Einführung

The performance of your electronic device depends on the type of base material you use. A Keramiksubstrat will provide you with improved heat control, durability, and insulation. That is why it is the most appropriate in various industries.

The selection of the appropriate ceramic substrate is not only related to performance, but also long-term reliability and cost-effectiveness.

What Is a Ceramic Substrate?

A ceramic substrate is a base material that can be used to mount and interconnect electronic circuits. Ceramics provide high stability at elevated temperatures and high electrical insulation as opposed to organic substrates.

They also exhibit reduced Wärmeausdehnungskoeffizient (CTE). Thus reducing the stress levels between substrate and mounted components when heating and cooling occur. PCB manufacturing using ceramic circuit board material has increased heat dissipation, reduced signal loss, and extended device life cycles.

Due to these benefits, ceramic substrates have found extensive application in hybrid integrated circuits, semiconductor packaging, and advanced microelectronics.

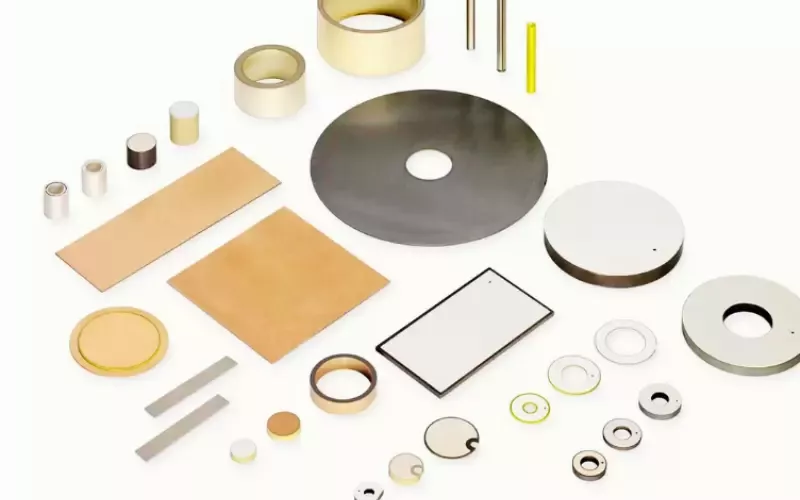

Types of Ceramic Substrate Materials

Ceramic substrates are not one-size-fits-all. Applications have different needs in terms of material properties. In the case of ceramic substrates, Aluminiumoxidkeramik Und Aluminiumnitridkeramik substrates are the two most common materials used.

Both of them are good base materials in electronics, but they differ in characteristics and can be applied to different purposes.

The two most used types are:

1. Alumina Ceramic Substrate (Al₂O₃)

-

Well-known for affordability and performance.

-

Offers both good electrical insulation and good thermal conductivity (20–35 W/mK).

-

Widely found in consumer electronics, LED modules, and generic PCB designs.

I once had to work with a team that produced LED drivers for street lights. We were using alumina ceramic substrates since the project required a low-cost but dependable choice. They could deal with the heat without pushing the prices too high.

2. Aluminum Nitride (AlN) Substrate

-

Extremely high in thermal conductivity in comparison to alumina (170–230 W/mK).

-

Ideally suited to high-power and high-frequency equipment.

-

More costly, but important when efficient heat-dissipation is needed, like power electronics and RF modules.

Once, an aerospace industry client requested a solution in which heat failure was a significant threat. The only option available that could handle the load while maintaining a low weight was aluminum nitride substrates.

Alumina ceramic substrates and aluminum nitride substrates are considered as the same family of ceramic substrate materials. However, the properties and applications may vary. Therefore, engineers have flexibility in selecting the substrate they use depending on the needs of the project.

Other High-Performance Ceramic Substrates

Along with alumina ceramic substrates and aluminum nitride substrates, two ceramic substrate materials are important in power electronics and high-reliability systems. These materials, silicon nitride (Si₃N₄) Und Siliziumkarbid (SiC), provide unique benefits that make them suitable for demanding applications.

Silicon Nitride (Si₃N₄) Substrate

-

Excellent fracture toughness which is ~7 MPa·m½ (ISO 20501:2024)

-

Strong mechanical reliability and resistance to thermal shock.

-

Extensively used in power modules for automotive and industrial applications.

Silicon Carbide (SiC) Substrate

-

Very high thermal conductivity (~120 W/mK).

-

Excellent chemical stability and temperature resistance (>1000°C).

-

Suitable for high-power, high-frequency, and harsh-environment applications.

Both Si₃N₄ and SiC are increasingly favored in next-generation power electronics where mechanical robustness and heat management are equally important.

Properties Of Ceramic Substrates

Ceramic substrates provide various electrical, thermal, and mechanical properties that cannot be provided by conventional materials. Their performance is essential to industries that are high-powered, high-frequency, and extreme. Both properties lead to reliability and efficiency in applications. Let’s take a closer look at the most important factors:

Wärmeleitfähigkeit

High thermal conductivity is one of the most valuable characteristics of ceramic substrates. Aluminum nitride is a very good heat conductor with a value of about 170-230 W/mK. That is why they can be used in areas where the devices need efficient heat dissipation. For example, LED modules or power devices.

In comparison to this, Alumina conducts lower, about 20-35 W/mK. Both are better than FR4, which is close to 0.2- 0.5 W/mK. It can be used in general electronic applications, but not in extreme heat conditions. Moreover, SiC has a thermal conductivity of ~120 W/mK.

I once worked on a project involving lighting, and the LED boards were breaking down. Replacement of FR4 substrates with AlN substrates fixed the problem. The heat management difference was fast and obvious.

Durchschlagsfestigkeit

Durchschlagsfestigkeit is the capacity of a material to withstand high voltages of electricity. Ceramic substrates have better dielectric qualities, thus providing insulation and avoiding short circuits even in small designs. This feature allows them to be used in high-frequency applications and high-tech electronics.

Alumina substrates have high dielectric performance (~10–15 kV/mm). Moreover, AlN has high dielectric strength (~12–15 kV/mm) and excellent thermal performance. So, it offers a balance between insulation and thermal performance. However, FR4 dielectric strength is ~8–12 kV/mm.

I once tested a high-frequency amplifier that melted because of poor insulation. With the replacement of ceramic substrates, the unit operated at high voltage without breakdowns.

Coefficient Of Thermal Expansion (CTE)

Coefficient of Thermal Expansion (CTE) plays a major role in compatibility between the substrate and the mounted electronic parts. When there is a mismatch in CTE, the cracks or failures may occur during heating and cooling down of the device.

Alumina ceramic substrates (~6.5-9.4 ppm/°C) generally offer slightly better CTE than AlN (~4.5-5.6 ppm/°C). However, AIN is closer to the expansion rates of silicon chips (~2.6-3.3 ppm/°C) than organic substrates such as FR4 (~13-18 ppm/°C). This alignment minimizes solder joint stress and keeps the greater level of reliability on the equipment.

I recall the experiment with a series of boards. In this, the FR4 was a source of stress in the joints after recurrent heating. In the case of AlN, the joints were also stable when subjected to long thermal cycles.

Mechanische Festigkeit

Ceramic substrates are said to be mechanically strong. Specifically, Alumina has a high hardness and wear (~350–400 MPa), so it can be used in harsh conditions. This strength holds the substrate in place. So that it does not readily deform or disintegrate under stress during assembly or operation.

Though a little brittle, AlN still provides enough strength (~300–320 MPa) in precision electronics where thermal and mechanical properties are important. However, FR4 mechanical strength is ~200–250 MPa, and Si₃N₄ has even higher toughness (7 MPa·m½ fracture toughness).

Once when handling an assembly job, I dropped a tray of alumina substrates. Surprisingly, the majority got through without a scratch. This kind of durability saves cost and time in the process of handling.

Reliability In Harsh Environments

The ceramic substrates are made to work in extreme conditions. They are resistant to high working temperatures, exposure to moisture, and even corrosive chemicals. As an example, in an environment where organic materials would deteriorate, they do not deteriorate. You know what? All ceramics withstand >1000°C, unlike FR4 (<300°C).

This is what makes ceramics the material of choice in Luft- und Raumfahrt, Automobilindustrie, and defense Elektronik, where stress reliability is a requirement. They have an advantage over traditional materials in their ability to resist thermal shock and perform well under demanding conditions.

Ceramic Substrate Manufacturing Process

The ceramic substrate manufacturing process is an accurate technique that needs attention to detail during all stages. It starts with the selection and preparation of raw materials. Then shapes and thermal treatment, the surface finishing, and quality inspection.

These measures make the end product capable of providing high-level performance in a challenging electronic environment.

Powder Preparation:

The ceramic substrate manufacturing process begins with powder preparation. It is prepared then with high-purity alumina or aluminum nitride powders, refined to a required uniform particle size and chemical purity. Since even small contaminants can have an impact on the electrical and thermal performance of the end product. Ceramic powder preparation is a necessary step.

Homogeneity is achieved by a restricted milling and mixing process that stabilizes results at a further stage.

Bildung:

After the powder is prepared, it is then rolled into what are known as green bodies. Depending on the design needs, techniques such as pressing, tape casting, or slip casting are used. The thickness, density, and flatness are directly influenced by the forming process. It is a very important step to decide how the substrate is going to perform in real circuits.

Firing:

The green bodies are then sintered at high temperature, which binds the particles together to a solid and mechanically strong structure. The ceramic attains its ultimate crystalline form and microstructure during firing. These factors contribute to its high thermal conductivity and longevity.

Proper temperature and atmosphere control avoid various defects like warping or porosity.

Finishing:

Finishing processes like polishing of the substrates and metallization of the surfaces, are applied to the substrates after firing. The processes help achieve high-fidelity dimensions, planar surfaces, and conductive layers, which can be integrated with ceramic circuit board material.

The finishing process also leads to the reliability enhancement as the substrate is ready to connect with the electronic equipment. Each stage of the ceramic substrate manufacturing process directly impacts performance and reliability

Key Process Technologies in Ceramic Circuit Board Material

Beyond basic ceramic preparation, advanced processes integrate metals and circuits to meet the strict demands of high-performance electronics. Each process adds a unique advantage to the ceramic substrate manufacturing process, ensuring reliability in thermal, mechanical, and electrical performance.

DBC (Direct Bonded Copper)

This process bonds copper directly to the ceramic surface through a high-temperature reaction. Copper layer thickness is typically 300–600 μm as per IEC 62326-1-2025. It provides excellent thermal conductivity and low electrical resistance. This makes it a preferred choice for high-power modules such as inverters and automotive power systems.

DPC (Direct Plated Copper)

DPC allows thin copper layers to be plated with extreme precision. It enables fine circuit patterns, higher wiring density, and reduced signal loss. This makes it suitable for high-frequency devices, RF circuits, and miniaturized electronics where performance and size both matter.

Once, I worked with a team designing an inverter system. Then, switching to DBC with ceramic circuit board material solved our overheating problem. The module handled thermal cycling without failures, which saved costly redesigns.

AMB (Active Metal Brazing)

AMB uses an active brazing alloy to form strong and reliable copper-to-ceramic bonds. This method ensures excellent adhesion, even under thermal cycling and mechanical stress. Moreover, Brazing temperature is usually 800–900°C (standard JIS C 6480-2025). This is why it is widely applied in industrial power electronics and aerospace-grade systems.

I remember testing aerospace-grade power electronics where reliability was non-negotiable. Using AMB with ceramic circuit board material gave the modules both the strength and heat resistance needed for flight conditions.

Key Differences of Ceramic Vs Organic Substrate

Ceramic substrates have significant differences when compared to organic substrates such as FR4. FR4 is a glass-reinforced epoxy laminate that is commonly used in standard printed circuit boards. This is because of its low cost and simple processing.

However, it cannot be compared with high power and high frequency because it possesses less thermal conductivity and higher CTE.

Ceramic substrates, however, have superior heat dissipation, mechanical, and electrical insulation properties. They are very costly, but reliable in harsh environments where FR4 is not, and they are reliable. Here’s the main ceramic vs organic substrate difference:

|

Eigentum |

Ceramic Substrate (Alumina, AlN, Si₃N₄, SiC) |

Organic Substrate (FR4) |

|

Wärmeleitfähigkeit |

High (Alumina 20–35 W/mK, AlN 170–230 W/mK, SiC ~120 W/mK) |

Low (FR4 0.2–0.5 W/mK) |

|

Durchschlagsfestigkeit |

Superior (Alumina 10–15 kV/mm, AlN 12–15 kV/mm) |

Moderate (FR4 8–12 kV/mm) |

|

CTE Compatibility |

Close to silicon ( AlN 4.5–5.6 ppm/°C, Alumina 6.5–9.4 ppm/°C, close to silicon (2.6–3.3 ppm/°C) |

Higher mismatch (FR4 13–18 ppm/°C) |

|

Mechanische Festigkeit |

High (Alumina 350–400 MPa, AlN 300–320 MPa, Si₃N₄ toughness 7 MPa·m½) |

Lower (FR4 200–250 MPa) |

|

Temperaturbeständigkeit |

>1000°C |

<300°C |

|

Kosten |

Höher |

Untere |

|

Reliability |

Excellent in harsh conditions |

Beschränkt |

Ceramic vs Organic Substrate Performance Comparison

FR4 (organic substrate) is the industry standard for cost-sensitive boards, but it cannot compete with ceramic in advanced or high-reliability applications. The choice of ceramic vs organic substrate often depends on the performance requirements of the system.

-

Heat Management: Ceramic substrates such as AlN and SiC can dissipate heat more than 100 times faster than FR4. This superior thermal conductivity is critical in high-power electronics. Excess heat can reduce efficiency, shorten component lifespan, and lead to system failure.

-

CTE Matching: Ceramics align more closely with the coefficient of thermal expansion (CTE) of silicon chips. This reduces solder joint stress during temperature cycling. It also improves long-term reliability in demanding environments, such as automotive inverters or aerospace modules.

-

Mechanical and Environmental Reliability: Ceramic substrates maintain structural stability at temperatures above 1000°C and resist moisture, corrosion, and harsh chemicals. FR4, on the other hand, begins to degrade when exposed to 250–300°C. This makes it unsuitable for advanced power modules or defense-grade systems.

In short, FR4 substrates are well-suited for low-cost consumer electronics. But when performance, reliability, and durability are the priority, ceramic substrates become essential for applications in power modules, aerospace, defense, and high-frequency communication devices.

Why Choose GORGEOUS for Ceramic Substrate Materials

At GORGEOUS, we do not just offer substrates, but we offer innovative solutions that match the needs of modern industries. We produce trustworthy materials that are performance-based and adaptable. As one of the best ceramic substrate manufacturers, we are trusted by business owners all over the world.

Premium Materials

Our alumina and aluminum nitride are of high purity. They have outstanding thermal conductivity, mechanical strength, and electrical insulation. These properties enable our ceramic substrates to be used in a large variety of applications.

Advanced Processing

Our team uses precision forming, controlled firing, and professional finishing to produce substrates of consistent structure and consistent performance. The high-quality processing provides the long-term stability and uniformity of all of our batches.

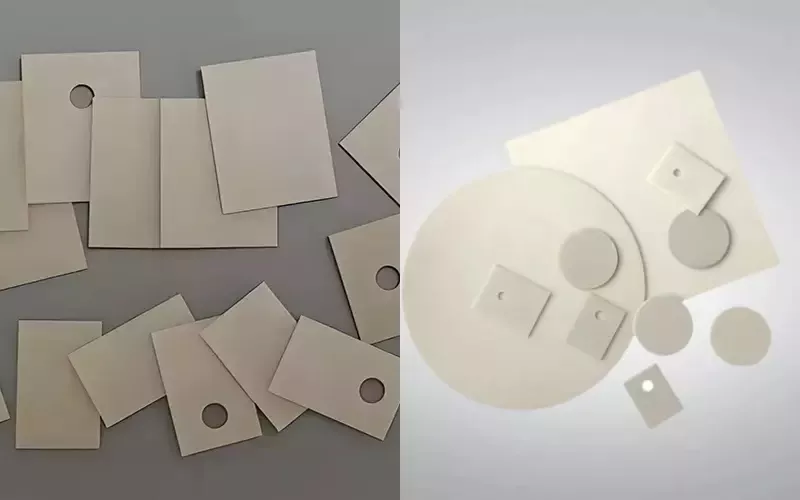

Anpassung

We know that no project is the same. So, we provide customized solutions to satisfy individual design, dimension, and performance needs. Standard substrates or custom-engineered designs, we are flexible so that your requirements are just what you need.

Strict Quality Checks

All substrates are highly tested, such as thermal conductivity test, dielectric testing, and dimension checks. Such checks will ensure that only high-performing and reliable products are delivered to our customers.

In short, partnering with experienced ceramic substrate manufacturers gives you access to material expertise that helps optimize both cost and performance.

Abschluss

Ceramic substrates provide superior strength, thermal, and electrical performance in demanding applications. With the appropriate supplier, reliability and innovation are a sure future for high-technology electronics.

Collaborate with GORGEOUS to access the best materials, expert advice, and reliable supply. Talk to us today and get your innovations moving with the right substrate!

FAQs

Q1: What are ceramic substrates used for?

Ceramic substrates are used in electronics, automotive, aerospace, and energy industries to provide mechanical strength, thermal control, and insulation to devices.

Q2: Are ceramic substrates better than FR4 boards?

Yes, the ceramic has greater thermal stability, dielectric strength and reliability in extreme environments than FR4.

Q3: Are ceramic substrates environmentally friendly?

Yes, ceramic substrates are non-toxic, recyclable, and more sustainable than a range of organic options.

Q4: How do I choose the right supplier for ceramic substrates?

Consider factors like material type, application requirements, certifications, and the reputation of the supplier.