness and good performance at the micro level, silicon nitride is used effectively in MEMS devices and is widely used in the application of sensors and actuators.

LED Manufacturing: Silicon nitride is also widely applied as a barrier layer in the manufacture of LEDs to improve performance and durability.

In the electronics industry, silicon nitride lengthens device life, increases device performance, and facilitates protection against environmental factors.

Silicon Nitride in Medical Applications

Silicon nitride has fit itself nicely into the medical industry, for example, in the present day, implants and medical equipment. Its properties make it ideal for:

Medical Implants: Silicon nitride is biocompatible and has high strength characteristics and low wear and tear, so it is applicable in spinal implantation, joint replacements, and dental uses. It also shows the ability to kill bacteria, thereby preventing post-surgical infections.

Surgical Tools: Through the material’s ability to provide hardness and wear resistance, surgical instruments indicate greater endurance in precision cutting.

Increased application of silicon nitride material in the medical field has therefore promoted the development of more long-lasting and safe implants for patients.

Role in Industrial Applications

Nonetheless, silicon nitride is applied in many industrial facilities, especially where conditions are extreme. Silicon nitride in manufacturing and industrial applications include:

Cutting Tools: silicon nitride has high hardness and good thermal stability, and its application is in cutting tools used in manufacturing processes, including metal cutting and machining.

Bearings and Rollers: It is used to machine various tough products, bearings, and rollers in many machinery and equipment, resulting in low maintenance and frequent downtimes.

Kiln Furniture: In the ceramics industry, silicon nitride is used to create kiln furniture products in high-temperature and corrosive applications to optimize high-temperature processes.

This property makes it perform well and last longer in industries, it is not degraded when exposed to extreme conditions.

Emerging Uses of Silicon Nitride

As technology advances, new applications for silicon nitride are emerging in various fields:

Renewable Energy: It has anticipated the application of high mechanical strength and environmental endurance for application in solar power systems and wind turbines.

3D Printing: Further study is being done to explore the applications of the material in additive manufacturing, which helps create more complex shapes and parts with finer detail.

Advanced Coatings: Silicon nitride is still in the design stage as a coating agent in fields like oil and gas because of the unique characteristics of wear and corrosion.

Such upcoming applications demonstrate how silicon nitride may continue to grow its uses in modern innovative technologies.

Advantages of Silicon Nitride Over Other Materials

Silicon nitride offers several advantages over traditional materials like metals and other ceramics:

High Strength-to-Weight Ratio: This material offers an excellent, high strength-to-weight ratio, which in turn decreases the amount of material used, providing superior performance within applications like aerospace and automobile manufacturing.

Superior Wear Resistance: Silicon nitride has superior wear resistance to metals and other ceramics. Thus the components are able to operate for a longer period in a high wear environment.

Thermal Shock Resistance: Silicon nitride ceramics possess significantly greater heat resistance than most metals and do not crack under rapid heat cycling, ideal for high-temperature uses.

All these advantages make the silicon nitride material more cheaper and more reliable to use in demanding applications than other available materials.

Challenges in Using Silicon Nitride

Despite its many benefits, there are challenges associated with using silicon nitride:

Cost of Production: Silicon nitride products are relatively expensive to produce; thus, they are used where performance is paramount.

Brittleness: While silicon nitride is a powerful material and has other excellent properties, it is also rather brittle, which could make the material fail under specific impact or shock loads.

Complex Manufacturing: Silicon nitride is said to be manufactured using certain high-tech methods that are time-consuming and raise product prices.

Solving these problems will be crucial to the broader application of such materials as silicon nitride in different areas.

Conclusion

Silicon nitride’s superior properties make it a highly valuable material in many high-performance industries today. Whether in automotive structures, medical devices, or a wide variety of other applications, this material is becoming increasingly indispensable in advanced manufacturing and materials technology. Therefore, although research is still ongoing, silicon nitride shows great promise for development in many industries.

GORGEOUS is a professional supplier of silicon nitride ceramics, providing optimal customized solutions for customers across various industries.

FAQ

What are the applications of silicon nitride?

Silicon nitride ceramics are mainly used in automotive engines, bearings, semiconductors, medical implants, and cutting tools.

Is silicon nitride stronger and more durable than steel?

Yes, silicon nitride ceramics have a higher strength-to-weight ratio and are stronger than steel in terms of wear resistance and durability.

What are the advantages of using silicon nitride in bearings?

Silicon nitride is lighter, harder, and more corrosion-resistant than other ceramic materials, which can extend bearing life.

Can silicon nitride withstand high temperatures?

Yes, silicon nitride maintains its strength at temperatures exceeding 1000°C.