INTRODUCTION

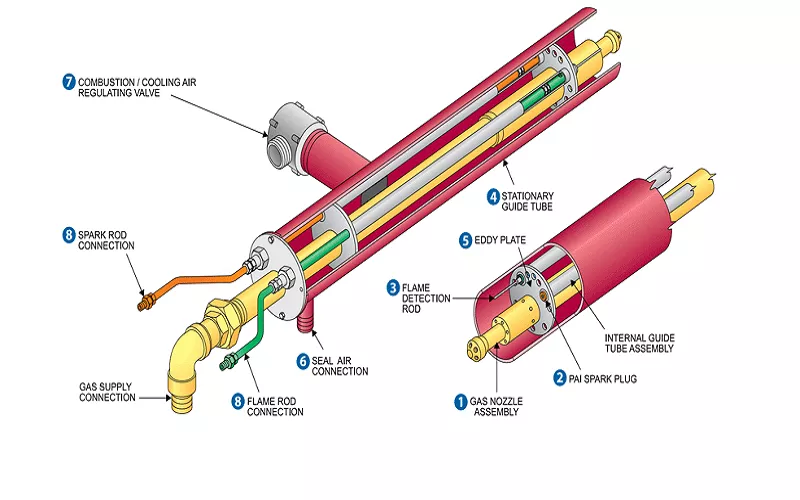

Diagram 1: Biomass Boilers Igniters

Have you ever wondered how biomass boilers ignite without a match or gas flames? That’s because of biomass boiler igniters. They are the real spark behind most of these renewable energy heating systems. Let’s find out how they work and why they are so popular today.

Characteristics of Biomass Boiler Igniters

A biomass boiler igniter is a special device that ignites the fuel in a biomass boiler. Organic matter, such as wood pellets and agricultural waste, is used as fuel in biomass boilers. Once they are ignited by these boiler ignitors, heat is generated for use. The boiler ignitor is one major component of biomass boiler igniters. Since no one enjoys lighting pellets by hand every time, Boiler igniters help kickstart the fire automatically, making the whole system cleaner, faster, and more convenient.

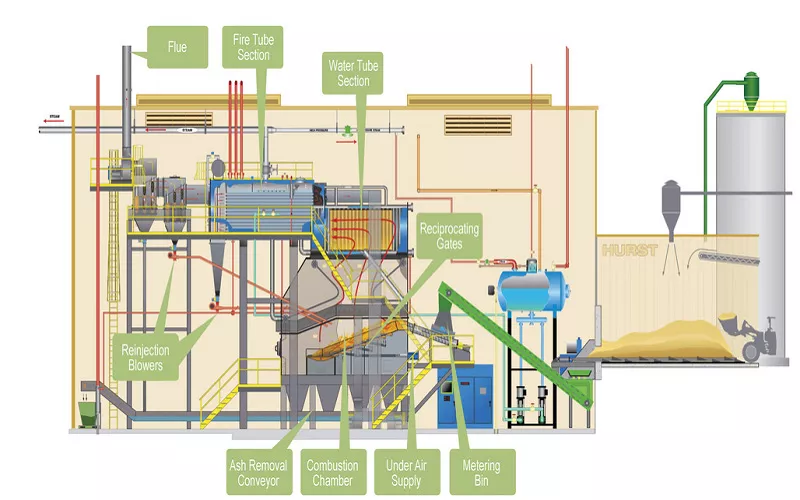

Diagram 2: Parts of a Boiler Igniter

They are now being used in offices, homes, industries, and many other places where heating needs arise. The best thing about them is their efficiency and speed, while saving energy.

Here are some of the key features of biomass boiler igniters that have made them so popular today:

-

They have an operating temperature of 800 °C - 1,200 °C.

-

They take between 3 - 8 seconds to reach full temperature.

-

They have a power rating of 150 W - 400 W, although some can reach up to 600W.

-

They have a voltage of about 10 V - 240 V AC

-

They have a lifespan ranging from 10,000 - 100,000 ignition cycles.

-

They have a thermal conductivity of about 20 - 30 W/m·K

-

Their dielectric strength is 10 kV/mm (especially for ceramic boiler igniters)

-

Their coefficient of thermal expansion is 7 - 8 × 10⁻⁶ /K

-

They have an operating environment temperature ranging from 20 °C to +300 °C.

How Does a Biomass Boiler Igniter Work?

A biomass boiler igniter works as the spark plug of the entire heating system because it helps ignite a fire when needed. Its entire process is very simple and interesting. First, when the boiler starts up, electricity flows into the igniter, heating it quickly to extremely high temperatures, usually between 800°C and 1,200°C. This heat is then directed toward the biomass fuel, be it wood pellets or chips. Within a matter of seconds, the surface of the fuel starts to glow, smoke lightly, and then it produces a flame.

Diagram 3: How a Biomass Boiler Igniter Works

Once the fire is started, the igniter automatically switches off to allow the main combustion process to take over. Everything is clean, controlled, and automatic. You don’t have to light any matchsticks or a lighter. In most heating systems, in-built sensors monitor the flame and temperature, ensuring the ignition happens only when needed, saving you time and energy. It is indeed very reliable and reproducible.

Types of Biomass Boiler Igniters

There are different types of biomass boiler igniters available for you to choose from. Each type has its own pros and cons, so choosing the right one depends on factors such as the kind of fuel you intend to use, your biomass boiler design, and how much heat your system needs to start a fire.

Here are some of the biomass boiler igniter types that top the charts:

-

Ceramic Igniters:

It’s easy to call them the people’s favorite. They’re an absolute work machine. They heat up so fast, reaching about 1000°C within the blink of an eye. You will find most of them made from advanced ceramics like silicon carbide or alumina. This makes them strong, clean, efficient, and reliable; little wonder, they rule the market.

-

Quartz Tube:

These types of boiler igniters are very bright burners. Most people buy them because of their sleek and transparent appearance. Quartz igniters use internal coils sealed in glass-like tubes. You will enjoy smooth and quick ignition while using them.

-

Metal Igniters:

These ones are built for durability and steadiness in smaller biomass units. They use steel casings or metallic heating elements. While they may not glow as fast as ceramics or quartz, they’re very rugged, easy to replace, and affordable as well.

-

Hot-Air Igniters:

These are the types you can call “silent heaters”. They don’t necessarily need to touch the fuel directly before starting fires. All they do is blow super-heated air into the burner to ignite the biomass. They are also very efficient, clean, and require low maintenance.

-

Infrared Igniters:

Infrared radiation is used by infrared igniters to quickly heat up biomass. They do this with very minimal contact. They are specifically built to be fast and energy-saving in automated systems.

Applications of Biomass Boiler Igniters

The applications of biomass boiler igniters are numerous. They have a wide range of usage in manufacturing industries, engineering, households, and offices. In fact, they’re used almost everywhere.

Here are some of the numerous applications of these biomass boiler igniters.

-

You can use them in household pellet stoves or as automatic ignition in home heating systems.

-

Industrial biomass boilers are used in factories and plants for large-scale steam or heat production.

-

Greenhouse heating systems need them to maintain consistent heat/warmth for crop growth.

-

Biomass power plants use these biomass boiler igniters for starting combustion in renewable energy generation.

-

You will also find them in commercial heating systems, in hotels, schools, and even hospitals that prefer to use eco-friendly fuel sources.

Biomass boiler igniters aren’t just about the heat; they also represent smart control. Interestingly, many modern ones use self-regulating technology (PTC) that adjusts power automatically to prevent the system from overheating. Some even feature in-built sensors and Artificial Intelligence (AI) based ignition timing. This, in turn, helps to boost the lifespan and fuel efficiency of the biomass boiler. Some advanced models also feature moisture detection, automatic restart, and energy-saving standby modes, making your ignition smarter, faster, and nearly maintenance-free. You most likely wouldn’t have been enjoying today’s greener combustion systems if not for the big role played by these boiler ignitors.

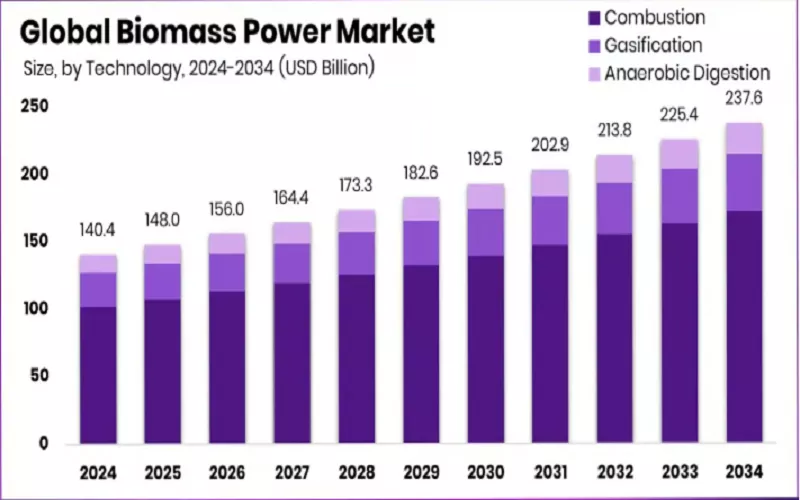

Global Market Size and Market Value of Biomass Boiler Igniters

Diagram 4: Global projection of Biomass Boilers

Due to the global shift towards clean and renewable energy, the over-reliance on fossil fuels has drastically reduced. Automatically making biomass systems emerge as a practical solution to meet clean energy and heating needs. As of 2024, the global market size for biomass boiler igniters was valued at $13.4 billion (Global Market Insights). Currently, the Compound Annual Growth Rate (CAGR) stands at 8.4% - implying that the market will most likely grow to about $30 billion by 2033.

Are you interested in investing? Now may be the best time to get in. Also, if you’re among those looking to purchase these biomass boiler igniters, these are some top market suppliers:

-

GORGEOUS CERAMICS, China

-

FKK Corporation, USA

-

Crystal Technica, UK

-

Polluxinte Electric Heating Solutions, China

-

HERZ GmbH, Austria

-

Leister Tools AG, Switzerland

-

DURAG Group, Germany

-

SUNSRAYS Heating Science & Technology Co., Ltd., China

-

FPS Ignitors, Canada

Now, before purchasing these biomass boiler ignitors, ensure you do these:

-

Request for the right specifications in terms of power rating, voltage, operating temperature, cycles, flame time, etc.

-

Ensure that the boiler igniter is compatible with your biomass fuel type (pellet, chips, straw, etc.)

-

Lastly, you can also confirm if warranty and installation services are available.

Frequently Asked Questions

How hot can these boiler igniters get?

They can get really hot within a few seconds. The majority of them get as hot as 900°C - 1,200°C. That intense heat generated is what burns the biomass (wood pellets).

How do I know when to replace my boiler ignitor?

Once your boiler ignitor fails to ignite, takes longer to start, or shows uneven burning, then it’s time to replace it.

How long should a boiler igniter last?

It depends on the usage. Although quality ceramic igniters are very reliable because they can last 10,000 - 100,000 ignition cycles.

Conclusion

As the world shifts to renewable energy solutions, these biomass boiler ignitors will keep leading the way forward. They may be small, but they play a very important role in generating heat and producing efficient energy systems. From lighting up wood pellets and biomass to stabilizing and reducing heat loss, they’re the absolute best. With the amazing properties they possess, it’s safe to call them the heartbeat of any revolution in eco-friendly heating.