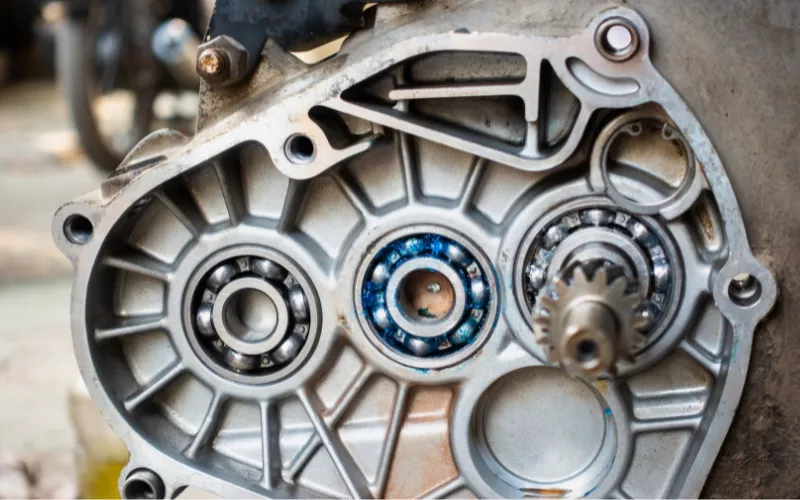

Steel bearings are difficult to operate under heat, stress and corrosive conditions and hence, they cannot be relied on in the critical systems. Siliziumnitridkeramik bearings (Si₃N₄)change that fact by offering exceptional temperature resistance, toughness and chemical resistance. As a matter of fact, to engineers who need accuracy and longevity, they provide consistent performance where steel fails.

Was ist Siliziumnitrid?

Si₃N₄ is a non-oxide ceramic that is made of silicon and nitrogen molecules that are bonded by an abnormally strong crystalline structure. Being in the category of advanced ceramic, it offers a performance profile, which the metals are unable to match.

High Thermal Stability

Si₃N₄ has a high thermal stability which implies that it does not melt away at high temperatures and therefore, the structure does not change at temperatures close to 1000 °C, the temperature at which steel bearings become soft and loses its strength. This is what makes it perfect in jet engines, turbines and semiconductor tools where continuity during the heat is a paramount concern. To operators, it translates into reduced failures, increased operating time and increased stability of the process.

Geringe Dichte

Silicon nitride is almost 60% lighter than steel, and this fact renders it a significant centrifugal force during high-speed rotation. The low weight does not merely minimize the energy usage, but also the strains in the surrounding parts. In practice, the lightness of bearings means that they operate faster and wear out less, which means efficiency and extends its life cycle.

Exceptional Fracture Toughness

Silicon nitride in comparison to brittle ceramics has an exceptional fracture toughness and can resist cracking even when subjected to sudden loads or thermal cycling. This durability is reflected in dependability in harsh conditions either in the drivetrain of a racing car or a high-end aerospace part that the bearings will not break when under shock, vibration, or sudden changes in speed.

Outstanding Hardness

Si₃N₄ is a substance that has an incredible wear resistance and the hardness that is over two times that of steel (around 700 HV). Bearings have their smooth, polished surfaces much longer; it has reduced friction and gives the lubricant a longer life and fewer maintenance cycles. In case of industries that operate 24 hrs, it would mean reduced stoppages and reduced replacement costs.

Excellent Chemical Resistance

Silicon nitride ceramic bearings have good chemical resistance to water, fuel, lubricants, acid and corrosive gases. Silicon nitride does not rust or corrode in an environment of corrosion, as it would with steel. This is especially applicable to semiconductor, medical and aerospace applications where even minor contamination can destroy whole production cycles or cause safety-critical systems to be impacted.

All these properties have caused silicon nitride to be among the most dependable and adaptable materials in high stress mechanical purposes. It also comes in handy particularly in rolling element bearings where performance, efficiency and reliability are not negotiable.

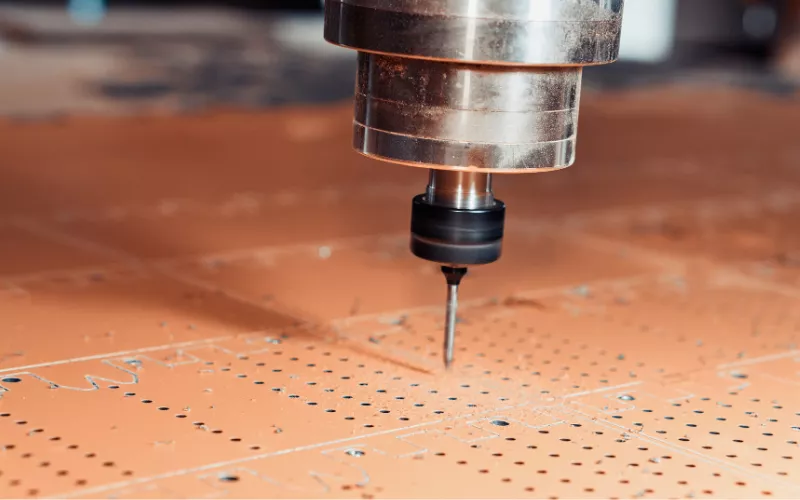

Why Processing Quality Matters

Although the properties of the raw material are impressive, the manufacturing quality is the determinant of the real world performance. Elaborate techniques like hot isostatic pressing (HIP) and gas-pressure sintering are used to produce silicon nitride to eliminate porosity and have a fine-grained structure.

Why this matters:

-

Dimensional Accuracy: It is observed that very minor variations in shape in high speed bearings may cause imbalance, vibration and early wear. Precision manufacture is used to make sure that all the balls and raceways are produced to micron-tolerances and bearings will be running at extremely high RPM. In the case of engineers, it will be a stable performance, reduced downtimes, and safe machines.

-

Low Porosity: This is the concealed flaw in ceramics. Minor holes in the material provide cracking stress points. The sintering techniques are developed to eliminate these gaps, providing silicon nitride bearings with much higher rolling fatigue strength. This in practice leads to long service life and lowered cost of maintaining.

-

Uniform Grain Structure: This is because the microstructure is not balanced, which means that the stress would be concentrated at selected positions, thus causing chipping and instant failure. Fine-grained silicon nitrate is uniform and it evenly distributes loads throughout the material. This enhances strength, durability and shock resistance and therefore the bearings are more dependable in harsh conditions like thermal cycling or high loads.

Even silicon nitride may be brittle without these specific processes, and this leads to failure. It is equally important to select a supplier with strict quality control measures as the material.

Silicon Nitride vs. Steel Bearings

When selecting bearings to be used in problematic applications, one should directly compare the material characteristics. The table below highlights the better performance that silicon nitride shows compared to traditional bearing steel in all aspects of performance.

|

Eigentum |

Siliziumnitrid (Si₃N₄) |

Bearing Steel (52100/440C) |

|

Maximum Operating Temp. |

≈1000 °C |

≤250 °C |

|

Dichte |

≈3.2 g/cm³ |

≈7.8 g/cm³ |

|

Bruchzähigkeit |

≈6–8 MPa·m^0.5 |

≈2–4 MPa·m^0.5 |

|

Härte (Vickers) |

≈1550 HV |

≈700 HV |

|

Korrosionsbeständigkeit |

Exzellent |

Poor–Moderate |

|

Wärmeleitfähigkeit |

≈25 W/(m·K) |

≈46 W/(m·K) |

|

Rolling Contact Fatigue |

Outstanding |

Mäßig |

Why Are Silicon Nitride Bearings the Best Choice to Use in High-Performance?

The versatility of silicon nitride (Si₃N₄) bearings is the fact that they can perform under extreme conditions, where steel bearings quickly fail. They are used in aerospace and medical devices because they are high in strength, thermal, and corrosion resistance, and therefore cannot be compromised in any industry where reliability, efficiency, and safety are paramount.

Luft- und Raumfahrt & Verteidigung

In the aerospace, every single component is tested in the most inhumane working conditions. Jet engines, fuel pumps and guidance systems bearings are exposed to intense heat, speed and vibration. The thermal and shock resistance of silicon nitride assists in steady operation at the point of freezing or deformation of steel. The light weight of the material also implies that the overall weight of the aircraft is lowered, and this results in increased fuel efficiency and increased mission reliability.

Automobilindustrie

The transition to electric vehicles (EVs) and the necessity to have extremely efficient motorsport parts have contributed to the increased rapid adoption of ceramic bearings. The Si₃N₄ is thinly packed in EV motors to increase range and efficiency by reducing the rolling resistance. Its ability to resist wear during high-speed loads implies the increased life span and in the context of motorsport, its hardiness implies consistent performance during loads in rapid acceleration, braking and cornering.

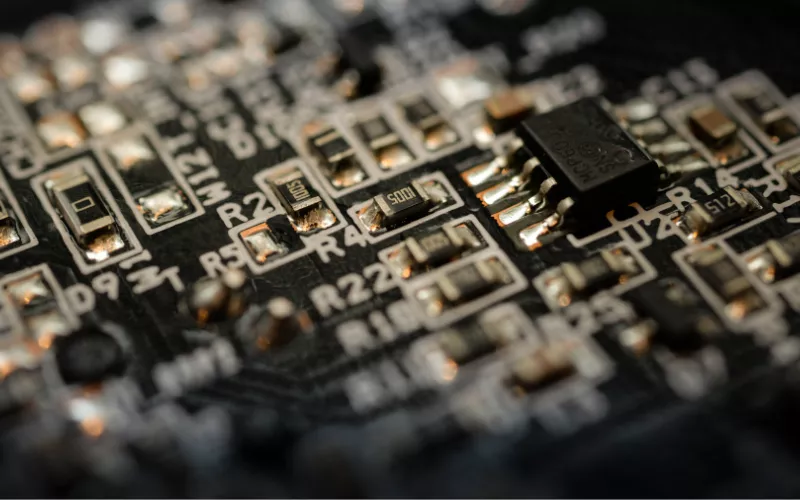

Halbleiterfertigung

The purity and precision with which the production of semiconductor is required are unmatched in few industries. Vacuum pumps, wafer-handling, and CVD reactors bearings should be able to run without causing contaminants. The high chemical resistance of silicon nitride ensures that it does not react with the gases in the process, and the low wear characteristics ensure that wafers do not have any defects. Si₃N₄ ensures the quality of products and equipment availability in an industry where a single particle can ruin a whole batch.

Energie

In the energy industry, the components should be capable of sustaining extended service periods in hostile conditions. Silicon nitride has a high resistance to corrosion and high rolling fatigue strength, which is advantageous in bearings of wind turbines, nuclear plants, and fuel cells. In the case of wind turbines, the bearings of Si₃N₄ are lighter, which creates a system of minimal mechanical stress. Their chemical inertness in nuclear and fuel cell projects gives long term safe operation under hostile thermal and chemical conditions.

Medizinische Geräte

Dental procedures and surgical apparatuses that require high speed require bearings which can rotate at high RPMs without heat generation or pollution of sensitive areas. The hardness of Si₃N₄ (about 1550 HV) and it has low friction which makes it the material of choice when it comes to reliable and sterile medical practices. The patients enjoy the advantages of hassle-free operations, and the medical practitioners enjoy having tools that last longer in service and need less maintenance.

Industrial Machinery

Bearings used in industrial equipment, such as pumps and compressors, robotics and high speed spindles must be able to resist repetitive and high load stress. Silicon nitride bearings are ideal in such kind of environments due to their wear resistance and durability, which reduces the number of unscheduled downtime. The lightness in robotics enables them to be moved faster and more accurately and in machining, they are stable with continuous rotation at high speed, hence giving consistent quality of the products being made.

Which Should You Select?

Depending on the operating conditions, cost priorities and tolerance to risk, the choice of steel vs. silicon nitride bearings is determined. The following table explains the material best suited in each case, and assists the engineers and decision-makers in matching material selection with the performance and budgeting needs.

|

Criteria |

Stahllager |

Silicon Nitride Bearings |

|

Temperature Range |

Operates up to 250°C |

Handles heat up to 1000 °C |

|

Process Environment |

Normal, low stress use |

Harsh, high speed, or corrosive use |

|

Budget Sensitivity |

Best when the focus is on cost only |

Best when the performance is the most important factor |

|

Lubrication Needs |

Needs frequent lubrication |

Needs moderate lubrication |

|

Failure Impact |

Cheaper and easy to manage. |

Failure can be costly or devastating, and is much easier and cheaper to manage. |

What is the Secret to Finding the Right Supplier?

Selecting the right supplier is no less important than the selection of the right material. Even the finest silicon nitride bearings are performing poorly unless the manufacturing quality, purity and support standards are obtained. The following are the main considerations to make before making a purchase.

-

Purity: High purity silicon nitride will reduce impurities that may lead to a limitation in the ceramic or a chemical reaction in sensitive situations. At least a purity level of 99% ensures the identical strength, better chemical stability and long time reliability, particularly in aerospace and semiconductor.

-

Dimensional Precision: Bearings must be able to achieve micron tolerances to be able to operate at high RPM. The presence of a supplier that provides accuracy in machining and rigorous testing is beneficial in assuring that the bearings will be balanced, have low vibration, and offer a stable performance in the vital systems.

-

Performance Data: Suppliers who had fatigue tests, thermal cycling and loads recorded results are considered reliable. Access to this information enables engineers to provide counterarguments to assertions, as well as to identify the bearings with reference to their operating conditions.

-

Customization: There are no two identical applications. The major suppliers must be in a position to offer the flexibility to design hybrid or full ceramic bearings that address the special needs, including special load capacity, lubrication or environmental issues.

-

Technical Support: Quality suppliers do not just sell merchandise. They help in technical support, design support, quick response to orders and quality after sales services. This collaboration implies that customers can successfully combine Si3N4 bearings, and they can solve issues fast.

Maintenance Practices

Even the hardest kinds of ceramics need to be handled and taken care of in order to attain its maximum life in service. The following best practices will decrease the risk of premature failure and will allow the safe work in extreme conditions.

-

Heat/cooling: Sudden change of temperature should not be applied to bearings. Slow cooling and heating will avoid the problem of thermal shock that can lead to the formation of micro-cracks and performance affects. Controlled cycles also achieve a long service life when there are repeated startups and shutdowns.

-

Lubricant selection: It is possible to select lubricants that are either specially designed to operate at high temperature or in ceramics, such as solid-film lubricants in which the conventional oils decompose. The correct lubricant allows less friction, restrains wear and provides smooth operation in extreme conditions.

-

Periodic checks: Micro-cracks, surface wear and contamination should be checked on a regular basis. Early detection implies that small issues do not turn into disastrous failures, without downtime and cost of repair.

-

Proper storage: Bearings should be kept in a dust free and clean place. Cushioned packaging can be used to avoid chipping or edges damage. Before it is even installed, stacking or careless handling may destroy the ceramic structure.

-

Light treatment: Silicon nitride is very durable, but is not puncture resistant. There should be no direct contact between metals and ceramics, and recommended equipment should be used. Careful handling is done to maintain precision and strength of the bearing.

These process guarantees the highest life of the service, improves the reliability of operations, and safeguards the investment of high performance silicon nitride bearing.

Abschluss

Silicon nitride ceramic bearings are no alternative of steel and are not a mere upgrade, but a strategic one. Si₃N₄ bearings can resist temperatures up to 1000 °C, resist corrosion and operate reliably at very high speeds, which are considered to be better in the conditions with high cost of failure.

In the case of aerospace, automotive, semiconductor and energy industries, the switch to silicon nitride bearings can be translated into increased uptime, lowered maintenance expenses and safety. Making a switch is not simply a performance factor, it is an excellent investment in long term consistency and economic effectiveness.