You probably think all ceramic tube manufacturers are basically the same. Years ago I had the same belief until I witnessed my first tube disaster. Such costly breakdowns do not involve only the cost of replacement parts but closure of whole production lines.

I will demonstrate to you precisely why some tubes have a shelf life of years and others break in weeks, and how to select suppliers that provide what they promise in performance.

What I Learned From Watching Companies Waste Money on Bad Tubes

When I first started working with alumina ceramic tubes 15 years ago, I made a costly mistake. I believed that the factor that matters most is price. And that erroneous thinking lost my company 50,000 in a quarter.

One facility after another kept repeating the mistake. They would purchase low cost industrial ceramic tubes and ceramic furnace tubes, and every 3-4 months replace them when they ought to last 18-24 months. The actual price is not only the tube, it is the lost time, expedited shipping, extra labor, and materials that make the difference and break the bank.

The 5 Tube Killers I See Over and Over

Over the years working with these materials I have studied more than 300 failures. This is what kills ceramic tubes:

a) Heat Shock: The Number One Killer

This destroys more alumina ceramic tubes than anything else. I recall that I was at a steel plant where they warmed up furnaces at a room temperature to 1400 o C within half an hour. Their ceramic furnace tubes were popping apart with loud pops about every few days. On an average, the maintenance manager was going bald with the monthly replacement costs amounting to 15000 dollars. It was an easy fix, the temperature could be raised slowly at 5C per minute, maximum and those failures were gone.

b) Wrong Material Grade Selection

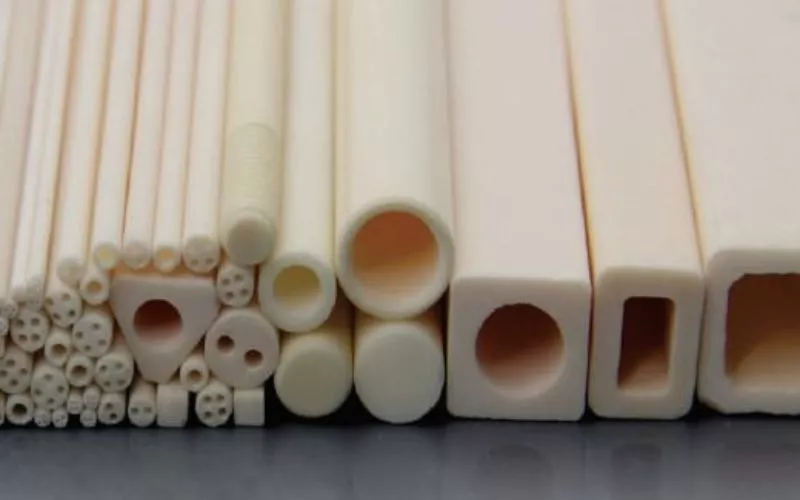

All of the tubes cannot take the same beating. I experienced it when a semiconductor customer found the use of 95 percent alumina tubes in a chemical vapor deposition process. They required 99.7 percent purity yet no one informed. The gases in the process ate away the lower-grade material and poisoned millions of dollars worth of product.

|

Alumina Purity |

Max Temperature |

Best Applications |

Chemical Resistance |

Typical Cost |

|

95% Alumina |

1450°C |

Basic furnace work, general industrial |

Good |

Budget-friendly |

|

99% Alumina |

1600°C |

High-temperature processing, aerospace |

Very Good |

Mid-range |

|

99.7% Alumina |

1700°C |

Semiconductor, chemical processing |

Excellent |

Premium |

Always match purity to application choosing wrong grade costs more in failures than upgrading initially.

c) Quality Control Problems You Can’t See

I have seen more than a dozen ceramic tube producers around the globe. The shocking difference in quality is apparent. The high-end suppliers carry X-ray inspection and thermal cycling on all batches. Budget suppliers merely wish things would turn out well. I had once encountered a supplier that was using dirty raw materials their tubes were flawless in every way but none lasted more than a few weeks Look for manufacturers like Modanel Ceramics, LSP Ceramics, and IPS Ceramics with comprehensive quality control systems and demand documentation.

d) Installation Mistakes That Crack Expensive Tubes

Even the best ceramics insulator tubes and hollow ceramic tubes fail with bad installation. I saw a maintenance crew installing a $1,200 quartz tube to apply to a furnace with the usual steel clamps. They tightened too much and the tube ruptured on the initial heating. The long horizontal tubes were not properly supported at another facility, and 3 tubes were destroyed by thermal expansion stress in a single month. Provide support at every 30-40cm and thermal expansion movement.

e) Chemical Attacks Disguised as Heat Damage

I’ve analyzed failures where hydrofluoric acid ate through alumina tubes, but everyone blamed temperature. Advanced ceramic materials resist most chemicals, but not everything. For aerospace, automotive, or chemical processing applications, trace contaminants can create low-melting compounds that attack the ceramic surface. What looks like thermal damage is often chemical corrosion.

3. How I Evaluate Ceramic Tube Suppliers Now

After getting burned by bad suppliers, I developed a systematic evaluation process that’s saved millions in avoided failures.

a) Documents Every Good Supplier Should Provide

I request full material composition certificates, density, thermal expansion data and batch testing data on all ceramic tubes suppliers. When they fail to give details of documentation, I walk away. Good suppliers are open to questions regarding firing temperatures, grain size control, and contamination preventive action.

b) The Questions That Separate Good From Bad Suppliers

Each time I visit a ceramic tube manufacturer candidate, I ask difficult questions:

-

What is your internal reject rate?

-

How do I prevent contamination in manufacture?

-

Can you give me some thermal cycling test data?

Good supplier has detailed reply. Problem suppliers become defensive or give non-specific answers.

c) Why Technical Support Matters More Than Price

The finest ceramic tube suppliers can assist with optimized specifications of your applications. They give material selection advice, installation procedures recommendations, and failure analysis in case of problems. Such assurance can mean the difference between years of dependable operation and expensive recurring failure.

What’s Happening in the Ceramic Tube Market Right Now

The industrial ceramic market is changing fast. There are opportunities and risks that are being generated through supply chain consolidation. New technologies such as hot isostatic pressing and additive manufacturing are enhancing the quality at the cost of driving up the prices.

There is increasing demand by semiconductor production, electric vehicle batteries and aerospace, which is leading to supply constraints. The strategic buyers are also dealing with the way they are diversifying their supplier bases, and building strategic partnerships beyond simply purchasing on price. Whether sourcing alumina ceramic sheets, ceramic grommets, macro tubing, alumina washers, ceramic bars, or specialized components from ceramic tube UK suppliers, relationship-building matters more than ever.

Prevention Strategies That Actually Work

Never heat or cool alumina ceramic tubes faster than 5°C per minute above 1000°C. This is one rule that will help ward off most thermal shock failures. It worked in hundreds of installations I have seen.

And horizontal tubes are supported with ceramic or refractory supports at 30-40cm. Institute in furnace controllers the automatic ramping of programs and training of furnace operators in acceptable heating protocols. The visual checks that are done monthly prevent failures before they become costly.

The Real Cost of Cheap vs Quality Tubes

I monitor total cost of ownership of my clients. Budget tubes are cheaper at first, but have a life span of 6-12 months and sudden unpredictable failures. Emergency replacements run at 2-3x regular prices which include downtime losses.

Costlier premium tubes have a longer lifetime of 18-36 months with predictable, slow over time degradation. Maintenance replacements can be planned rather than on an emergency shutdown basis. Most applications have quality tubes, which are cheaper in the long run even though they are expensive to buy.

My Working Strategy That Works

Look, I have seen too many companies attempt to redesign everything all at once and make things worse. Begin by doing the smallest applications, those that really hurt when they go down, you know, those that bring your whole production line to a halt.

Make priorities of those. Look critically at the suppliers of tubes to these places.

-

Are they furnishing evidence to you?

-

Are they even able to inform you what they have in their ceramic?

Even spend some money to get some sample tubes and then really try them under your conditions before ordering large quantities.

This is what I tell my clients: slow growth. After you have sorted out your most important applications, then go to the next area of priority. Monitor what is and is not working. I really do maintain spreadsheets of failure rates and tube life under various conditions, it is nerdy but it works.

It may appear that this process would take too long, but I have seen companies reduce their tube failures by 80 percent or better in one year simply by making a concerted effort to be diligent.

When You Need Expert Help

Some times you require external help with complicated ceramic tube issues. It takes special knowledge to select materials in extreme conditions, analyze failure of recurrent issues, and evaluate suppliers objectively.

Most suppliers of ceramic tube offer consulting services, however, independent consultants do not place any sales pressure on their advice. Look for experience with similar applications and access to specialized testing capabilities.

FAQ’s

Do Ceramic Tubes Break?

No, there is no way to repair a cracked ceramic tube and they should be completely replaced because any repair would weaken the structure and introduce weak points in which failure can be catastrophic.

Are Special Storage Conditions Required of Alumina Tubes?

Yes, alumina ceramic tubes should be kept in dry conditions with less than 60 percent humidity, impact free, and to the room temperature to avoid moisture absorbing and micro-cracking.

Do Ceramic Tubes Have Industry Quality Standards?

Manufacturers of ceramic tube are expected to meet ASTM specifications of material testing, dimensional testing, and documentation of quality, but most suppliers forego the requirements to cut costs.

Conclusion

The failures of the alumina ceramic tubes can be avoided by choosing the materials and suppliers wisely. Don t focus on purchase prices, but look at total costs. By knowing the five most important failure points which I have identified, you will save thousands of dollars in emergency replacements and lost production. Select ceramic tube manufacturers that can offer full documentation, quality control systems and application engineering services in order to achieve permanent operation in your industrial processes.